KOMATSU PC1800-6 GALEO HYDRAULIC EXCAVATOR FIELD ASSEMBLY INSTRUCTION MANUAL SEAW003503 – PDF DOWNLOAD

DESCRIPTION:

KOMATSU PC1800-6 GALEO HYDRAULIC EXCAVATOR FIELD ASSEMBLY INSTRUCTION MANUAL SEAW003503 – PDF DOWNLOAD

SERIAL No. 10011, 11002 and up

POINTS REGARDING LOCAL ASSEMBLY:

Selection of work place:

- The work place should be suitable for the machine. The following points should be considered . • Area • Hardness of ground surface • Levelness • Entry/exit roads, turning space Assembly work on the hydraulic circuit must not be carried out in any place where dust or rain can get into the circuit during the operation .

- If the work is carried out outside, avoid places where there is rain or strong wind . Preparation and checks of lifting tools and jigs Check each lifting tool and jig thoroughly. In particular, check stands and blocks made of wood to check that the inside is not rotted or cracked . A Checks during actual operation

- Apply the parking brake of the trailer and crane securely, then put blocks under the wheels . Lower the pressure and temperature of the engine, hydraulic oil, and cooling water before starting work. When starting the engine, always give an agreed signal, &such as blowing the horn, to warn the people around the machine. Check also that the work equipment levers and travel levers are in neutral, and that the fuel control lever is at the low idling position. Be careful to maintain the balance of parts being lifted by the crane. Do not allow unauthorized persons into the working area .

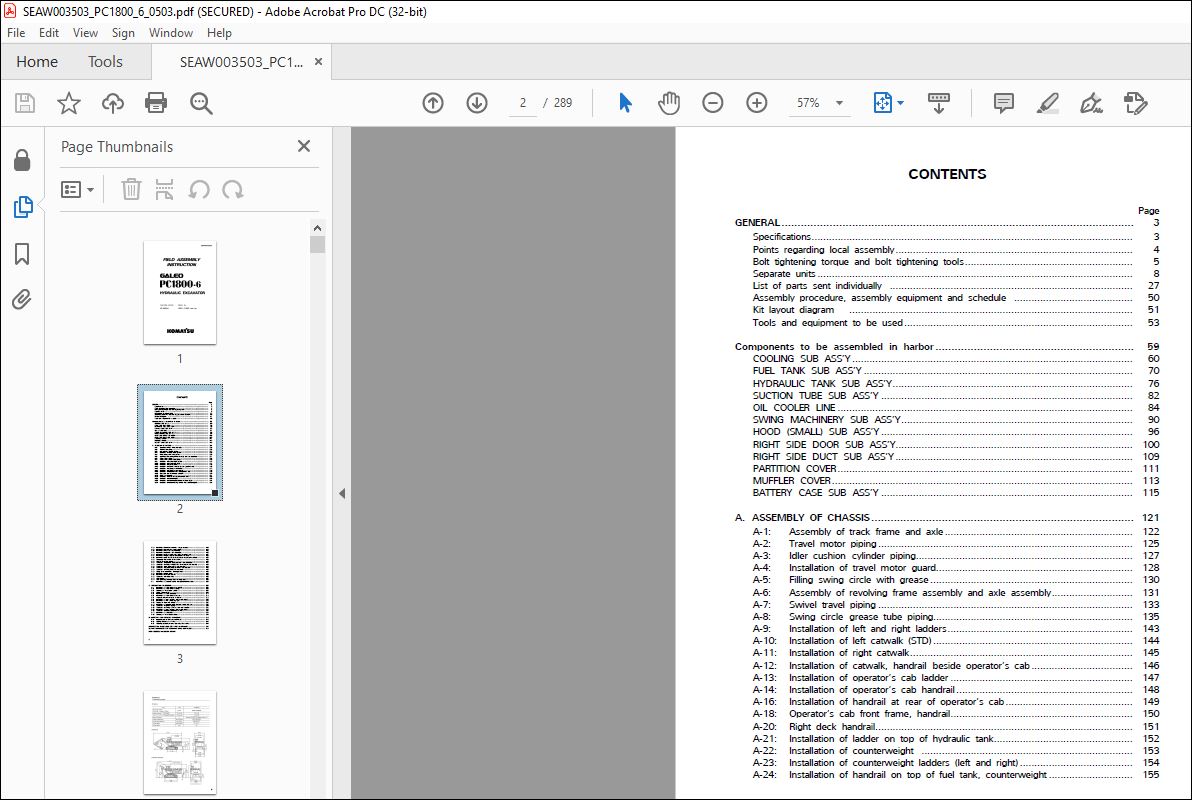

TABLE OF CONTENTS:

KOMATSU PC1800-6 GALEO HYDRAULIC EXCAVATOR FIELD ASSEMBLY INSTRUCTION MANUAL SEAW003503 – PDF DOWNLOAD

COVER 1

CONTENTS 2

GENERAL 4

1 SPECIFICATIONS 4

2 POINTS REGARDING LOCAL ASSEMBLY 5

3 BOLT TIGHTENING TORQUE AND BOLT TIGHTENING TOOLS 6

4 SEPARATE UNITS 9

5 LIST OF PARTS SENT INDIVIDUALLY 28

6 ASSEMBLY PROCEDURE, ASSEMBLY EQUIPMENT AND SCHEDULE 51

7 KIT LAYOUT DIAGRAM 52

8 TOOLS AND EQUIPMENT TO BE USED 53

COMPONENTS TO BE ASSEMBLED IN HARBOR 60

COOLING SUB ASS’Y 61

FUEL TANK SUB ASS’Y 71

HYDRAULIC TANK SUB ASS’Y 77

SUCTION TUBE SUB ASS’Y 83

OIL COOLER LINE 85

SWING MACHINERY SUB ASS’Y 91

HOOD (SMALL) SUB ASS’Y 97

RIGHT SIDE DOOR SUB ASS’Y 101

RIGHT SIDE DUCT SUB ASS’Y 110

PARTITION COVER 112

MUFFLER COVER 114

BATTERY CASE SUB ASS’Y 116

A ASSEMBLY OF CHASSIS 121

A-1: ASSEMBLY OF TRACK FRAME AND AXLE 122

A-2: TRAVEL MOTOR PIPING 125

A-3: IDLER CUSHION CYLINDER PIPING 127

A-4: INSTALLATION OF TRAVEL MOTOR GUARD 128

A-5: FILLING SWING CIRCLE WITH GREASE 130

A-6: ASSEMBLY OF REVOLVING FRAME ASSEMBLY AND AXLE ASSEMBLY 131

A-7: SWIVEL TRAVEL PIPING 133

A-8: SWING CIRCLE GREASE TUBE PIPING 135

A-9: INSTALLATION OF LEFT AND RIGHT LADDERS 143

A-10: INSTALLATION OF LEFT CATWALK (STD) 144

A-11: INSTALLATION OF RIGHT CATWALK 145

A-12: INSTALLATION OF CATWALK, HANDRAIL BESIDE OPERATOR’S CAB 146

A-13: INSTALLATION OF OPERATOR’S CAB LADDER 147

A-14: INSTALLATION OF OPERATOR’S CAB HANDRAIL 148

A-16: INSTALLATION OF HANDRAIL AT REAR OF OPERATOR’S CAB 149

A-18: OPERATOR’S CAB FRONT FRAME, HANDRAIL 150

A-20: RIGHT DECK HANDRAIL 151

A-21: INSTALLATION OF LADDER ON TOP OF HYDRAULIC TANK 152

A-22: INSTALLATION OF COUNTERWEIGHT 153

A-23: INSTALLATION OF COUNTERWEIGHT LADDERS (LEFT AND RIGHT) 154

A-24: INSTALLATION OF HANDRAIL ON TOP OF FUEL TANK, COUNTERWEIGHT 155

A-25: INSTALLATION OF FUEL TANK VIBRATION STOPPER BRACKET 156

A-26: INSTALLATION OF GREASE REEL, HOSE, BRACKET 157

A-27: INSTALLATION OF LEFT CAB BASE ASSEMBLY 158

A-28: INSTALLATION OF OPERATOR’S CAB ASSEMBLY 163

A-29: INSTALLATION OF WIPER MOTOR COVER INSIDE OPERATOR’S CAB 164

A-30: INSTALLATION OF UPPER HANDRAIL OF LEFT-HAND DOOR COVER 165

A-31: HANDRAILS ABOVE THE RH DOOR AND ABOVE THE HYDRAULIC OIL TANK 167

A-32: EMERGENCY STOP SWITCH, FUEL CUT LEVER 168

A-33: HANDRAIL ABOVE THE RADIATOR 170

A-34: CONNECTION OF HYDRAULIC PIPING OPERATOR’S CAB ASSEMBLY 171

A-35: CONNECTION OF WINDOW WASHER HOSE OF OPERATOR’S CAB ASSEMBLY 176

A-36: CONNECTION OF AIR PIPING OF LEFT CAB BASE ASSEMBLY 177

A-37: CONNECTION OF GREASE PIPING OF OPERATION’S CAB ASSEMBLY 178

A-38: CONNECTION OF WIRING HARNESS IN CAB BASE 182

A-39: PIPING OF AIR CONDITIONER DISCHARGE HOSE 183

A-40: INSTALLATION OF HEAD GUARD 188

A-41: INSTALLATION OF ORBCOMM ANTENNA 189

A-42: CONNECTION OF BATTERY CABLE 190

A-43: START ENGINE 191

A-44: FINAL TIGHTENING OF SWING CIRCEL MOUNTING BOLTS 199

L-1: INSTALLATION OF LEFT-HAND CATWALK AND POWER-ASSISTED LADDER 200

C INSTALLATION PROCEDURES 203

C-1: INSTALLATION OF BOOM CYLINDRE TO CHASSIS 204

C-2: INSTALLATION OF BOOM CYLINDER PIPING 206

C-3: BLEEDING AIR FROM BOOM CYLINDER 207

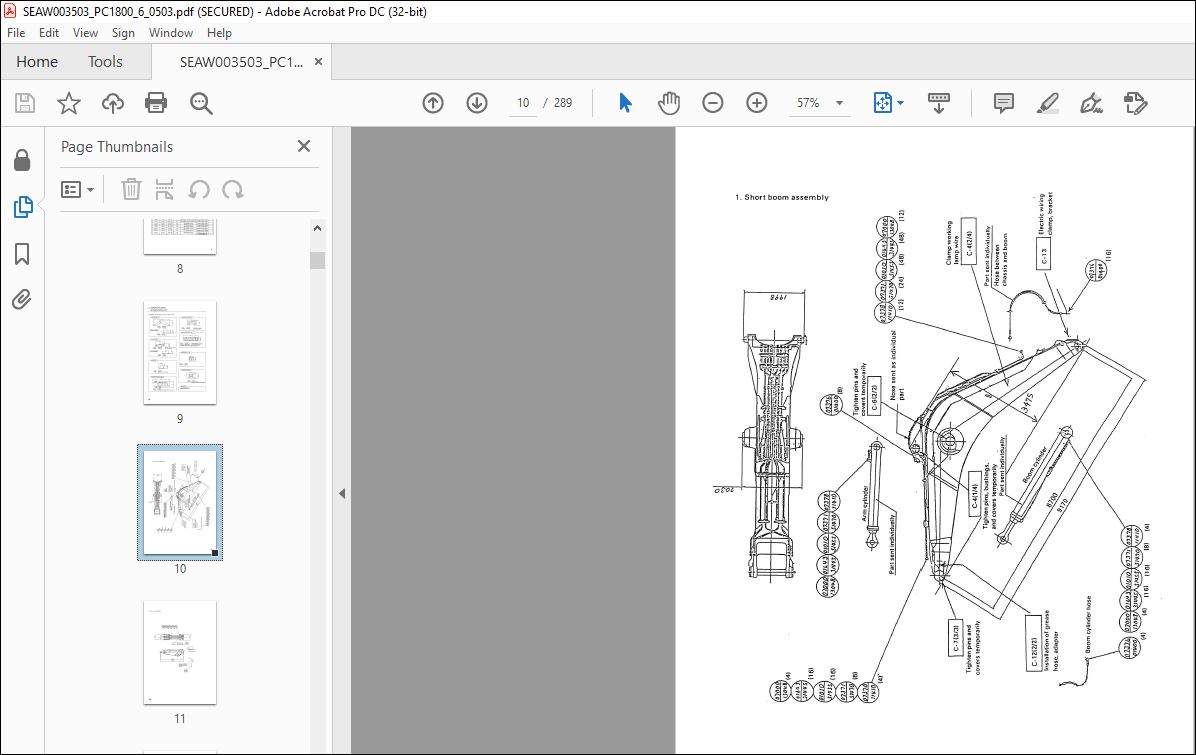

C-4: BOOM SUB-ASSEMBLY 208

C-5: INSTALLATION OF BOOM ASSEMBLY 212

C-6: INSTALLATION OF BOOM CYLINDER TOP PIN 215

C-7: CONNECTION OF ARM ASSEMBLY TO BOOM 217

C-8: INSTALLATION OF HOSES BETWEEN BOOM AND CHASSIS 220

C-9: INSTALLATION OF ARM CYLINDER TOP PIN 222

C-10: BLEEDING AIR FROM ARM CYLINDER 224

C-11: INSTALLATION OF HYDRAULIC HOSES BETWEEN BOOM AND ARM 225

C-12: CONNECTION OF GREASE PIPING 226

C-13: CONNECTION OF WIRING BETWEEN BOOM AND CHASSIS 231

C-14: INSTALLATION OF HOSES BETWEEN BOOM AND CHASSIS 232

C-16: CONNECTION OF BUCKET ASSEMBLY TO ARM 234

C-17: INSTALLATION OF BUCKET LINK 237

C-18: BLEEDING AIR FROM BUCKET CYLINDER 239

M INSPECTION AND SERVICING PROCEDURES 240

M-1: INSPECTING THE OIL LEVEL AND WATER LEVEL 241

M-2: FLUSHING OF HYDRAULIC CIRCUIT 244

M-3: RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT 245

INITIALIZATION PROCEDURES FOR VHMS CONTROLLER 246

SETTING PROCEDURES FOR REPLACING VHMS CONTROLLER 260

FIELD ASSEMBLY INSPECTION REPORT 277

IMAGES PREVIEW OF THE MANUAL:

VIDEO PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the SAME exact manual used by your dealers to fix your vehicle.

- The same can be yours in the next 2-3 mins as you will be directed to the download page immediately after paying for the manual.

- Any queries / doubts regarding your purchase, please feel free to contact [email protected]

I.G