Komatsu Hydraulic Excavator PC750 -7 PC750LC-7 PC750SE-7 PC800 -7 PC800SE-7 Field Assembly Manual – PDF DOWNLOAD

DESCRIPTION:

Komatsu Hydraulic Excavator PC750 -7 PC750LC-7 PC750SE-7 PC800 -7 PC800SE-7 Field Assembly Manual – PDF DOWNLOAD

Foreword

Since this machine is large in size, it is divided into some units to meet the transportation conditions and regulations applied to the transporta tion route when shipped from our factory. This manual describes how to assemble the units into the complete machine in the field. We hope that this machine will display its quality and you will use it safely according to the operation manual. Many units are large in size and heavy in weight and may be handled in a dangerous place or posture and many workers may have to work together to sling them with cranes. Accordingly, before starting the assembly work, the work supervisor is required to hold a safety meeting to oblige the workers to put on pro tective gear and appoint a work leader and a crane work signal man and allot roles to all the workers for safe work. In particular, the above meeting is more important when worker of dif ferent languages and customs work together. The following is a reference supervision system diagram.

TABLE OF CONTENTS:

Komatsu Hydraulic Excavator PC750 -7 PC750LC-7 PC750SE-7 PC800 -7 PC800SE-7 Field Assembly Manual – PDF DOWNLOAD

Specifications

Precautions for Field Assembly

Disposal of Removed Parts

Assembling Procedures Applicable Equipment And schedule

Tightening Torque

Transportation

Packing Style For Transportation

Tightening Torque

Coating Materials List

A Assembling of Chassis

A-1 Installation of Left and Right Track Frames

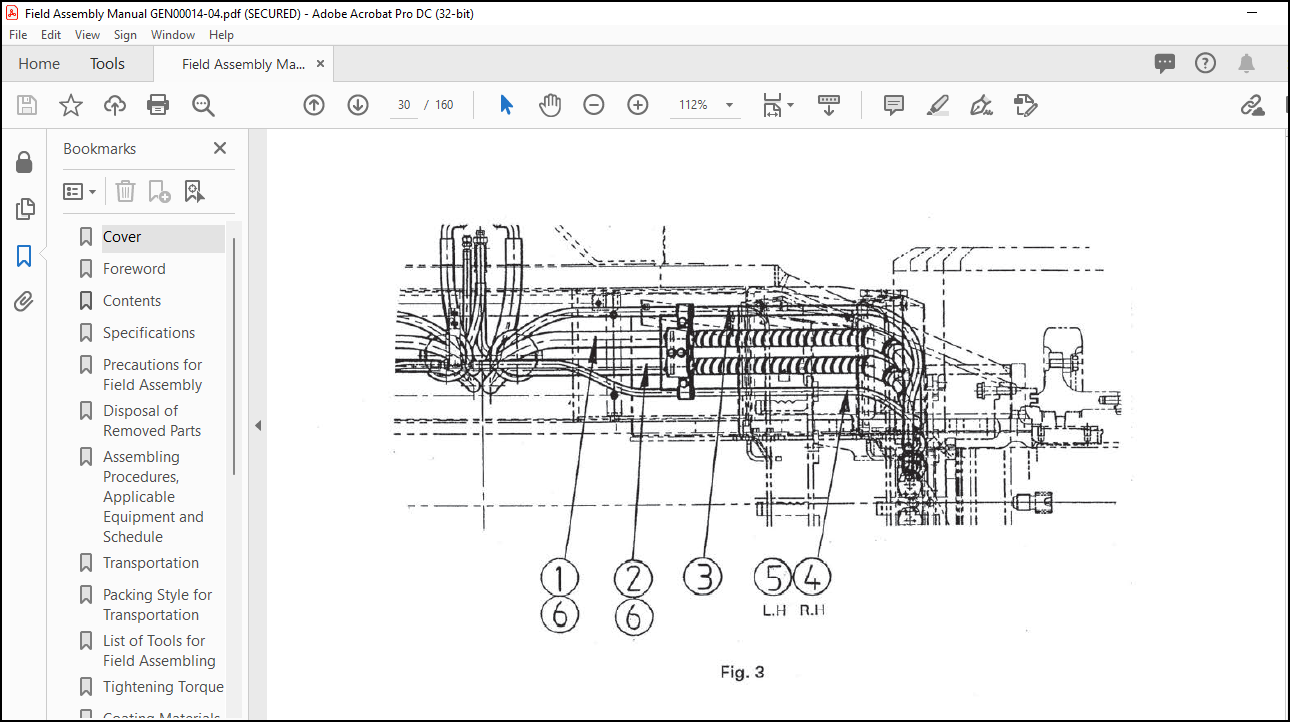

A-2 Installation of Travel Pipe

A-3 Installation of Top Guard

A-4 Installation of Radiator Cover

A-5 lnstallation of Rearview Mirro

A-6 Installation of Handrail

A-7 Installation of Step

A-8 Installation of Left Side Step

A-9 lnstaIIation of Muffler TailTu

A-10 Sticking of Sheet (to Counterweight)

A-11 Installation of Counterweight

A-12 Installation of ORBCOMM Antenna (if equipped )

A-13 Installation of Step Light

A-14 Installation of Travel Pipe Cover

A-15 Extension of Track Frame Gauge (Only when 3-split packages are tansported)

A-16 Testing Track Shoe Tension

A-17 Inspection of Oil Amount and Water Am ount

A-18 Parts to be Touched up After Field Assembly

B Assembling of Work Equipment of Backhoe

B-1 Pulling Out of Boom Foot Pin, and Boom Cylinder Foot Pin

B-2 Installation of Boom Assembly

B-3 Relieving Remaining Pressure

B-4 Installing of Boom Cylinder Foot

B-5 Installing of Boom Cylinder Hose

B-6 Installing of Boom Cylinder

B-7 Installing of Arms Cylinder

B-8 Installing of Arms Cylinder Foot

B-9 Installing of Arams Assembly

B-10 Installing of Hose Between Boom And Bucket Cylinder

B-11 Installing of Bucket Assembly

B-12 Lubrication Piping To Work Equipment

B-13 Connection of Wiring of Work Equipment

B-14 Greasing after Assembling Work Equipment

B-15 Air Bleeding from Hydraulic Cylinder

C Assembling of Work Equipment of Loading Sh ovel

C-1 Releasing residual pressure in hydraulic circuit

c-2 Pulling out boom foot pin and boom cylinder foot pin

C-3 Installation of boom and arm assembly

c-4 Installation of flushing piping between chassis and boom

C-5 Installation of flushing piping for boom cylinder and arm cylinder

C-6 Installation of flushing piping for bucket cylinder

C-7 Installation of flushing piping for bottom dump cylinder

C-8 Installation of boom cylinder …

C-9 Installation of boom cylinder foot

C-10 Installation of boom cylinder hoses

C-11 Installation of boom cylinder rod pi n

C-12 Installation of arm cylinder hoses

C-13 Installation of bucket cyli nde r 圈.... . ...... .

C-14 Installation of bucket cylinder hose

C-15 Installation of connecting hoses between chassis and boom top

C-16 Installation of bottom dump cylinder hoses

C-17 Installation of bucket ass embly

C-18 Installation of working lam ps

C-19 Installation of work equipment grease piping

C-20 Greasing after assembling of work equipment

C-21 Bleeding air from work equipment circuit

Mprocedure For Inspection and Maintence After Completion Of Assemably

M-1 Inspection of oil Level in Hyraulic Track And Refill

M-2 Replacement Of Return Filter (Standard Filter to Flushing Filter)

M-3 Flushing of Hydraulic Circuit

M-4 Replacement of return Filter (Flushing Filter To Standard Filter)

IMAGES PREVIEW OF THE MANUAL:

VIDEO PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the same manual used by the DEALERSHIPS to SERVICE your vehicle.

- The manual can be all yours – Once payment is complete, you will be taken to the download page from where you can download the manual. All in 2-5 minutes time!!

- Need any other service / repair / parts manual, please feel free to contact us at heydownloadss @gmail.com . We may surprise you with a nice offer

S.M