Challenger 2290 2270XD 2270 2260 2250 2240 Large Square Baler CE Operator’s Manual 700746229E – PDF DOWNLOAD

IMAGES PREVIEW OF THE MANUAL:

Challenger 2290 2270XD 2270 2260 2250 2240 Large Square Baler CE Operator’s Manual 700746229E – PDF DOWNLOAD

Challenger 2290 2270XD 2270 2260 2250 2240 Large Square Baler CE Operator’s Manual 700746229E – PDF DOWNLOAD

DESCRIPTION:

Challenger 2290 2270XD 2270 2260 2250 2240 Large Square Baler CE Operator’s Manual 700746229E – PDF DOWNLOAD

A word to the operator :

It is your responsibility to read and understand the safety section in this manual and the manual for all attachments before operating this machine. Remember you are the key to safety. Good safety practices not only protect you, but also the people around you. Study the content in this manual and make the content a working part of your safety program.

- Keep in mind that this safety section is written only for this type of machine. Practice all other usual and customary safe working precautions, and above all remember – safety is your responsibility. You can prevent serious injury or death. This safety section is intended to point out some of the basic safety situations that may be encountered during the normal operation and maintenance of your machine.

- This section also suggests possible ways of dealing with these situations. This section is not a replacement for other safety practices featured in other sections of this manual. Personal injury or death may result if these precautions are not followed. Learn how to operate the machine and how to use the controls properly.

- Do not let anyone operate the machine without instruction and training. For your personal safety and the personal safety of others, follow all safety precautions and instructions found in the manuals and on safety signs affixed to the machine and all attachments. Use only approved attachments and equipment.

This manual:

- This manual covers general safety practices for this machine. The operator manual must always be kept with the machine. Right-hand and left-hand, as used in this manual, are determined by facing the direction the machine will travel when in use.

- The photos, illustrations, and data used in this manual were current at the time of printing, but due to possible in-line production changes, your machine can vary slightly in detail. The manufacturer reserves the right to redesign and change the machine as necessary without notification.

TABLE OF CONTENTS:

Challenger 2290 2270XD 2270 2260 2250 2240 Large Square Baler CE Operator’s Manual 700746229E – PDF DOWNLOAD

1 Safety 13

1 1 Introduction 15

1 1 1 Safety alert symbol 15

1 1 2 Safety messages 15

1 1 3 Informational messages 15

1 1 4 Safety signs 15

1 1 5 A word to the operator 1 6

1 1 6 This manual 1 7

1 1 6 1 Operator manual storage 1 7

1 2 Operation 1 a

1 2 1 General information 18

1 2 2 Prepare for operation 19

1 2 3 Personal protective equipment 19

1 2 4 Seat instructions 20

1 2 5 Shield and guards 20

1 2 6 Exhaust warning 2 1

1 2 7 Flying debris 2 1

1 2 8 Handrails 2 1

1 2 9 Agricultural chemicals 2 1

1 3 Travel on public roads 23

1 4 Maintenance 25

1 4 1 General maintenance information 25

1 4 2 Fire prevention and first aid 2 7

1 4 3 High pressure leaks 28

1 4 4 Accumulator safety 28

1 4 5 Tire safety 29

1 4 6 Replacement parts 29

1 5 Safety and information signs 30

2 Introduction 49

2 1 Introduction 51

2 1 1 Units of measurement 51

2 1 2 Replacement parts 51

2 1 3 Intended use 51

2 1 4 Proper disposal of waste 51

2 2 Machine identification 52

2 2 1 Serial number plate location 52

2 2 2 Serial number description 53

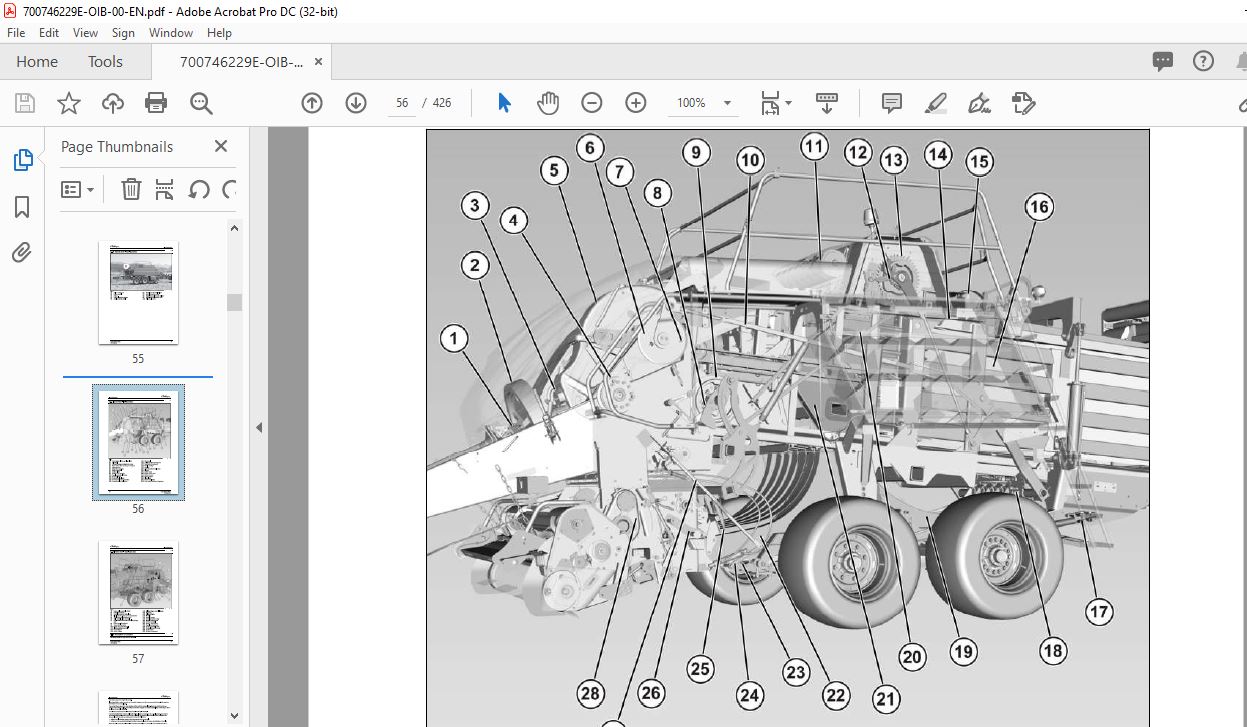

2 3 Machine components 54

2 3 1 Outside view – left-hand side 54

2 3 2 Outside view – right-hand side 55

2 3 3 Inside view – left-hand side 56

2 3 4 Inside view – right-hand side 57

2 3 5 Description of operation 57

2 4 Kn otters 59

2 4 1 Double knotter system 59

2 4 2 Knotter operation 59

2 5 EC declaration of conformity 63

3 Operation 65

Large Square Baler

700746229E

Table of contents

3 1 Checklists 69

3 1 1 Daily checklist 6 9

3 1 2 Inspection after the first hour of operation 6 9

3 2 High quality hay 70

3 2 1 Crop preparation 7 0

3 2 2 Crop moisture 7 0

3 2 3 High quality hay baling 7 1

3 2 4 Dry hay bale storage 7 1

3 2 5 High moisture silage bales 7 1

3 2 6 Silage baling 7 2

3 2 6 1 XD baler load 7 2

3 2 7 Silage bale storage 7 2

3 3 Brakes and locks 73

3 3 1 Flywheel brake 7 3

3 3 2 Knotter/needle lockout 7 3

3 3 2 1 Locking the knotter/needle lockout 7 4

3 3 2 2 Unlocking the knotter/needle lockout 7 4

3 3 3 Stuffer latch 75

3 4 Connecting to the tractor 76

3 4 1 Removing the shipping bracket 7 6

3 4 2 Hitch component identification 7 6

3 4 3 Baler height setting 7 7

3 4 4 Tractor setup dimensions with an 8 0 mm (3 15 in) ball hitch, a CE spherical ball

hitch, or a 5 0 mm ( 2 in) ring hitch 7 7

3 4 5 Tractor setup dimensions with a 4 0 mm (1 6 in) high ring hitch 7 8

3 4 6 Installing the machine hitch 7 8

3 4 7 Connecting the machine hitch to the tractor drawbar 8 0

3 4 8 Connecting a 5 0 mm ( 2 in) ring hitch to the tractor 8 0

3 4 9 Connecting an 8 0 mm (3 15 in) ball hitch to the tractor 8 1

3 4 10 Connecting a 4 0 mm (1 6 in) high ring hitch to the tractor 8 1

3 4 1 1 Operating a hydraulic tongue jack 8 2

3 4 1 2 Installing the safety transport chain 8 2

3 4 13 Constant velocity implement driveline, if equipped 8 3

3 4 13 1 Connecting a quick disconnect yoke to a power take off 8 3

3 4 13 2 Making marks on the constant velocity implement driveline 8 4

3 4 13 3 Checking the constant velocity implement driveline angle 8 4

3 4 13 4 Adjusting the constant velocity implement driveline angle 85

3 4 13 5 Checking the constant velocity implement driveline clearance 85

3 4 14 Equal angle implement driveline, if equipped 8 6

3 4 14 1 Connecting a quick disconnect yoke to a power take-off 8 6

3 4 14 2 Adjusting the angles of an equal angle implement driveline 8 7

3 5 Electrical, hydraulic, and brake connections 89

3 5 1 Connecting the road lamp harness plug 89

3 5 2 Connecting the control harness plug 89

3 5 3 Connecting the four pin plug, machines with a disconnect brake 89

3 5 4 Connecting the machine hydraulic hoses to the tractor 9 0

3 5 5 Connecting the machine hydraulic brake hoses to the tractor 9 1

3 5 6 Connecting the machine air brake hoses to the tractor 9 1

3 6 Baler operation 92

3 6 1 Preparing to bale 9 2

3 6 2 Starting the baler 9 2

3 6 2 1 The plunger is away from the bale 9 2

3 6 2 2 The plunger is near or on the bale 9 2

3 6 2 3 Baler fails to start 9 2

3 6 3 Baling the first bale 9 3

3 6 4 Baling 9 4

3 6 5 Stopping the baler 9 4

Large Square Baler

700746229E

Table of contents

3 6 6 Stuffer cycle 95

3 7 Electronics 9 6

3 7 1 General terminal information 96

3 7 2 Terminal harness information 96

3 7 3 Terminal screen trees 96

3 7 4 Icon functions 99

3 7 5 Startup screen 1 0 6

3 7 6 Main work screens 10 7

3 7 6 1 Changing the main work screen boxes 108

3 7 6 2 Main work screen boxes 108

3 7 6 3 Operating directional arrows 1 1 2

3 7 6 4 Flakes per bale 1 1 3

3 7 6 5 Bale density cylinder pressure 1 1 3

3 7 6 6 Changing between automatic and manual control mode 1 15

3 7 6 7 Plunger load 1 16

3 7 6 8 Plunger load setting information 1 17

3 7 6 9 Setting the plunger load 1 18

3 7 6 10 Feeder slip 1 19

3 7 6 1 1 Main work screen display area 1 2 0

3 7 7 Accumulator (if equipped) 1 2 2

3 7 7 1 Accumulator bale position 1 2 2

3 7 7 2 Accumulator modes 1 2 2

3 7 7 3 Accumulator manual mode operation 1 2 3

3 7 7 4 Accumulator bale unload indication 1 2 3

3 7 7 5 Accumulator errors 1 2 3

3 7 7 6 Accumulator shift lockout setting 1 24

3 7 8 Scale, if equipped 1 25

3 7 8 1 Bale weight 1 25

3 7 9 Strokes per flake 1 26

3 7 10 Releasing the bale chamber pressure before ejecting a bale 1 26

3 7 1 1 Releasing the bale chamber pressure 1 27

3 7 1 2 Machine settings screen 1 28

3 7 1 2 1 Machine settings screen information 1 28

3 7 1 2 2 Chain lubrication 1 28

3 7 1 2 3 Manual chain lubrication start 13 0

3 7 1 2 4 Setting the knotter lubrication interval 13 0

3 7 1 2 5 Setting the knotter lubrication operating time 13 0

3 7 1 2 6 Manual knotter lubrication start 13 1

3 7 1 2 7 Manual knotter lubrication stop 13 1

3 7 1 2 8 Setting the moisture alarm, if equipped 13 1

3 7 1 2 9 Changing the bale length 13 1

3 7 1 2 10 Changing the crop type 13 2

3 7 1 2 1 1 Changing the audio settings 13 2

3 7 1 3 Service screen 13 3

3 7 13 1 Service screen display 13 3

3 7 13 2 Switch service screen 13 4

3 7 13 3 Voltage service screen 13 4

3 7 13 4 Frequency service screen 1 3 5

3 7 14 Alarm log screen 1 3 5

3 7 14 1 Alarm detail screen 13 6

3 7 14 2 Removing an alarm 13 6

3 7 15 Machine configuration screen 13 7

3 7 16 Calibrating the accumulator scale 13 7

3 7 17 Calibrating the bale length, if equipped 1 3 9

3 7 18 Calibrating the roller bale chute scale with an object of a known weight 14 1

3 7 19 Calibrating the roller bale chute scale with a test bale 14 3

3 7 2 0 Calibrating the cutter 14 4

3 7 2 1 Work records screen 145

Large Square Baler

700746229E

Table of contents

3 7 2 1 1 Job record screen 14 6

3 7 2 1 2 Changing the current job 148

3 7 2 1 3 Customer record screen 148

3 7 2 1 4 Changing the current customer 149

3 7 2 1 5 Year record screen 15 0

3 7 2 1 6 Changing the current year 15 1

3 7 2 1 7 Clearing a record 15 1

3 7 2 1 8 Storing work records on a data card 15 2

3 7 2 1 9 Lifetime counter screen 15 2

3 7 2 2 Indicator icons and error number 15 3

3 7 2 2 1 Machine indicator icons and error numbers 15 3

3 7 2 2 2 Accumulator indicator icons and error numbers 15 4

3 7 2 2 3 Scale indicator icons and error numbers 155

3 7 2 3 Alarms 155

3 7 2 3 1 Alarm information 155

3 7 2 3 2 Visual alarm descriptions 155

3 7 2 3 3 Audible alarm descriptions 155

3 7 2 3 4 Alarm table 15 6

3 8 Pickup and windguard 166

3 8 1 Pickup height 16 6

3 8 2 Adjusting the pickup wheels 16 6

3 8 3 Adjusting the pickup height 16 7

3 8 4 Adjusting the pickup flotation 16 7

3 8 5 Windguard height 16 8

3 9 Knotter and needles 169

3 9 1 Monitoring flags 16 9

3 9 2 Missing knots 17 0

3 10 Changing the bale length 171

3 11 Rotor cutter – early production cutter 172

3 1 1 1 Knife engaging and disengaging 17 2

3 1 1 2 Changing the cut length 17 2

3 12 Rotor cutter – late production cutter 174

3 1 2 1 Changing the cutter knife setting 175

3 1 2 2 Lowering the cutterbed 17 7

3 1 2 3 Raising the cutterbed 17 8

3 1 2 4 Removing debris from the cutter knives 18 0

3 1 2 5 Unplugging the cutter 18 3

3 13 Cutter/packer 185

3 13 1 Changing the cut length 185

3 1 3 2 Unplugging the cutter 185

3 14 Roller bale chute, if equipped 187

3 14 1 Lowering the roller bale chute 18 7

3 14 2 Raising the roller bale chute 18 7

3 15 Lighting and reflectors 189

3 16 Tandem axle steering lock 190

3 17 Preparing to road the machine or to move the machine on a trailer 191

3 18 Lifting and tie down 194

3 18 1 Lifting a baler correctly 19 4

3 18 2 Lifting points 19 4

3 18 3 Tie down points 195

3 19 Threading a four twine baler 197

3 19 1 Installing twine balls 19 7

3 19 2 Threading the left-hand needle twine box 19 7

3 19 3 Threading the right-hand needle twine box 198

3 19 4 Threading the needle twine box tensioners 2 0 0

3 19 4 1 Needle twine tensioners 2 0 1

Large Square Baler

700746229E

Table of contents

3 19 5 Threading the needle twines into the needle twine area 2 0 1

3 19 6 Threading the needle slacker arms 2 0 2

3 19 7 Threading the twines to the needles 2 0 2

3 19 8 Threading the twine hooks for needles 2 0 3

3 19 9 Threading the left-hand knotter twine box 2 0 4

3 19 10 Threading the right-hand knotter twine box 2 05

3 19 1 1 Threading the twines into the knotter area 2 0 6

3 19 1 2 Threading the twines through the knotters 2 0 7

3 19 1 3 Threading and tying the needle and the knotter twines 2 0 8

3 20 Threading a six twine baler 21 o

3 2 0 1 Installing twine balls 2 10

3 2 0 2 Threading the left-hand needle twine box 2 10

3 2 0 3 Threading the right-hand needle twine box 2 1 2

3 2 0 4 Threading the needle twine box tensioners 2 1 3

3 2 0 4 1 Needle twine tensioners 2 14

3 2 0 5 Threading the needle twines into the needle twine area 2 14

3 2 0 6 Threading the needle slacker arms 2 15

3 2 0 7 Threading the twines to the needles 2 16

3 2 0 8 Threading the twine hooks for needles 2 17

3 2 0 9 Threading the left-hand knotter twine box 2 17

3 2 0 10 Threading the right-hand knotter twine box 2 19

3 2 0 1 1 Threading the twines into the knotter area 2 2 0

3 2 0 1 2 Threading the twines through the knotters 2 2 1

3 2 0 13 Threading and tying the needle and the knotter twines 2 2 2

3 21 Removing a bale from the bale chamber 224

3 2 1 1 Operating the ejector, if equipped 2 24

3 2 1 2 Removing a bale from the bale chamber – no ejector 2 25

3 2 1 3 Removing high moisture bales 2 26

3 22 Air brake pressure release 227

3 23 Disconnecting the tractor 22a

4 Maintenance 231

4 1 Service schedule 235

4 2 General maintenance information 239

4 2 1 Maintenance safety 2 3 9

4 2 2 Lowering the front step 2 3 9

4 2 3 Raising the front step 2 3 9

4 2 4 Ladder and handrails 24 0

4 2 5 Step ladder 24 0

4 2 6 Sealed bearings 24 0

4 2 7 Electrical system general information 24 0

4 2 8 Hydraulic system general information 24 1

4 2 9 Jack points 24 1

4 3 Lubrication points 242

4 3 1 Driveline lubrication and maintenance 24 2

4 3 1 1 Removing and installing the implement driveline shields 24 3

4 3 2 Lubricating the hitch ball, if equipped 24 4

4 3 3 Lubricating the main drive slip clutch 24 4

4 3 4 Lubricating the overrunning clutch 245

4 3 5 Lubricating the flywheel bearing 245

4 3 6 Lubricating the connecting rods 245

4 3 7 Lubricating the packer crank bearings 246

4 3 8 Inspecting the packer crank bearings 24 7

4 3 9 Lubricating the packer/cutter crank bearings 24 7

4 3 10 Inspecting the packer/cutter crank bearings 24 7

4 3 1 1 Lubricating the cutter rotor clutch, if equipped 248

4 3 1 2 Lubricating the anchor for the rotor cutter chain tensioner 248

Large Square Baler

700746229E

Table of contents

4 3 1 3 Lubricating the rotor cutter bearings 249

4 3 14 Lubricating the knife cranks, if equipped 249

4 3 15 Lubricating the main drive sprocket 2 50

4 3 16 Lubricating the stuffer drive 2 50

4 3 17 Lubricating the knotter/needle clutch 251

4 3 18 Lubricating the brake linkage 251

4 3 19 Lubricating the tandem axle pivot bushings 252

4 3 2 0 Lubricating the metering wheel shaft 252

4 3 2 1 Lubricating the six twine knotter center fitting 252

4 3 2 2 Lubricating the tucker arm and twine arm cam rollers 2 53

4 3 2 3 Lubricating the bale density cylinders 2 53

4 3 24 Lubricating the packer clutch 2 54

4 3 2 5 Lubricating the main packer/cutter crank bearing 2 54

4 3 26 Lubricating the packer/cutter chain tensioner 2 54

4 3 2 7 Lubricating the pickup overrunning clutch 2 55

4 3 28 Lubricating the pickup linkage roller 2 55

4 3 29 Lubricating the pickup spring pivot 2 55

4 4 Main Gearbox 256

4 4 1 Checking the main gearbox oil 2 56

4 4 2 Changing the main gearbox oil 2 56

4 5 Rotor cutter gearbox, if equipped 258

4 5 1 Checking the rotor cutter gearbox oil 2 58

4 5 2 Changing the rotor cutter gearbox oil 2 58

4 6 Hydraulic system 259

4 6 1 Checking the hydraulic oil level 2 59

4 6 2 Adding hydraulic oil 2 59

4 6 3 Changing the hydraulic oil and filter 2 59

4 7 Shearbolts 261

4 7 1 Replacing the flywheel shearbolt 26 1

4 7 2 Replacing the stuffer/knotter shearbolt 26 2

4 8 Knotter lubrication pump 264

4 8 1 Priming the knotter lubrication lines 26 4

4 9 Chain lubrication pump, if equipped 266

4 10 Flywheel brake 267

4 10 1 Checking the flywheel brake adjustment 26 7

4 10 2 Adjusting the flywheel brake 26 7

4 11 Slip clutches 269

4 1 1 1 Main drive slip clutch adjustment 26 9

4 1 1 2 Packer slip clutch adjustment 26 9

4 1 1 3 Pickup slip clutch adjustment 2 7 0

4 1 1 4 Checking the pickup slip clutch – GHB0 x10 1 and later 2 7 0

4 1 1 5 Adjusting the pickup slip clutch – GHB0 x10 1 and later 2 7 0

4 1 1 6 Rotor cutter slip clutch adjustment, if equipped 2 7 1

4 12 Drive chains 272

4 1 2 1 Roller chain maintenance 2 7 2

4 1 2 2 Lubricating the packer chain 2 7 2

4 1 2 3 Lubricating the rotor cutter chain 2 7 3

4 1 2 4 Lubricating the stuffer/knotter/needle chain 2 7 3

4 1 2 5 Lubricating the right-hand pickup chains 2 7 3

4 1 2 6 Lubricating the left-hand pickup chains 2 7 4

4 1 2 7 Adjusting the packer chain 2 7 4

4 1 2 8 Adjusting the packer/cutter chain 2 7 4

4 1 2 9 Adjusting the support rails 2 7 5

4 1 2 10 Adjusting the rotor cutter chain, if equipped 2 7 5

4 1 2 1 1 Adjusting the stuffer/knotter/needle chain 2 7 5

4 1 2 1 2 Adjusting the right-hand pickup chains 2 7 6

Large Square Baler

700746229E

Table of contents

4 1 2 13 Adjusting the left-hand pickup chains 2 7 6

4 13 Timing the baler 278

4 14 Rotor cutter – early production cutter 279

4 14 1 Replacing the knives 2 7 9

4 14 2 Sharpening the knives 28 1

4 14 3 Filler plate location 28 2

4 15 Rotor cutter – late production cutter 28 4

4 15 1 Replacing the knives 28 4

4 15 2 Sharpening the knives 28 6

4 15 3 Replacing the rotor blades 28 7

4 16 Stuffer 288

4 16 1 Adjusting the stuffer sensor door 288

4 16 2 Adjusting the stuffer clutch 289

4 16 3 Adjusting the stuffer brake 29 0

4 16 4 Stuffer chute adjustment 29 2

4 16 5 Unplugging the stuffer chute 29 2

4 17 Plunger 29 4

4 17 1 Plunger inspection 29 4

4 17 2 Adjusting the plunger knives 29 4

4 17 3 Inspecting the top and side hay dogs 295

4 17 4 Inspecting the stationary hay dogs 295

4 18 Knotter system maintenance 296

4 18 1 Parts holding magnet 29 6

4 18 2 Twine tension 29 6

4 18 3 Billhook and billhook cam 29 7

4 18 4 Adjusting the billhook and billhook cam 298

4 18 5 Replacing a billhook 298

4 18 6 Replacing the twine knife 299

4 18 7 Adjusting the stripper arm 3 0 0

4 18 8 Twine disc operation 3 0 1

4 18 9 Timing the twine disc 3 0 2

4 18 10 Adjusting the twine holder 3 0 3

4 18 1 1 Knotter service parts 3 0 3

4 19 Needle maintenance 30 4

4 19 1 Installing a needle 3 0 4

4 19 2 Centering a needle 3 0 4

4 19 3 Needle actuating rod length 3 05

4 19 4 Checking needle penetration 3 05

4 19 5 Adjusting needle penetration – all needles 3 05

4 19 6 Adjusting needle penetration – one needle 3 0 6

4 19 7 Adjusting the needle roller height 3 0 6

4 19 8 Adjusting the needle lateral load 3 0 7

4 19 9 Adjusting the twine fingers 3 08

4 19 10 Adjusting the tucker arms 3 09

4 19 1 1 Adjusting the knotter/needle brake 3 10

4 19 1 2 Inspecting the knotter/needle inner cam lobe 3 1 2

4 19 1 3 Adjusting the reset roller and outer cam lobe 3 1 2

4 20 Adjusting the needle protection linkage 31 4

4 21 Sensors and switches locations and specifications 316

4 22 Tires, wheels, and axles 318

4 2 2 1 Tire pressure 3 18

4 2 2 2 Wheel hardware 3 18

4 2 2 3 Inspect the wheel bearings for too much movement 3 18

4 2 2 4 Removing the wheel bearings – single axle without brakes 3 19

4 2 2 5 Remove the wheel bearings – machines with brakes 3 19

4 2 2 6 Inspecting the wheel bearing 3 2 0

Large Square Baler

700746229E

Table of contents

4 2 2 7 I n sta l l i n g t h e wheel bea r i n g s – s i n g l e axle without b ra kes 32 1

4 2 2 8 I n sta l l the wheel bea ri n g s – s i n g l e axle with b ra kes a n d a l l ta n d e m axles 32 1

4 2 2 9 Axl e ha rdwa re 323

4 23 Brakes 3 2 5

4 23 1 I n s pection p roced u re for b ra kes 3 2 5

4 2 3 2 I n s pect t h e bra ke l i n i n g th i c kn e s s 3 2 5

4 2 3 3 R e p l a c e t h e b ra ke l i n i n g s 3 2 6

4 2 3 4 Adj ust t h e b ra kes 3 2 8

4 2 3 5 R u bber b ra ke w i p e r 3 2 8

4 2 3 6 I n s pect t h e park b ra ke syste m 3 2 8

4 2 3 7 I n s pect t h e a i r b ra ke system 3 2 9

4 2 3 8 C l ea n i n g t h e a i r b ra ke fi lter 3 2 9

4 2 3 9 I n s pecti n g the hyd ra u l i c b ra ke syste m 3 2 9

4 2 3 1 0 B l eed i n g t h e hyd ra u l i c b ra ke system 330

4 24 Preparing for storage 33 1

4 25 Preparing for a new season 332

5 Troubleshooting 333

5 1 Shearbolt troubleshooting 335

5 2 Main drive train troubleshooting 338

5 3 Main gearbox troubleshooting 339

5 4 Feed system troubleshooting 340

5 5 Stuffer troubleshooting 342

5 6 Knotter/needle clutch troubleshooting 343

5 7 Tying troubleshooting 344

5 8 Needle troubleshooting 352

5 9 Bale length troubleshooting 353

5 10 Bale shape troubleshooting 355

5 11 Knotter blower troubleshooting, if equipped 356

5 12 Knotter lubrication system troubleshooting 357

5 13 Hydraulic troubleshooting 358

5 14 Alarm troubleshooting 3 6 1

5 15 Ejector troubleshooting, if equipped 363

5 16 Brake troubleshooting, if equipped 364

5 17 Electronic troubleshooting 365

6 Specification 367

6 1 Specifications 369

6 1 1 D i m e n s i o n s and weig hts 369

6 1 2 D rive syste m specificati o n s 370

6 1 3 S h ea rbolt s pecificat i o n s 37 1

6 1 4 Hyd ra u l i c s pecificat i o n s – on board 372

6 1 5 P i c k u p s pecificat i o n s 372

6 1 6 R otor cutte r specificat i o n s – early p roduction 373

6 1 7 Rotor cutte r specificati o n s – late p ro d u ction 37 4

6 1 8 Packer specificati o n s 3 7 5

6 1 9 Packer/c utter specificati o n , if eq u i pped 3 7 5

6 1 1 0 Stuffer specificati o n s 3 7 5

6 1 1 1 P l u n g e r s pecificat i o n s 3 7 6

6 1 1 2 Twi n e s pecificat i o n s 3 7 6

6 1 1 3 Kn otte r a n d need l e s pecificat i o n s 377

6 1 1 4 Bale c h a m be r te n s i o n s pecificat i o n s 377

6 1 1 5 Ejector s pecificat i o n s 377

6 1 1 6 Roller ba l e ch ute specificati o n s , if eq u i pped 378

Large Square Baler

700746229E

Table of contents

6 1 1 7 La m p s pecification 378

6 1 1 8 Kn otte r l u b rication p u m p specificati o n s 378

6 1 1 9 C h a i n l u b rication p u m p s pecifications, if eq u i pped 379

6 1 2 0 L u b rica nts and capacities 379

6 1 2 1 T i re specificati o n s 380

6 1 2 2 B ra ke s pecificat i o n s , if eq u i pped 3 8 1

6 1 2 3 Maxi m u m s p e e d 383

6 1 24 Tractor req u i re m e nts 383

6 1 2 5 N o i s e l eve l s 384

7 Accessories 385

7 1 Accessories 387

7 1 1 I m p l e m e n t d rive l i n e ( I D L) 387

7 1 2 Hyd ra u l i c jack kit 387

7 1 3 C 1 000 Te rm i n a l kit 387

7 1 4 AG CO M MAN D™ te l e m etry kit 388

7 1 5 B a l e ejector 388

7 1 6 B a l e ch ute 388

7 1 7 R o l l e r ba l e ch ute 389

7 1 8 B a l e we i g h t kit 389

7 1 9 E l ectro n i c knotte r trip kit 389

7 1 1 0 C h a i n l u b rication kit 389

7 1 1 1 B eacon kit 390

7 1 1 2 R o l l e r w i n d g u a rd 390

7 1 1 3 R e m ova b l e p i c k u p w h e e l s 390

7 1 1 4 Hay res i stor p lates 390

7 1 1 5 Accu m u lator m o u n t i n g kit 391

7 1 1 6 Bale acc u m u lator 391

7 1 1 7 Bale we i g h t kit for a n accu m u l ator 391

7 1 1 8 Powe r a d a pter p l u g 391

7 1 1 9 Deca l re p l aceme nts 392

7 1 20 S h e a rbolts and lock n uts 392

7 1 2 1 S e rvice pa rts kits 392

7 1 2 2 ASAB E type ba l l h itch 392

7 1 2 3 Ba l l h itch b u s h i n g 392

7 1 24 ISO type h itches 392

8 Assem bly 395

8 1 Assem bly 397

8 1 1 C h ecki n g the m a c h i n e before a s s e m b ly 397

8 1 2 M a c h i n e a s s e m b l y 397

8 1 2 1 Asse m b l i n g the p i c k u p 397

8 1 2 2 R a i s i n g the h a n d ra i l s 398

8 1 2 3 I n sta l l i n g t h e m o n itori n g flags 401

8 1 2 4 I n sta l l i n g a beaco n , if e q u i pped 402

8 1 2 5 I n sta l l i n g the rea r l a m p ba rs 404

8 1 2 6 S peed deca l , if req u i red 405

8 1 2 7 I n sta l l i n g t h e i m p l e m e n t d rive l i n e ( I D L) 405

8 1 2 8 I n sta l l i n g an opti o n a l con sta nt velocity d rive l i n e 407

8 1 3 Asse m b l i n g the ta n d e m axle, if eq u i pped 4 1 1

8 1 4 Con n ecti n g the tractor 4 1 1

8 1 5 M a c h i n e d i s co n n ect b ra ke h a rness i n sta l l ation 4 1 2

8 1 5 1 H a rness a n d switc h e s 4 1 2

8 1 5 2 I n sta l l i n g t h e powe r co n n ector a n d t h e switch e s 4 1 2

8 1 5 3 Co n n ecti n g the co n n ectors 4 1 3

8 1 5 4 Locat i n g the fo u r p i n co n n ector 4 1 3

8 1 6 C h ecki n g t h e knotte r l u b rication syste m 4 1 3

8 1 7 C h ecki n g t h e f i n a l a dj u stme nts 4 1 4

Large Square Baler

700746229E

Table of contents

8 2 Checklists 4 1 5

8 2 1 Pre-delivery checklist 4 15

8 2 2 Delivery checklist 4 15

9 Index 4 1 7

Large Square Baler

700746229E

VIDEO PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the SAME exact manual used by your dealers to fix your vehicle.

- The same can be yours in the next 2-3 mins as you will be directed to the download page immediately after paying for the manual.

- Any queries / doubts regarding your purchase, please feel free to contact [email protected]

S.V