Case IH Tractor OPTUM 250,270,300 CVX CVXDrive STAGE V Operator’s Manual

FILE DETAILS:

Case IH Tractor OPTUM 250,270,300 CVX CVXDrive – STAGE V Operator’s Manual_51607610

Size : 35.7 MB

Format : PDF

Language : English

Number of Pages : 646 pages

Brand: Case IH

Type of machine: Tractor

Type of document: Operator’s Manual

Model: OPTUM 250,270,300 CVX

Part No: 51607610

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Case IH Tractor OPTUM 250,270,300 CVX CVXDrive – STAGE V Operator’s Manual_51607610

- General information This manual has been prepared according to ISO 3600:1996 to assist you in the correct procedure for running- in, driving and operating and for the maintenance of your new tractor. Read this manual carefully. Your tractor is intended for use in normal and customary agricultural applications. If at any time you require advice concerning your tractor, do not hesitate to contact your authorised dealer. He has factory trained personnel, genuine manufacturers’ parts and the necessary equipment to carry out all your service requirements. The specification are provided for your information and guidance. For further information concerning your tractor and equipment, consult your authorised dealer. All data given in this manual is subject to production variations. Dimensions and weight are approximate only. The illustrations do not necessarily show tractors in standard condition or imply that these features are available in all countries. For exact information about any particular tractor, please consult your authorised dealer.

- Your tractor has been designed and built to give maximum performance, economy and ease of operation under a wide variety of operating conditions. Your tractor fulfills all requirements as specified in the Regulation (EU) No 167/2013 of the European Parliament and of the Council. Prior to delivery, the tractor was carefully inspected, both at the factory and by your dealer to ensure that it reaches you in optimum condition. To maintain this condition and ensure trouble- free operation, it is important that the routine services, as specified on page 7-12 of this Manual, are carried out at the recommended intervals. All persons training to operate, or who will operate this tractor should be old enough to possess a valid local vehicle operating permit (or meet other applicable local age requirements). These persons must demonstrate the ability to operate and service the tractor in correct and safe manner.

- About this manual This manual gives information for use of your machine, as intended and under the conditions foreseen by the manufacturer during normal operation and routine service and maintenance. Read and understand; keep it in good condition and always safely store it in the provided pocket in the back of your seat for later easy retrieval. This manual does not contain all the information related to periodical service, converting and repairs to be carried out by professional service personnel. The Table of Contents page(s) are provided to have an overview of main manual’s topics. A detailed alphabetic index is available at the end of this manual for locating specific items.

Normal operation means the use of the tractor for the purpose intended by the manufacturer by an operator familiar with the tractor and the mounted or towed equipment and complying with the information for operation and safe practices, as specified by the manufacturer in this manual and by the decals on the tractor and the equipment.

- Normal operation includes the preparation and storage of the tractor, swinging components into work position and vice versa, adding or removing ballast and picking up and setting off attachments.

- Normal operation includes the adjustment and setting of the tractor and equipment, for the specific condition of the field and/ or the crop. Routine service

- Routine service and maintenance means activities that must be done daily by an operator familiar with the tractor characteristics and complying with the information for routine service and safe practices, as specified by the manufacturer in this manual and by decals on the tractor, in order to maintain its proper function. Routine service includes activities such as fueling, cleaning, washing, topping up fluid levels, greasing, replacing of consumable articles such as lamp bulbs. Converting, periodical service and repair

- Periodical service means activities that must be done at defined intervals by trained personnel familiar with the tractor characteristics and which are complying with the information for periodical service and safe practices, as partly specified by the manufacturer in this manual and in other Company literature, in order to maintain the expected life time of the tractor.

- Converting means activities that must be done by professional service personnel familiar with the tractor characteristics and complying with the information for converting, as partly specified by the manufacturer in this manual, in assembly instructions or in other Company literature, in order to fit the tractor to a specific configuration.

- Repair means activities that must be done by professional service personnel only familiar with the tractor characteristics and complying with the information for repair, as specified by the manufacturer in the dealer’s workshop manual, in order to restore the proper function of the tractor after a failure or degradation of performance.

TABLE OF CONTENTS:

Case IH Tractor OPTUM 250,270,300 CVX CVXDrive – STAGE V Operator’s Manual_51607610

1 GENERAL INFORMATION

Metric and imperial units abbreviations 1-1

To the owner 1-3

Operator’s manual storage1-5

Product identification1-6

Engine identification 1-7

Drive line identification 1-8

Cab identification 1-9

Product identification plate 1-10

Programming tractor functions 1-11

Before operating the tractor 1-12

International symbols 1-13

Machine stability1-14

Selective Catalytic Reduction (SCR) system 1-18

Selective Catalytic Reduction (SCR) system 1-25

2 SAFETY INFORMATION

Safety precautions 2-1

Safety decals 2-3

Safety rules2-12

Burn prevention 2-19

Prevention of fire or explosions2-20

Fire extinguisher2-21

Protection offered by the tractor2-22

Hazardous substances2-25

Ecology and the environment 2-26

Emergency exit 2-27

Wheel chocks2-28

Intended use statement 2-29

Instructor’s seat 2-31

3 CONTROLS AND INSTRUMENTS

ACCESS TO OPERATOR’S PLATFORM

Introduction3-1

Cab air filters 3-5

In cab storage (where fitted)3-6

Cable and wiring routing 3-7

Mobile telephone usage 3-8

Implement monitor installation 3-9

OPERATOR’S SEAT

Operator’s seat 3-10

Air suspension seat deluxe 3-11

Air suspension seat with passive or Dynamic Damping System (DDS)3-16

Air suspension seat ‘evolution active’ 3-22

Seat belt 3-29

INSTRUCTOR’S SEAT

Instructional seat 3-30

FORWARD CONTROLS

Ignition key 3-30

Hazard lights switch 3-31

Lights and turn indicator lever 3-32

Windshield wiper and washer controls 3-33

Electronic parking brake3-34

Emergency brake 3-37

Anti-lock braking system ABS Operation 3-38

Clutch pedal 3-45

Foot brakes 3-45

Exhaust brake (where fitted) 3-49

Steering column3-49

RIGHT-HAND SIDE CONTROLS

Integrated control panel 3-50

Multifunction Handle 3-51

REARWARD CONTROLS

Switches on C-pillar 3-52

Battery isolator switch (where fitted)3-53

Heated screens (where fitted) 3-54

ISO bus functionality 3-55

Hydraulic master switch 3-56

Switches on right-hand trim3-57

Advanced steering system field/road switch 3-58

Variable Ratio Steering (VRS) 3-59

Autoguidance system3-62

Autoguidance – Variable ratio steering 3-63

Variable ratio steering and Autoguidance symbols on color display (where fitted) 3-64

OVERHEAD CONTROLS

Switches on roof 3-65

Left-hand and right-hand outermost work light switch3-66

Interior light 3-67

Automatic Temperature Control (ATC) 3-68

INSTRUMENT CLUSTER

Integrated control unit3-70

Gauges3-70

Indicator and warning lights3-71

Displays 3-74

Keypad enhanced 3-75

Selecting or changing the display settings3-77

Adjust menu 3-78

Configure menu3-83

Active and Manual Catalyst Management3-85

Manual Catalyst Management3-87

Performance monitor 3-93

Tire Pressure Monitoring System (TPMS) (where fitted) 3-99

Armrest color display3-102

Pop-up screens on color display3-105

Performance monitor on color display3-110

Programming the displays3-115

Alarm functions3-118

Accessing stored error codes3-120

Selective Catalytic Reduction (SCR) exhaust treatment – Overview3-121

Warning and advisory symbols 3-130

Warning and advisory symbols 3-146

4 OPERATING INSTRUCTIONS

COMMISSIONING THE UNIT

Refueling the tractor4-1

STARTING THE UNIT

Starting the engine 4-3

Grid heater cold start aid (where fitted) 4-5

Fuel heater (where fitted)4-5

Coolant immersion heater (where fitted)4-6

Transmission oil heater (where fitted)4-7

STOPPING THE UNIT

Stopping the engine4-8

Automatic engine shut down4-9

MOVING THE UNIT

Operating in cold temperatures 4-11

Low idle speed management 4-14

Variable Pitch Fan (VPF)4-15

5 TRANSPORT OPERATIONS

PREPARING FOR ROAD TRANSPORT

Carrying the tractor on a transporter 5-1

Secure the high visibility roof panel 5-1

RECOVERY TRANSPORT

Freeing a stuck tractor5-2

Towing the tractor 5-3

6 WORKING OPERATIONS

GENERAL INFORMATION

Constant engine speed6-1

Differential lock 6-4

Four wheel drive6-6

Front axle suspension (where fitted) 6-8

HTS standard 6-11

Headland turn sequence – Quick guide6-11

Recording and replaying6-13

Explanation of symbols 6-16

Recording a sequence 6-18

Replaying a sequence 6-20

HTS advanced6-24

Headland turn sequence6-24

Universal symbols 6-25

Recording a sequence 6-28

Creating a sequence in standstill 6-33

Replaying a sequence 6-35

Saving a sequence6-39

Edit a sequence6-42

Recalling a sequence6-46

Deleting a sequence 6-50

Headland turn sequence error codes 6-51

HTS advanced with Automatic End Of Row Turn functionality6-54

Automatic End Of Row Turn functionality 6-54

Implement setup 6-56

Creating field boundaries and headlands 6-57

Recording a sequence 6-61

Replaying a sequence 6-65

TRANSMISSION

Transmission operation6-69

Anti jack knife 6-70

Stationary control 6-71

Engine speed control6-72

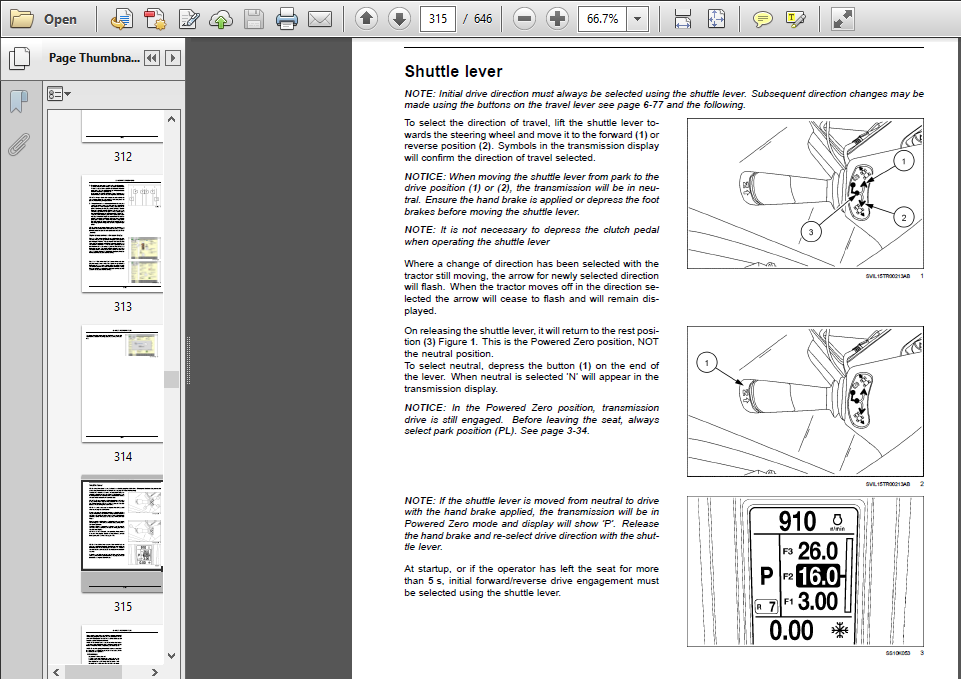

Shuttle lever6-75

Transmission controls 6-77

Drive pedal 6-80

Programming maximum speed 6-81

Transmission display6-83

Manual mode 6-84

Automatic mode 6-85

Speed matching 6-86

Pneumatic Trailer Brake Stabilization System 6-87

Fault codes 6-89

REAR POWER TAKE-OFF (PTO)

Power Take-Off (PTO) operating precautions 6-90

Changing the PTO output shaft 6-90

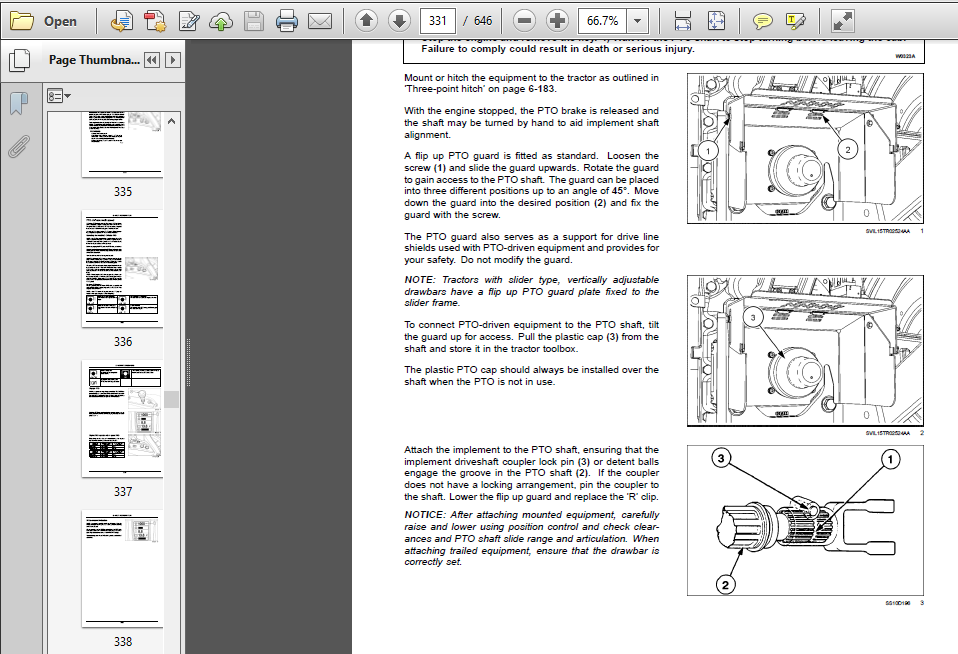

Attaching PTO driven equipment6-91

PTO operation 6-92

PTO shiftable multi speed 6-96

External PTO controls 6-99

Auto PTO operation6-101

FRONT POWER TAKE OFF

PTO operation6-104

Auto PTO operation6-109

External PTO controls 6-111

REAR HITCH

Electronic Draft Control (EDC) 6-113

Settings and adjustments6-117

Electronic Draft Control (EDC) operation 6-119

External hitch controls 6-125

FRONT HITCH

Settings and adjustments6-127

Front hitch operation 6-130

External hitch controls 6-133

Front hitch management 6-134

Auxiliary front couplers (where fitted)6-140

External controls for front couplers 6-142

ELECTRO-HYDRAULIC REMOTE CONTROL VALVES (where fitted)

Remote control valves6-143

Settings and adjustments6-151

Valve priority 6-157

Programming tractor functions 6-159

Connecting remote cylinders6-166

Operating with remote valves 6-169

Mid mount remote valves6-171

External EHR controls 6-173

EHR implement control setting 6-174

Transmission rear axle and hydraulic system oil level 6-178

HYDRAULIC POWER BEYOND PORT

Power beyond circuit 6-180

ISO Power beyond couplings 6-182

THREE POINT HITCH

Attaching three-point hitch equipment 6-183

Lift rod adjustment 6-185

Top link adjustment 6-188

Quick hitch6-190

Automatic stabilizers (where fitted)6-192

Hydraulic stabilizers (where fitted)6-194

DRAWBARS AND TOWING ATTACHMENTS

Drawbars and towing attachments6-196

Swinging drawbar 6-200

Automatic pickup hitch6-202

Rear trailer hitches 6-207

TRAILER BRAKING SYSTEMS

Trailer brake release switch 6-214

Air-operated trailer brakes (Universal type)6-215

Air-operated trailer brakes (UK type) 6-218

Air-operated trailer brakes (Italian type) 6-219

Auxiliary air supply connector (where fitted) 6-220

Hydraulic trailer brakes (Universal type – Dual line) 6-221

Hydraulic trailer brakes (Universal type – Single line) 6-224

Hydraulic trailer brakes (Italian type) 6-225

WHEEL TRACK ADJUSTMENT

Tire combinations 6-226

Front wheel track adjustment 6-228

Front wheel alignment 6-231

Steering stops6-232

Front axle oscillation stops 6-233

Front wheel fenders6-234

Rear wheel track adjustment 6-236

Flange type axle (where fitted) 6-236

Bar type axle (where fitted) 6-238

Dual rear wheels (where fitted) 6-241

BALLASTING AND TIRES

Ballasting and tires 6-243

Iron weights (where fitted)6-246

Liquid ballast 6-249

Tire inflation 6-251

Tire pressures and permissible loads6-252

AUXILIARY POWER CONNECTIONS

Diagnostic socket 6-254

Trailer electrical socket6-255

Electrical power connectors6-256

Internal power connectors6-256

External power connectors 6-258

ISO bus classes 6-260

ISO bus functionality 6-262

Reconfigurable inputs for ISO Bus function6-270

7 MAINTENANCE

GENERAL INFORMATION

Introduction7-1

Fuel requirement – Diesel fuel 7-2

Fuel – Storage, handling and transport 7-2

Biodiesel fuel 7-3

Engine oils7-5

Protective devices 7-6

Tractor jacking points 7-8

General specifications 7-9

Capacities7-10

Organic Acid Technology (OAT) coolant 7-11

MAINTENANCE CHART

Maintenance chart7-12

WHEN THE WARNING LAMP LIGHTS

Change the engine air cleaner outer element7-14

Drain the fuel system water separator 7-15

Check the brake fluid level 7-16

EVERY 10 HOURS OR EACH DAY

Check the engine coolant level7-17

Check the engine oil level 7-18

Check the remote control valve drain bottles7-18

Check windscreen washer reservoir7-19

Drain air reservoir on air operated trailer brake 7-19

FIRST 50 HOURS

Service operations7-20

EVERY 50 HOURS

Clean the cab air filter7-21

Clean the SCR cover air ducts7-23

Clean the cooler section7-24

Grease all fittings 7-25

Check the front and the rear wheel nuts 7-31

Check the tire pressures and the tire condition 7-31

EVERY 150 HOURS

Inspect the compressor drive belt7-32

EVERY 375 HOURS

Inspect the poly V-belt 7-33

Check the battery fluid level7-33

Check the transmission oil level, the rear axle oil level and the hydraulic oil level 7-35

EVERY 750 HOURS

Change engine oil and filter7-36

Change the first stage fuel filter and the fuel filter element 7-38

Change the hydraulic charge pump oil filter and the van pump oil filter7-40

Check the engine air intake connections 7-41

Check the transmission oil cooler pipe couplings 7-42

Check the 4WD front axle differential oil level and the hubs oil level7-43

EVERY 750 HOURS OR EVERY YEAR

Change the engine air cleaner outer element7-44

EVERY 750 HOURS OR EVERY 2 YEARS

Change the 4WD planetary hub oil 7-44

EVERY YEAR

Check the accumulators (where fitted) 7-45

EVERY 1500 HOURS OR EVERY YEAR

Change the cab air filters7-45

EVERY 1500 HOURS OR EVERY 2 YEARS

Change the engine air cleaner inner element7-47

Change the air brake drier reservoir7-48

Change the transmission oil, the rear axle oil and the hydraulic oil 7-49

Clean the lubrication pump filter 7-50

Change the engine breather filter7-51

Change the Diesel Exhaust Fluid (DEF)/AdBlue® suction filter7-52

Change the hydraulic suction pump oil filter 7-53

Change the 4WD differential oil 7-54

EVERY 2 YEARS

Change the air conditioning receiver drier7-55

EVERY 1500 HOURS OR EVERY 4 YEARS

Change the poly V-belts 7-56

EVERY 2250 HOURS

Check the engine tappet valve clearance 7-58

EVERY 3750 HOURS OR EVERY 3 YEARS

Change the DEF/AdBlue® main filter 7-58

EVERY 3750 HOURS OR EVERY 4 YEARS

Change the engine coolant fluid 7-59

GENERAL MAINTENANCE

Cleaning the tractor 7-62

Check first stage fuel filter and water trap 7-65

Bleeding the fuel system7-65

Hydraulic system hoses 7-66

Electrical socket maintenance7-67

Check the brake pedal latching/unlatching7-68

Adjust the cab suspension (where fitted) 7-69

Adjust the automatic pickup hitch7-70

Headlight adjustment 7-71

Work light adjustment7-71

Bulb replacement 7-72

Fuses and relays 7-74

Protecting the electronic and electrical systems during battery charging or welding 7-85

Battery removal and installation 7-86

STORAGE

Tractor storage7-88

Removing the machine from storage 7-88

8 TROUBLESHOOTING

FAULT CODE RESOLUTION

Introduction 8-1

ALARM(S)

Fault codes and symbols 8-2

SYMPTOM(S)

Engine8-4

Transmission 8-5

Hydraulics 8-5

Three-point hitch 8-6

Brakes8-6

Cab8-6

Electrical system 8-7

9 SPECIFICATIONS

General dimensions 9-1

Minimum turn radius9-3

Axle dimension9-4

Maximum operating angle 9-6

Maximum permissible operating weights 9-7

Tractor weights9-7

Capacities 9-8

Engine9-9

Fuel system9-9

Air cleaner system 9-10

Cooling system 9-10

Transmission 9-10

Rear Power Take-Off (PTO) 9-11

Front Power Take-Off (PTO)9-11

Hydraulic system9-12

Rear three-point hitch 9-12

Front three-point hitch 9-13

Remote control valves9-14

Front remote control valve 9-14

Brakes 9-15

Steering9-15

Electrical equipment9-16

Minimum hardware tightening torques 9-17

10 ACCESSORIES

Radio (where fitted)10-1

External rear view mirrors10-1

Border marker plates 10-3

Auxiliary head lights and signature lights 10-4

Rotating beacon 10-4

Auxiliary pneumatic coupler 10-5

11 FORMS AND DECLARATIONS

Service record 1st 50 hour, Owner copy11-1

Service record 1st 50 hour, Dealer copy11-3

Telematics module declaration of conformity 11-4

PLEASE NOTE:

- This is the SAME MANUAL used by the dealerships to diagnose your vehicle

- No waiting for couriers / posts as this is a PDF manual and you can download it within 2 minutes time once you make the payment.

- Your payment is all safe and the delivery of the manual is INSTANT – You will be taken to the DOWNLOAD PAGE.

- So have no hesitations whatsoever and write to us about any queries you may have : heydownloadss @gmail.com