Case IH Magnum 225 250 280 310 335 Tractors Operators Manual

DESCRIPTION:

- This manual contains important information about the safe operation, adjustment and routine maintenance of your Magnum series tractor. The manual is divided into ten chapters as outlined in the table of contents. Refer to the index at the end of this manual for locating specific items about your tractor. Do NOT operate or permit anyone to operate or service this machine until you or the other persons have read this manual. Use only trained operators who have demonstrated the ability to operate and service this machine correctly and safely.

- This Operator’s Manual is to be stored in the manual compartment equipped on this machine. Make sure this manual is in good condition. Contact your dealer to obtain additional manuals. Contact your dealer for any further information or assistance about your machine. Your dealer has approved service parts. Your dealer has technicians with special training that know the best methods of repair and maintenance for your tractor. 1 –

IMAGES:

VIDEO PREVIEW:

TABLE OF CONTENTS:

1 GENERAL INFORMATION

Personal safety 1-1

Product identification1-3

Note to the Owner 1-4

Tractor intended use1-5

Manual storage 1-5

Declaration of conformity 1-6

Product identification1-7

Component location 1-9

2 SAFETY INFORMATION

Safety rules 2-2

ROPS and CSF2-6

SAFETY DECALS 2-8

3 CONTROLS/INSTRUMENTS

ACCESS TO OPERATOR’S PLATFORM

Tractor access 3-1

OPERATOR’S SEAT

Overview 3-2

Control identification 3-4

INSTRUCTOR’S SEAT

Overview 3-7

FORWARD CONTROLS

STEERING COLUMN3-9

FRONT CONSOLE3-12

PEDAL CONTROLS3-14

LH SIDE CONTROLS

EMERGENCY BRAKE3-17

RH SIDE CONTROLS

ARMREST CONSOLE3-18

ARMREST COMPARTMENT3-26

Adjusting the armrest console3-29

REARWARD CONTROLS

FENDER CONSOLE3-31

AUTOMATIC TEMPERATURE CONTROLS 3-37

AUTOMATIC TEMPERATURE CONTROL SYSTEM3-40

VENTILATION3-41

OVERHEAD CONTROLS

LAMPS3-43

EXTERIOR CONTROLS

REAR FENDER3-45

INSTRUMENT CLUSTER

Overview3-46

GAUGES3-47

DEDICATED DISPLAY3-49

KEYPAD 3-51

STATUS AND WARNING ICONS 3-54

PROGRAMMABLE DISPLAY3-56

DISPLAY SETTINGS3-76

OPERATOR PREFERENCES 3-86

ICON LEGEND 3-96

4 OPERATING INSTRUCTIONS

COMMISSIONING THE UNIT

Before starting the engine4-1

STARTING THE UNIT

NORMAL ENGINE STARTING4-5

Cold temperature operation 4-8

STOPPING THE UNIT

STOPPING THE ENGINE4-11

MOVING THE UNIT

Powershift transmission 4-12

Transmission default gears 4-13

Setting default gears4-17

Best practices for prolonged transmission life4-20

Transmission disengages; neutral icon flashes 4-21

Automatic productivity management (APM)4-22

Mechanical front drive (MFD)4-31

Differential lock system4-35

Suspended axle4-38

Ride control4-46

Constant engine speed4-49

Electronic end of row system 4-51

5 TRANSPORT OPERATIONS

ROAD TRANSPORT

Tractor warning lamps5-2

Tractor warning lamps5-3

Safe transport speed 5-4

SHIPPING TRANSPORT

Securing the tractor for shipping5-5

RECOVERY TRANSPORT

Safety rules 5-6

TOWING THE TRACTOR5-7

6 WORKING OPERATIONS

GENERAL INFORMATION

Overview 6-1

REAR PTO

Safety rules6-3

Connecting the PTO6-7

Interchangeable PTO shaft6-8

Reversible PTO shaft6-14

PTO operation6-16

PTO fender switch operation6-20

Auto PTO operation 6-21

THREE POINT HITCH

Identification6-26

Link adjustment 6-27

Hitch high clearance adjustment6-31

Hydraulic links6-34

Sway limiter adjustment6-35

Lower link block adjustment6-36

Mechanical float adjustment6-38

Hitch operation6-39

Hitch remote switch operation 6-45

Position control operation6-46

Load control operation 6-48

Slip control operation6-50

Hitch set point6-53

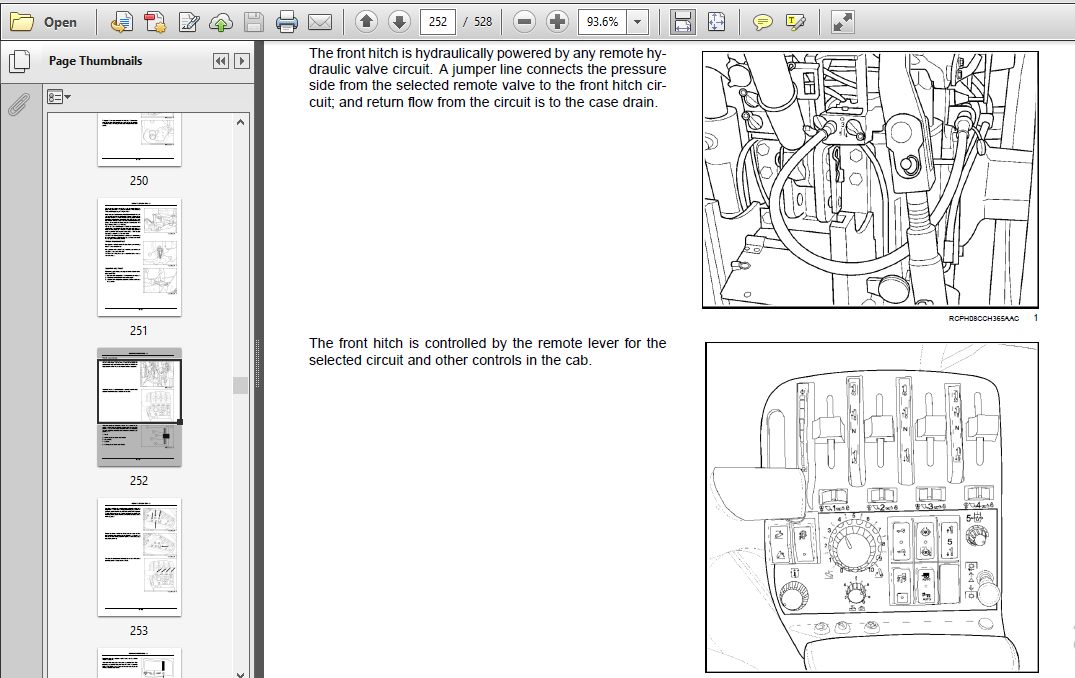

FRONT HITCH

Overview 6-56

Hitch operation6-58

DRAWBARS AND TOWING ATTACHMENTS

Drawbar capacity/position6-62

Adjusting the drawbar6-64

TRAILER HITCHES

Clevis and special drawbars6-66

Automatic trailer hitch6-68

Auto pickup hitch operation6-71

Manual trailer hitch6-73

AUXILIARY POWER CONNECTIONS

Auxiliary power and lighting6-76

Cab power connections6-78

HYDRAULIC REMOTE CONTROL VALVES

Valve couplers and connections 6-80

Motor return circuit6-83

Power beyond circuit6-84

Overview 6-86

Operating the controls6-87

Changing the functional mode6-90

Remote hydraulic auto mode6-94

Auto depth control 6-97

BALLASTING THE TRACTOR

Guidelines 6-101

Tire load and inflation charts 6-105

Weights, cast metal and liquid 6-106

Wheel slip and power hop performance6-113

MECHANICAL FRONT DRIVE (MFD) AXLES

Tire combinations and tread positions6-117

Steering and oscillation stops6-122

REAR AXLE

Rear wheel installation6-125

Rear wheel tread settings 6-127

Rear wheel tread settings 6-142

7 MAINTENANCE

GENERAL INFORMATION

Safety rules 7-1

Opening the hood 7-2

Battery access and service7-4

Tire and rim service7-5

Tractor jacking points 7-7

Capacities7-9

Consumables 7-11

Electrical component location7-15

Electrical system specification 7-19

Maintenance chart notes7-20

MAINTENANCE CHART

Maintenance Chart7-20

At warning message display

Air filter service icon/message 7-22

First 10 to 50 hours

Differential and planetary oil7-23

Wheel bolt torque7-24

Weight bolt torque7-25

Every 10 hours or daily

Engine oil level 7-26

Transmission oil level 7-27

Engine coolant level 7-28

Engine auxiliary fuel filter7-29

Air tank – Drain fluid 7-30

Rear hitch and front axle7-31

Every 50 hours

Engine primary fuel filter7-32

Every 300 hours

Battery water level (Note E)7-33

Engine air intake hoses 7-34

Engine coolant level – deaeration tank7-35

Engine oil and filter7-36

Wheel bolt torque7-38

Weight bolt torque7-39

Front axle (Note A)7-40

Rear hitch (Note A)7-47

Fuel tank7-49

Differential and planetary oil level (Note B)7-50

Transmission oil pressure oil pressure7-52

Reversible 1000 RPM PTO shaft (Note D) 7-54

Every 600 hours

Engine coolant antifreeze protection7-55

Engine coolant filter 7-56

Engine coolant hoses and clamps7-57

Engine primary fuel filter7-58

Changeable PTO internal splines 7-60

Every 1200 hours or annually

Differential and planetary oil7-61

Engine air filters7-65

Engine air precleaner 7-69

Every 1500 hours

Transmission oil7-70

Transmission oil filter7-72

Regulated transmission filter 7-73

Every 2100 hours

Engine coolant 7-74

Fuel injector nozzles (Note C)7-77

Engine valve adjustment (Note C)7-77

Every 3000 hours

Engine vibration damper (Note C)7-78

Emergency steering system7-79

As required

Vehicle fire prevention 7-81

Vehicle fire prevention 7-82

Cab air filter7-83

Engine primary air filter7-86

Grille screen and radiator area 7-89

Fuel tank vent filter7-91

Transmission clutch and accumulator 7-91

Tire pressure 7-91

Fan belt7-92

Spark arresting muffler7-93

Remote valve collection bottle 7-94

Emergency brake lever7-95

Engine auxiliary fuel filter7-96

Cab fabric and carpet 7-98

Seat belt 7-99

STORAGE

TRACTOR STORAGE7-100

REMOVAL FROM STORAGE7-100

ELECTRICAL SYSTEM

Radio or audio system 7-101

Battery removal and installation7-102

Auxiliary battery connections7-104

Head light – Replace 7-105

Flood and work light7-111

Fender tail light and warning light7-113

Roof front warning and work light7-115

Roof rear warning light 7-118

High intensity work light7-120

Side turn indicator light 7-122

Rotating beacon light 7-124

Number plate light7-125

Interior light – Replace7-126

8 TROUBLESHOOTING

ALARM(S)

Display warnings 8-1

9 SPECIFICATIONS

ENGINE – General specification9-2

POWER TRAIN – General specification9-4

POWER TRAIN – General specification9-7

TRAVELLING – Speeds 9-10

Vehicle dimensions and shipping weight9-19

Maximum operating weight9-21

10 ACCESSORIES

Front wheel fenders10-1

Farming system displays10-7

Chemical tank mounting 10-10

Loader connection and operation 10-12

Trailer brake connections10-13

General accessories

FILE DETAILS:

LANGUAGE:ENGLISH

PAGES:528

FILE TYPPE:PDF

DOWNLOADABLE:YES

PLEASE NOTE:

⦁ This is the same manual used by the dealers to diagnose and troubleshoot your vehicle

⦁ You will be directed to the download page as soon as the purchase is completed. The whole payment and downloading process will take anywhere between 2-5 minutes

⦁ Need any other service / repair / parts manual, please feel free to contact [email protected] . We still have 50,000 manuals unlisted