Buell Xb12r Firebolt 2008 Factory Service Repair Manual

FILE DETAILS:

LANGUAGE:ENGLISH

PAGES:700+

DOWNLOADABLE:YES

FILE TYPE:PDF

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Buell Xb12r Firebolt 2008 Factory Service Repair Manual

GENERAL

This Service Manual has been prepared with two purposes in mind. First, it will acquaint the user with the construction of the Buell product and assist in the performance of basic maintenance

and repair. Secondly, it will introduce to the professional Buell Technician the latest field-tested and factory-approved major repair methods. We sincerely believe that this Service Manual will make your association with Buell products more pleasant and profitable.

HOW TO USE YOUR SERVICE MANUAL

Refer to the table below for the content layout of this manual.

NO. CHAPTER

1 Maintenance

2 Chassis

3 Engine

4 Fuel System

5 Electric Starter

6 Drive/Transmission

7 Electrical

A Appendix A Connector Repair

B Appendix B Wiring

C Appendix C Conversions

D Appendix D Hose and Wire Routing

E Appendix E Active Intake (Japanese Models)

F Appendix F Glossary

Use the TABLE OF CONTENTS (which follows this FOREWORD) and the INDEX (at the back of this manual) to quickly locate subjects. Sections and topics in this manual are sequentially numbered for easy navigation.

Bearings Anti-friction bearings must be handled in a special way. To keep out dirt and abrasives, cover the bearings as soon as they are removed from the package. Wash bearings in a non-flammable cleaning solution. Knock out packed lubricant inside by tapping the bearing against a wooden block.Wash bearings again. Cover bearings with clean material after setting them down to dry. Never use compressed air to dry bearings.

- Coat bearings with clean oil. Wrap bearings in clean paper. When bearings are installed against shoulders, be sure that the chamfered side of the bearing always faces the shoulder. Lubricate bearings and all metal contact surfaces before pressing into place.

- Only apply pressure on the part of the bearing that makes direct contact with the mating part. Install bearings with numbered side facing out. Always use the proper tools and fixtures for removing and installing bearings. Bearings do not usually need to be removed.

- Only remove bearings if necessary. Bushings Do not remove a bushing unless damaged, excessively worn or loose in its bore. Press out bushings that must be replaced. When pressing or driving bushings, be sure to apply pressure in line with the bushing bore.

- Use a bearing/bushing driver or a bar with a smooth, flat end. Never use a hammer to drive bushings. Inspect the bushing and the mated part for oil holes. Be sure all oil holes are properly aligned.

TABLE OF CONTENTS:

Buell Xb12r Firebolt 2008 Factory Service Repair Manual

GENERAL

Servicing a New Motorcycle

Safe Operating Maintenance

Shop Practices

Repair Notes

Safety

Removing Parts

Cleaning

Disassembly and Assembly

Checking Torques on Fasteners with Lock Patches

Magnetic Parts Trays

Repair and Replacement Procedures

Hardware and Threaded Parts

Threadlocking Agents

Wiring, Hoses and Lines

Instruments and Gauges

Bearings

Bushings

Gaskets

Lip Type Seals

O Rings (Preformed Packings)

Gears

Shafts

Part Replacement

Exhaust System Leakage

Cleaning

Part Protection

Cleaning Process

Rust or Corrosion Removal

Bearings

Tool Safety

Air Tools

Wrenches

Pliers/Cutters/Pry bars

Hammers 4

Punches/Chisels 4

Screwdrivers 4

Ratchets and Handles 4

Sockets 4

Storage Units 4

FUEL AND OIL

Fuel 5

Gasoline Blends: Buell Models 5

Engine Lubrication 5

Winter Lubrication 6

MAINTENANCE SCHEDULE

General 7

4 BATTERY MAINTENANCE

General 9

Battery Disconnection and Removal 0

Cleaning and Inspection 0

Charging Battery 0

Safety Precautions 0

Using a Battery Charger 0

Battery Installation and Connection

Storage

5 ENGINE OIL AND FILTER

General

Engine Oil Level Check

Change Engine Oil and Filter

Drain Oil

Change Filter 4

Fill Engine With Oil 4

Clear Oil Cooler 4

Return to Service 5

6 BRAKE SYSTEM MAINTENANCE

General 6

Bleeding Brakes 6

Bleeding Front Brake 7

Bleeding Rear Brake 8

Brake Pedal Adjustment 8

Brake Pad Thickness 9

Brake Rotor Thickness 0

Brake Pad Replacement 0

Front Pad Removal 0

Front Pad Installation 0

Rear Pad Removal

Rear Pad Installation

7 TIRES AND WHEELS

Tire Inflation

Tire Wear

Wheel Bearings 4

8 CLUTCH/TRANSMISSION/PRIMARY

FLUID

Inspection 5

Transmission Fluid 5

Adjustment 6

9 DRIVE BELT MAINTENANCE

General 8

Inspection 8

Rear Sprocket 8

Drive Belt 8

Idler Pulley 8

Cleaning 8

0 PRIMARY CHAIN

Inspection

Adjustment

STEERING HEAD BEARINGS

General

Inspection

Determining Proper Resistance

SPARK PLUGS

Inspection

AIR CLEANER AND EXHAUST SYSTEM

Removal 5

Cleaning and Inspection 6

Installation 6

Exhaust System Leak Check 7

4 THROTTLE CABLE

Throttle Cable Adjustment 8

5 INTERACTIVE EXHAUST CABLE

Adjustment 9

III

TABLE OF CONTENTS

6 HEADLIGHT

Inspection 4

Adjustment: Firebolt 4

Adjustment: Lightning 4

Horizontal Alignment 4

Vertical Alignment 4

Adjustment: Ulysses/Lightning XB STT 4

Horizontal Alignment 4

Vertical Alignment 4

7 WINDSHIELD MAINTENANCE

General 44

8 STORAGE

General 45

Removal From Storage 45

9 TROUBLESHOOTING

General 46

Engine 46

Starter Motor Does Not Operate or Does Not Turn Engine

Over 46

Engine Turns Over But Does Not Start 46

Starts Hard 46

Starts But Runs Irregularly or Misses 46

Spark Plug Fouls Repeatedly 46

Pre Ignition or Detonation (Knocks or Pings) 47

Overheating 47

Valve Train Noise 47

Excessive Vibration 47

Check Engine Light Illuminates During Operation 47

Lubrication System 47

Oil Does Not Return To Oil Tank 47

Engine Uses Too Much Oil Or Smokes Excessively 47

Engine Leaks Oil From Cases, Push Rods, Hoses,

Etc 47

Low Oil Pressure 47

High Oil Pressure 47

Electrical System 48

Alternator Does Not Charge 48

Alternator Charge Rate Is Below Normal 48

Speedometer Operates Erratically 48

Transmission 48

Shifts Hard 48

Jumps Out Of Gear 48

Clutch Slips 48

Clutch Drags Or Does Not Release 48

Clutch Chatters 48

Clutch 48

Slips 48

Drags or Does Not Release 48

Chatters 48

Chassis 48

Irregular/Inadequate Brake Action 48

Handling Irregularities 48

Suspension 49

CHASSIS

SPECIFICATIONS

Firebolt

Lightning

Ulysses

VEHICLE IDENTIFICATION NUMBER

(V I N )

Vehicle Identification Number (V I N )

WHEELS

General 5

Troubleshooting 5

4 FRONT WHEEL

Removal 7

Disassembly 7

Bearing Removal 7

Front Rotor Removal 9

Cleaning and Inspection 9

Assembly 0

Bearing Installation 0

Front Rotor Installation

Installation

5 REAR WHEEL

Removal 5

Cleaning and Inspection 5

Disassembly 5

Assembly 7

Installation 7

6 TIRES

General 9

Specifications 9

Removal 0

Cleaning and Inspection

Installation

Checking Tire Lateral Runout

Checking Tire Radial Runout

Adjustment

Wheel Balancing

7 CHECKING CAST RIM RUNOUT

General 4

Rim Lateral Runout 4

Rim Radial Runout 4

8 FRONT BRAKE MASTER CYLINDER

AND HAND LEVER

Removal 5

Disassembly 5

Brake Hand Lever 5

Front Master Cylinder 6

Cleaning and Inspection 6

Assembly 6

Front Master Cylinder 6

Brake Hand Lever 6

Installation 7

9 FRONT BRAKE LINE

Removal 8

Installation 8

IV TABLE OF CONTENTS

TABLE OF CONTENTS

0 FRONT BRAKE CALIPER

Removal 0

Disassembly 0

Cleaning and Inspection 0

Assembly

Installation

BRAKE PEDAL

Removal

Installation

REAR BRAKE MASTER CYLINDER

Removal: Firebolt/Lightning 4

Removal: Ulysses 5

Disassembly 7

Cleaning and Inspection 7

Assembly 7

Installation: Firebolt/Lightning 8

Installation: Ulysses 8

REAR BRAKE LINE

Removal: Firebolt 40

Installation: Firebolt 40

Removal: Lightning 4

Installation: Lightning 4

Removal: Ulysses 4

Installation: Ulysses 4

4 REAR BRAKE CALIPER

Removal 45

Disassembly 45

Cleaning and Inspection 46

Assembly 46

Installation 46

5 FENDERS

Front Fender: XB R 48

Removal 48

Installation 48

Rear Fender: XB R 48

Removal 48

Installation 48

Front Fender: XB9SX/XB S/XB Scg 48

Removal 48

Installation 48

Rear Fender: XB9SX/XB S/XB Scg 48

Removal 48

Installation 48

Front Fender: XB STT 48

Removal 48

Installation 48

Rear Fender: XB Ss/XB STT/XB X 49

Removal 49

Installation 49

Front Fender: XB X 49

Removal Upper Front Fender 49

Removal Lower Front Fender 49

Installing Upper Front Fender 49

Installing Lower Front Fender 49

6 FRONT FORK: ALL MODELS EXCEPT

XB STT/XB X

General 50

Removal 50

Disassembly 5

Damper Rod Disassembly 5

Cleaning and Inspection 55

Assembly 55

Damper Rod Assembly 55

Fork Assembly 55

Installation 57

7 FRONT FORK: XB STT/XB X

General 58

Removal 58

Disassembly 58

Cleaning and Inspection 6

Assembly 6

Installation 64

8 FORK CLAMPS: UPPER AND LOWER

Removal Firebolt 65

Installation: Firebolt 65

Removal: Lightning/Ulysses 66

Installation: Lightning/Ulysses 66

9 STEERING HEAD BEARINGS

Removal 68

Installation 68

0 FRONT FORK SLIDER PROTECTORS:

XB STT

Replacement: XB STT 7

SWINGARM AND BRACE

General 7

Brace 7

Removal 7

Installation 7

Removal: Swingarm 7

Disassembly 7

Swingarm 7

Cleaning and Inspection 7

Assembly 74

Swingarm 74

Installation: Swingarm 74

FRONT AND REAR ISOLATORS

Front Isolator 76

Removal 76

Installation 76

Rear Isolator 76

FRAME PUCKS

Removal 77

Installation 77

4 FRAME

Removal 78

Installation 78

TABLE OF CONTENTS V

TABLE OF CONTENTS

5 REAR SHOCK ABSORBER

General 79

Removal: Firebolt 8

Removal: Lightning 8

Removal: Ulysses 8

Installation: Firebolt 8

Installation: Lightning 8

Installation: Ulysses 84

6 THROTTLE CONTROL

Removal and Disassembly 85

Cleaning and Inspection 86

Assembly and Installation 86

Throttle Cable Replacement 86

Removal 86

Installation 86

7 CLUTCH CONTROL

General 88

Removal and Disassembly 88

Clutch Cable 88

Assembly and Installation 9

Clutch Cable 9

8 HEADLAMP ASSEMBLY AND

SUPPORT BRACKET

Removal: Firebolt 9

Disassembly: Firebolt 9

Assembly: Firebolt 9

Installation: Firebolt 94

Removal: Lightning/Ulysses 95

Disassembly: Lightning/Ulysses 97

Assembly: Lightning/Ulysses 97

Installation: Lightning/Ulysses 98

9 FAIRING SUPPORT BRACKET:

FIREBOLT

Removal 99

Installation 99

0 DEFLECTORS: XB9SX/XB STT/XB X

Removal and Disassembly 0

Assembly and Installation 0

GRILLE: XB9SX/XB STT/XB X

General 0

Removal and Installation 0

FRONT MODULES:

LIGHTNING/ULYSSES

Removal 0

Installation 04

HANDLEBARS: FIREBOLT

General 05

Removal 05

Right Clip On 05

Left Clip On 05

Installation 05

Right Clip On 05

Left Clip On 05

4 HANDLEBARS: LIGHTNING/ULYSSES

Removal 06

Installation 06

5 MIRRORS

Removal 08

Installation 08

6 FOOTPEG, HEEL GUARD AND MOUNT:

FIREBOLT/LIGHTNING

Rider 09

Wear Peg Removal 09

Footpeg Removal 09

Heel Guard Removal 09

Mount Removal 09

Mount Installation 09

Heel Guard Installation 09

Footpeg Installation 09

Wear Peg Installation 09

Passenger 09

Footpeg Removal 09

Heel Guard Removal 09

Mount Removal 09

Mount Installation 0

Heel Guard Installation 0

Footpeg Installation 0

7 HEEL GUARD AND FOOTPEG

MOUNTS: ULYSSES

Rider Footpegs

Footpeg Removal

Footpeg Installation

Passenger Footpegs

Footpeg Removal

Footpeg Installation

Mount Removal

Mount Installation

Heel Guard Replacement

8 SPROCKET COVER

Removal

Installation

9 BELT GUARDS

Removal 4

Installation 4

40 INTAKE COVER

Removal 5

Installation 5

4 SUBFRAME TAIL ASSEMBLY AND

BODY WORK: FIREBOLT

Disassembly 7

Cleaning 0

Assembly 0

VI TABLE OF CONTENTS

TABLE OF CONTENTS

4 LEFT TAIL SECTION AND BATTERY

PAN: LIGHTNING

Disassembly

Cleaning

Assembly 4

4 CENTER TAIL SECTION: LIGHTNING

Disassembly 6

Assembly 6

44 RIGHT TAIL SECTION: LIGHTNING

Disassembly 7

Assembly 7

45 LEFT TAIL SECTION AND BATTERY

PAN: XB X

Disassembly 8

Cleaning 8

Assembly 9

46 CENTER TAIL LOOP: XB X

Disassembly

Assembly

47 RIGHT TAIL SECTION: XB X

Disassembly

Assembly 4

48 SIDESTAND

General 5

Removal 5

Disassembly 5

Assembly 5

Installation 6

49 FRONT FAIRING,WINDSHIELD, AND

MIRRORS: FIREBOLT

Removal 7

Installation 7

50 WINDSHIELD AND WINDSCREEN:

LIGHTNING AND ULYSSES

Removal: Lightning 8

Installation: Lightning 8

Removal: Ulysses 9

Installation: Ulysses 9

5 NUMBER PLATES: XB STT

General 40

Removal 40

Installation 4

5 AIR SCOOPS

Ram Air Scoop 4

Removal 4

Installation 4

Engine Shroud Air Scoop 4

Removal 4

Installation 4

Oil Cooler Air Scoop 4

Removal 4

Installation 4

5 CHIN FAIRING

Removal 44

Installation 44

54 SEAT

Firebolt 45

Rider Seat 45

Pillion 45

Lightning 45

Removal 45

Installation 46

Ulysses 47

Removal 47

Installation 47

55 SEAT LOCKS

Removal: Lightning 49

Installation: Lightning 49

Removal: XB X 50

Installation: XB X 50

Pillion Lock Removal: XB R 5

Pillion Lock Installation: XB R 5

56 TRIPLE TAIL: XB X

General 5

Removal 5

Disassembly 5

Assembly 5

Installation 54

ENGINE

SPECIFICATIONS

General

ENGINE

Adjustment/Testing 5

General 5

Compression Test 5

Cylinder Leakage Test 5

Diagnosing Smoking Engine or High Oil Consumption 6

ENGINE ROTATION FOR SERVICE

General 7

Disassembly 7

Assembly

4 ENGINE REMOVAL

Disassembly 5

5 ENGINE INSTALLATION

Assembly 5

Engine Preparation for Re installation 5

Installing Engine in Frame 6

TABLE OF CONTENTS VII

TABLE OF CONTENTS

6 CYLINDER HEAD

Removal 7

Rocker Box Assemblies 7

Cylinder Head Assemblies 8

Disassembly 9

Cleaning and Inspection 4

Cylinder Heads 4

Rocker Arm Assemblies 4

Valves 4

Valve Seats 4

Valve Guides 4

Valve Springs 44

Spark Plug Threads 44

Push Rods 44

Replacing Rocker Arm Bushings 44

Replacing Valve Guides 45

Procedure For Using The Neway Valve Seat Cutter 46

Assembly 47

Push Rod Cover Installation 48

Cylinder Head Installation 49

7 CYLINDER AND PISTON

Removal/Disassembly 5

Cleaning and Inspection 5

Checking Gasket Surface 54

Measuring Cylinder Bore 54

Deglazing Cylinder 55

Fitting Piston Rings 55

Connecting Rod Bushing 57

Assembly/Installation 58

8 LUBRICATION SYSTEM

Lubrication 6

9 OIL RESERVOIR AND OIL HOSE

ROUTING

General 6

0 OIL LINE FITTINGS

Removal 64

Installation 64

OIL COOLER

General 66

Removal 66

Installation 66

OIL PRESSURE INDICATOR SWITCH

General 67

Oil Pressure Signal Light 67

Oil Pressure 67

CRANKCASE BREATHING SYSTEM

General 69

Reed Valve Replacement 69

4 OILING SYSTEM

General 7

5 OIL PUMP

General 7

Removal/Disassembly 7

Cleaning and Inspection 75

Assembly/Installation 76

6 HYDRAULIC LIFTERS

General 78

Removal 78

Cleaning and Inspection 78

Installation 79

7 GEARCASE AND CAM GEARS

General 80

Removal and Disassembly 8

Cleaning and Inspection 8

Cam and Pinion Gear Identification, Inspection and

Selection 8

Assembly and Installation 8

8 CRANKCASE

General 84

Disassembly 84

Crankcase Halves 84

Oil Filter Adapter 85

Piston Jets 86

Removal 86

Installation 86

Removing Cylinder Base Studs 86

Flywheel Assembly 86

Pinion Shaft Bearing 89

General 89

Selection 90

Replacement 90

Lapping Pinion Shaft Bearing Outer Race 9

Checking Connecting Rod Side Play 9

Assembly 94

Crankcase Halves 94

FUEL SYSTEM

4 SPECIFICATIONS

General 4

4 AIR CLEANER ASSEMBLY

Removal 4

Inspection 4

Installation 4

4 ELECTRONIC CONTROL MODULE (ECM)

Removal: Firebolt 4 5

Installation: Firebolt 4 5

Removal: Lightning 4 5

Installation: Lightning 4 5

Removal: Ulysses 4 6

Installation: Ulysses 4 6

4 4 THROTTLE POSITION SENSOR (TPS)

Removal 4 8

Installation 4 8

VIII TABLE OF CONTENTS

TABLE OF CONTENTS

4 5 IGNITION COIL

Removal 4 9

Installation 4 9

4 6 OXYGEN SENSOR

General 4 0

Removal 4 0

Installation 4 0

4 7 ENGINE TEMPERATURE SENSOR (ET)

General 4

Removal 4

Installation 4

4 8 BANK ANGLE SENSOR (BAS)

General 4

Removal 4

Firebolt 4

Lightning 4

Ulysses 4

Installation 4 4

Firebolt 4 4

Lightning 4 4

Ulysses 4 5

4 9 INTAKE AIR TEMPERATURE SENSOR

(IAT)

General 4 6

Removal 4 6

Installation 4 6

4 0 COOLING FAN

General 4 7

Removal 4 7

Installation 4 7

4 FUEL TANK VENT VALVE

General 4 8

Removal 4 8

Installation 4 8

4 FUEL CAP RETAINING RING

Removal 4 9

Installation 4 9

4 FUEL PUMP

Draining Fuel Tank 4 0

Removal 4 0

Repair 4

Fuel Pressure Regulator Replacement 4

Low Fuel Level Sensor Replacement 4

Fuel Filter Replacement 4

Fuel Pump Wire Harness Replacement 4 5

Installation 4 6

4 4 THROTTLE BODY

General 4 8

Removal 4 8

Repair 4

Throttle Position Sensor 4

Fuel Injectors 4

Installation 4

Injector Leak Testing 4

4 5 INTAKE LEAK TEST

General 4

Leak Tester 4

Parts List 4

Tester Assembly 4

Tester Adjustment 4

Procedure 4

4 6 EXHAUST SYSTEM

Removal and Disassembly 4 5

Muffler 4 5

Front Muffler Mount 4 5

Rear Muffler Bracket 4 5

Exhaust Header 4 5

Assembly and Installation 4 6

Exhaust Header 4 6

Rear Muffler Bracket 4 7

Front Muffler Mount 4 7

Muffler and Straps 4 7

4 7 EVAPORATIVE EMISSIONS CONTROL

(CA MODELS)

General 4 9

Troubleshooting 4 9

Removal: Firebolt 4 9

Vent Valve 4 9

Canister 4 9

Removal: Lightning/Ulysses 4 9

Vent Valve 4 9

Canister 4 9

Installation: Firebolt 4 9

Vent Valve 4 9

Canister 4 9

Installation: Lightning/Ulysses 4 40

Vent Valve 4 40

Canister 4 40

Hose Routing 4 4

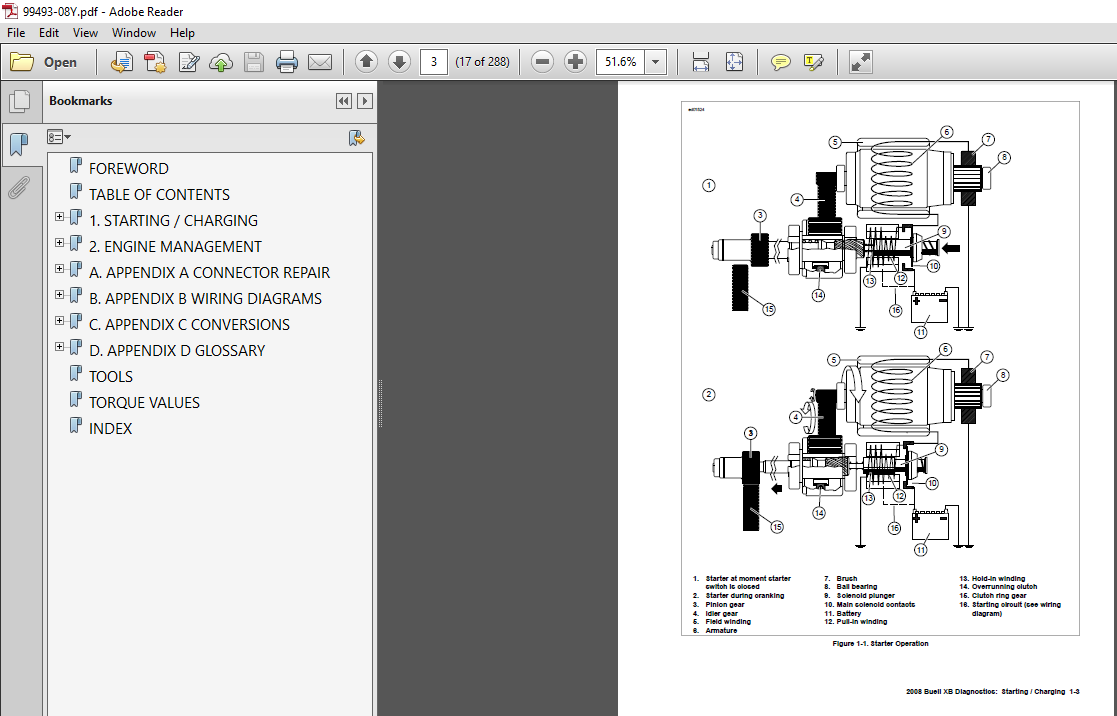

ELECTRIC STARTER

5 SPECIFICATIONS

General 5

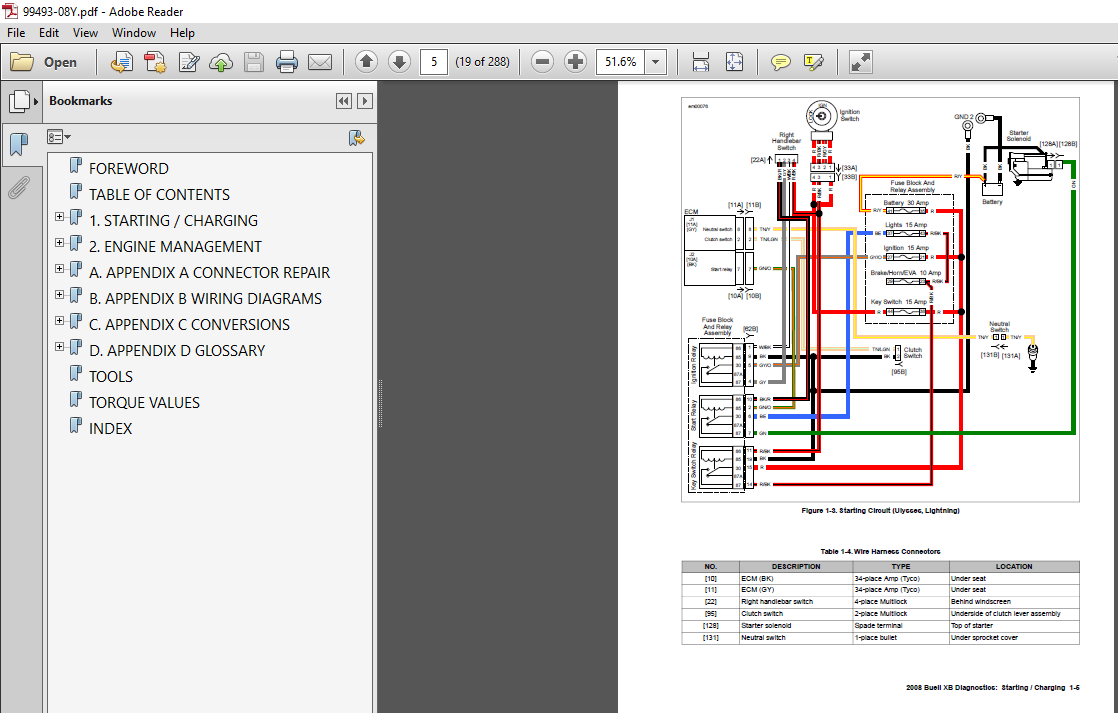

5 STARTER

General 5

Starter Relay 5

Wiring Diagrams 5

Removal 5

Disassembly, Inspection, and Repair 5

Assembly 5 6

Installation 5 7

5 STARTER SOLENOID

Replacement 5 9

Disassembly 5 9

Assembly 5 9

TABLE OF CONTENTS IX

TABLE OF CONTENTS

DRIVE/TRANSMISSION

6 SPECIFICATIONS

General 6

6 PRIMARY COVER

Removal 6

Primary Chain Adjuster Replacement 6

Installation 6 4

6 CLUTCH RELEASE MECHANISM

Disassembly 6 6

Cleaning and Inspection 6 6

Assembly 6 7

6 4 CLUTCH

General 6 8

Removal 6 0

Clutch Pack Cleaning and Inspection 6

Adjusting Screw Disassembly/Assembly 6

Assembly and Installation 6

6 5 PRIMARY CHAIN

General 6 5

Removal 6 5

Clutch Shell/Hub Inspection 6 6

Clutch Shell Bearing Replacement 6 7

Installation 6 8

6 6 DRIVE BELT AND IDLER PULLEY

General 6

Drive Belt Removal 6

Drive Belt Installation 6

Idler Pulley Removal 6

Idler Pulley Installation 6

6 7 TRANSMISSION

General 6 5

6 8 CASE DISASSEMBLY FOR

TRANSMISSION REMOVAL

General 6 6

Right Crankcase Removal 6 6

6 9 TRANSMISSION DISASSEMBLY

Transmission Removal From Left Crankcase 6 9

Mainshaft/Countershaft 6

Mainshaft Disassembly 6

Cleaning and Inspection 6 4

Countershaft Disassembly 6 4

Cleaning and Inspection 6 4

6 0 TRANSMISSION ASSEMBLY

Mainshaft Assembly 6 6

Countershaft Assembly 6 6

6 MAIN DRIVE GEAR AND BEARING

General 6 8

Removal 6 8

Main Drive Gear Bearing 6 9

Disassembly 6 40

Assembly 6 40

Installation 6 4

Main Drive Gear Ball Bearing 6 4

Main Drive Gear 6 4

Main Drive Gear Seal 6 4

6 TRANSMISSION RIGHT CASE

BEARINGS

Removal 6 45

Countershaft Needle Bearing 6 45

Shifter Drum Bushing 6 45

Installation 6 45

Countershaft Needle Bearing 6 45

Shifter Drum Bushing 6 45

6 TRANSMISSION LEFT CASE

BEARINGS

Removal 6 47

Mainshaft and Countershaft Bearings 6 47

Shift Drum Bearing 6 47

Installation 6 47

Mainshaft and Countershaft Bearings 6 47

Shift Drum Bushing 6 47

6 4 TRANSMISSION INSTALLATION

Installation 6 48

Shifter Forks and Drum Assembly 6 49

Installing Right Crankcase 6 50

6 5 SHIFTER SHAFT

Installation 6 5

6 6 TRANSMISSION SPROCKET

Removal 6 54

Installation 6 55

ELECTRICAL

7 SPECIFICATIONS

General 7

7 IGNITION SYSTEM

General 7

Troubleshooting 7

7 IGNITION/HEADLAMP KEY SWITCH

General 7 5

Removal: Firebolt 7 5

Disassembly: Firebolt 7 6

Assembly: Firebolt 7 6

Installation: Firebolt 7 7

Removal: Lightning 7 7

Disassembly: Lightning 7 9

Assembly: Lightning 7 9

Installation: Lightning 7

Removal: Ulysses 7

Disassembly: Ulysses 7

Assembly: Ulysses 7

X TABLE OF CONTENTS

TABLE OF CONTENTS

Installation: Ulysses 7 4

7 4 SPARK PLUG CABLES

General 7 5

Removal 7 5

Inspection 7 5

Installation 7 5

7 5 CHARGING SYSTEM

General 7 7

Alternator 7 7

Voltage Regulator 7 7

7 6 BATTERY CABLES

Removal 7 9

Installation 7 9

7 7 VOLTAGE REGULATOR

General 7

Removal 7

Installation 7

7 8 ALTERNATOR

Removal and Disassembly 7

Rotor 7

Stator 7

Cleaning and Inspection 7 4

Assembly and Installation 7 4

7 9 HEATED HAND GRIPS: ULYSSES

Heated Hand Grips 7 5

Removal 7 5

Installation 7 5

7 0 HORN

Removal 7 8

Installation 7 8

Troubleshooting 7 9

7 TURN SIGNAL FLASHER

Removal 7 0

Installation 7 0

7 FRONT TURN SIGNALS

Bulbs 7

Repair 7

Connections and Wire Routing 7

Firebolt 7

Removal 7

Installation 7 5

Lightning 7

Removal 7

Installation 7

Ulysses 7

Removal 7

Installation 7 6

7 REAR TURN SIGNALS

Bulbs 7 5

Connections and Wire Routing 7 5

Firebolt 7 5

Removal 7 5

Installation 7 5

Lightning 7 6

Removal 7 6

Installation 7 6

Ulysses 7 7

Remove 7 7

Installation 7 7

7 4 INTERACTIVE EXHAUST SYSTEM

General 7 9

Removal 7 4

Installation 7 4

7 5 HEADLIGHT

General 7 4

Headlight Bulbs: Firebolt 7 4

Removal 7 4

Installation 7 4

Headlight Bulbs: Lightning and Ulysses 7 44

Removal 7 44

Installation 7 45

7 6 TAIL LAMP

Firebolt/Lighting 7 48

Removal 7 48

Installation 7 48

Ulysses 7 49

Removal 7 49

Installation 7 49

7 7 LICENSE PLATE LAMP ASSEMBLY

Lightning 7 50

Removal 7 50

Installation 7 50

Ulysses 7 50

Removal and Disassembly 7 50

Assembly and Installation 7 5

7 8 MAIN FUSE AND FUSES

General 7 5

Fuses 7 5

Main Fuse 7 5

7 9 NEUTRAL INDICATOR SWITCH

General 7 56

Testing 7 56

Removal and Installation 7 56

7 0 CRANKSHAFT POSITION SENSOR

(CKP)

GENERAL 7 57

REMOVAL 7 57

Installation 7 57

7 VEHICLE SPEED SENSOR (VSS)

Removal 7 59

Installation 7 59

TABLE OF CONTENTS XI

TABLE OF CONTENTS

7 INSTRUMENT MODULE

General 7 60

Removal 7 60

Bulb Replacement 7 60

Installation 7 6

7 MAIN WIRE HARNESS

General 7 6

Removal 7 6

Installation 7 70

7 4 INTERACTIVE EXHAUST HARNESS:

XB MODELS

Firebolt 7 78

Removal 7 78

Installation 7 78

Lightning 7 79

Removal 7 79

Installation 7 79

Ulysses 7 80

Removal 7 80

Installation 7 80

7 5 SPROCKET COVER WIRING

General 7 8

Removal 7 8

7 6 AUXILIARY POWER OUTLETS:

ULYSSES

General 7 8

Accessory Load Test 7 8

APPENDIX A CONNECTOR REPAIR

A AMP PLACE CONNECTORS

AMP Place Connector Repair A

General A

Separating Pin and Socket Housings A

Mating Pin and Socket Housings A

Removing Socket Terminals A

Installing Socket Terminal A

Removing Pin Terminal A

Installing Pin Terminal A

A AMP MULTILOCK CONNECTORS

AMP Multilock Connector Repair A

General A

Separating Pin and Socket Housings A

Mating Pin and Socket Housings A

Removing Terminals from Housing A

Inserting Terminals into Housing A 4

Preparing Wire Leads for Crimping A 4

Crimping Terminals to Leads A 5

Inspecting Crimped Terminals A 6

A AUTOFUSE ELECTRICAL

CONNECTORS

Autofuse Connector Repair A 7

General A 7

Disassembly A 7

Assembly A 7

A 4 DELPHI CONNECTORS

Delphi Connector Repair A 8

General A 8

Separating Pin and Socket Housings A 8

Mating Pin and Socket Housings A 8

Removing Socket Terminals A 8

Installing Socket Terminals A 8

A 5 DEUTSCH ELECTRICAL CONNECTORS

Deutsch Connector Repair A 0

General A 0

Separating Pin and Socket Housings A 0

Mating Pin and Socket Housings A 0

Removing Socket Terminals A 0

Installing Socket Terminals A 0

Removing Pin Terminals A

Installing Pin Terminals A

Crimping Terminals A

A 6 DEUTSCH STANDARD TERMINAL

REPAIR

Deutsch Standard Terminal Crimps A 4

Preparing Wire Leads for Crimping A 4

Crimping Terminal to Lead A 4

Inspecting Crimps A 4

A 7 DEUTSCH SOLID BARREL MINI

TERMINAL REPAIR

Deutsch Solid Barrel Terminal Crimps A 5

Preparing Wire Leads For Crimping A 5

Adjusting Crimper Tool A 5

Crimping a Barrel Contact To Wire Lead A 5

Inspecting Crimps A 5

A 8 DEUTSCH MINI TERMINAL REPAIR

Deutsch Mini Terminal Crimps A 7

Preparing Wire Leads for Crimping A 7

Crimping a Mini Terminal to Wire Lead A 7

Inspecting Crimps A 7

A 9 MOLEX CONNECTORS

Molex Connector Repair A 8

Separating Pin and Socket Housings A 8

Mating Pin and Socket Housings A 8

Removing Terminals A 8

Installing Terminals A 8

Crimp Terminal to Lead A 9

Prepare Lead A 9

Prepare Tool A 9

Position Terminal in the Punch/Die A 0

Insert Stripped Lead A 0

Crimp Terminal to Lead A 0

Inspect Crimp A

A 0 PACKARD 50 METRI PACK

CONNECTORS

50 Metri Pack Connector Repair A

XII TABLE OF CONTENTS

TABLE OF CONTENTS

General A

Separating Pin and Socket Housings A

Mating Pin and Socket Housings A

Removing Socket Terminal A

Inserting Socket Terminal A

A PACKARD 80 METRI PACK RELAY

AND FUSE BLOCK CONNECTORS

Fuse Block Repair A 4

Removing Socket Terminals A 4

Installing Socket Terminals A 4

Crimping Terminals A 4

A PACKARD 480 METRI PACK

CONNECTORS

480 Metri Pack Connector Repair A 5

General A 5

Separating Pin and Socket Housings A 5

Mating Pin and Socket Housings A 5

Removing Socket Terminals A 5

Installing Socket Terminals A 5

A PACKARD 6 0 METRI PACK

CONNECTORS

6 0 Metri Pack Connector Repair A 6

General A 6

Separating Pin and Socket Housings A 6

Mating Pin and Socket Housings A 6

Removing Socket Terminal A 6

Installing Socket Terminal A 6

A 4 PACKARD METRI PACK TERMINALS

Metri Pack Terminal Crimps A 7

Matching Terminal To Crimper A 7

Preparing Wire Lead A 7

Crimping Wire Core A 7

Crimping Insulation/Seal A 7

Inspecting Crimps A 8

A 5 PACKARD ECM CONNECTOR

Packard 00W Connector Repair A 9

General A 9

Separating Socket Housing From ECM A 9

Mating Socket Housing To ECM A 9

Removing Socket Terminal A 9

Installing Socket Terminal A 9

Crimping Terminals A 9

A 6 PACKARD MICRO 64 CONNECTORS

Packard Micro 64 Connector Repair A

General A

Separating Pin and Socket Housings A

Mating Pin and Socket Housings A

Removing Terminal A

Installing Terminal A

Preparing Wire Leads for Crimping A

Crimping Terminals A

Inspecting Crimps A

A 7 SEALED SPLICE CONNECTORS

Sealed Splice Connector Repair A 4

General A 4

Preparing Wire Leads A 4

Splicing Wire Leads A 4

Inspecting Seals A 4

APPENDIX B WIRING

B WIRING DIAGRAMS

Connector Locations B

Function/Location B

Place and Color B

Connector Number B

Repair Instructions B

Wiring Diagram Information B

Wire Color Codes B

Wiring Diagram Symbols B

008 Buell Wiring Diagrams B 4

APPENDIX C CONVERSIONS

C LENGTH CONVERSION

Conversion Table C

C FLUID CONVERSION

United States System C

Metric System C

British Imperial System C

C TORQUE CONVERSION

United States System C

Metric System C

APPENDIX D HOSE AND WIRE

ROUTING

D APPENDIX D: HOSE AND WIRE

ROUTING

Firebolt D

Lightning D

Ulysses D 5

APPENDIX E ACTIVE INTAKE

(JAPANESE MODELS)

E ACTIVE INTAKE SYSTEM (JAPANESE

MODELS ONLY)

General E

Active Intake System E

Diagnostic Notes E

Verify Settings E

WOT Check E

Cable E

Adjustment E

Throttle Stop Screw E

Removal E 4

TABLE OF CONTENTS XIII

TABLE OF CONTENTS

Installation E 5

APPENDIX F GLOSSARY

F GLOSSARY

Acronyms and Abbreviations F

REFERENCE MATERIAL

TOOLS I

TORQUE VALUES VII

INDEX XXV

XIV TABLE

PLEASE NOTE:

- This is the SAME exact manual used by your dealers to fix your vehicle.

- The same can be yours in the next 2-3 mins as you will be directed to the download page immediately after paying for the manual.

- Any queries / doubts regarding your purchase, please feel free to contact [email protected]