Liebherr A904c Litronic Hydraulic Excavator Operation Maintenance Manual

FILE DETAILS:

FILE TYPE:PDF

MANUAL LANGUAGE:ENGLISH

PAGES:298

DOWNLOADABLE:YES

DESCRIPTION:

- This operating manual has been specifically devised for machine operators and maintenance personnel. It contains important information and tips regarding the maintenance and proper operation of the machine. It assists you in becoming familiar with the functions and features of the machine and helps prevent incorrect operation. By strictly adhering to the instructions in the operating manual, you can significantly enhance the reliability and service life of the machine.

- The operating manual is an integral part of the scope of delivery of the machine. Ensure that a copy is at all times available in the storage compartment in the operator’s cab. Carefully read the operating manual before starting the machine and then regularly read it again.

- All persons carrying out work on or with the machine must be fully familiar with the content of the operating manual and must adhere to the instructions. Such work include: Machine operation including tooling, troubleshooting during work, general care and cleaning, disposal of fuels and lubricants. Maintenance including inspection, servicing and repair. Transport or loading of the machine.

- The machine owner must ensure that this operating manual is complemented with the relevant statutory regulations for accident prevention and the protection of the environment. Apart from the instructions in this operating manual and the statutory accident prevention, health and safety regulations applicable in the country of operation, all personnel working on or with the machine must adhere to best practice for safe and proper operation.

SCREENSHOT OF THE MANUAL:

TABLE OF CONTENTS:

- Liebherr A904c Litronic Hydraulic Excavator Operation Maintenance Manual

1 Product description . 1-1

1.1 Design and overview . 1-1

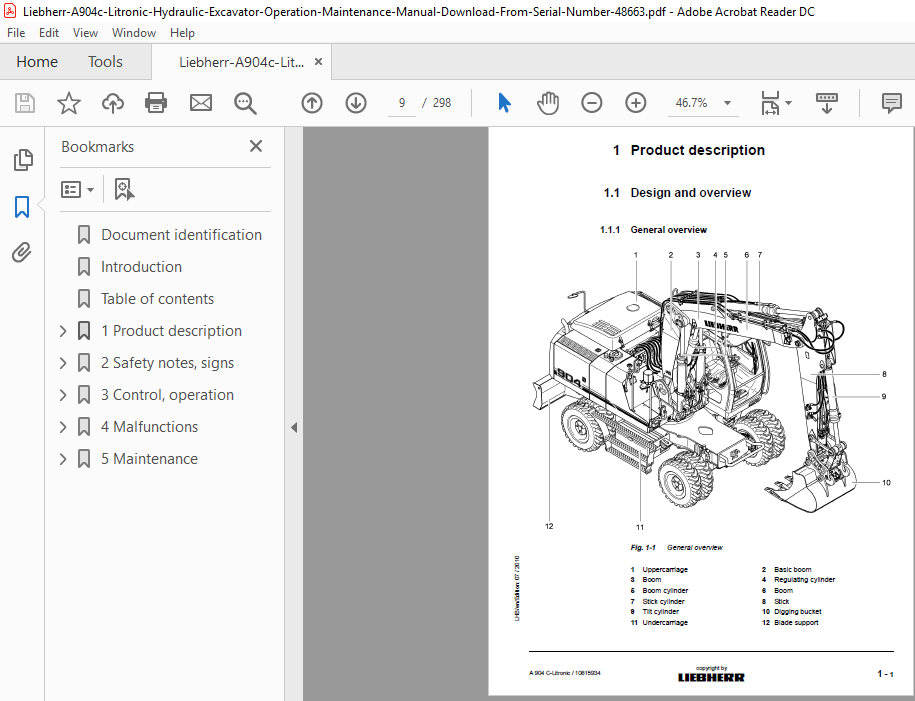

1.1.1 General overview . 1-1

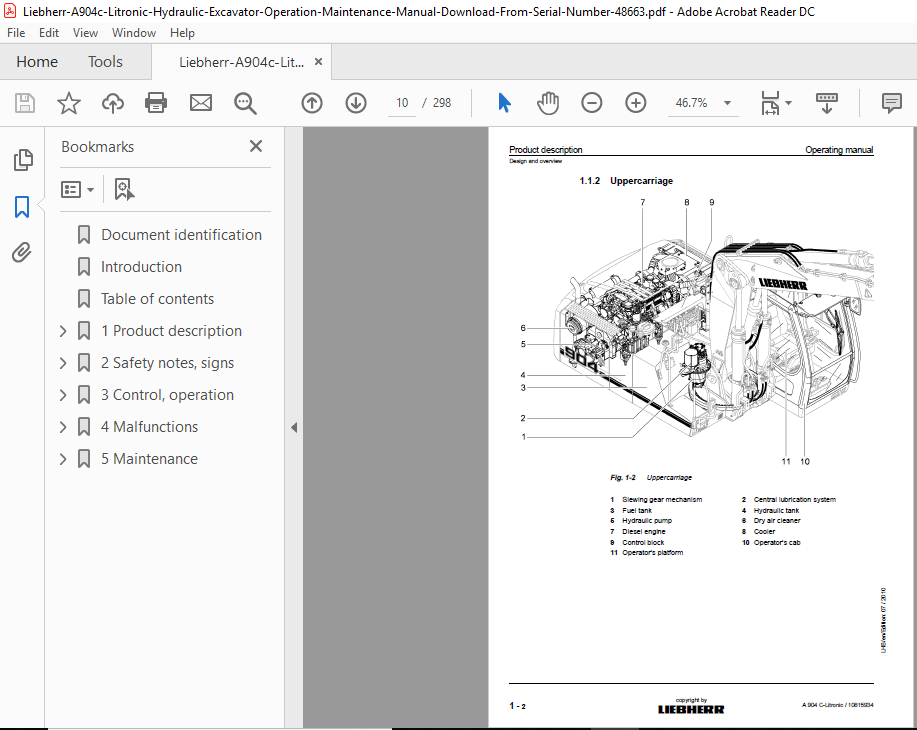

1.1.2 Uppercarriage . 1-2

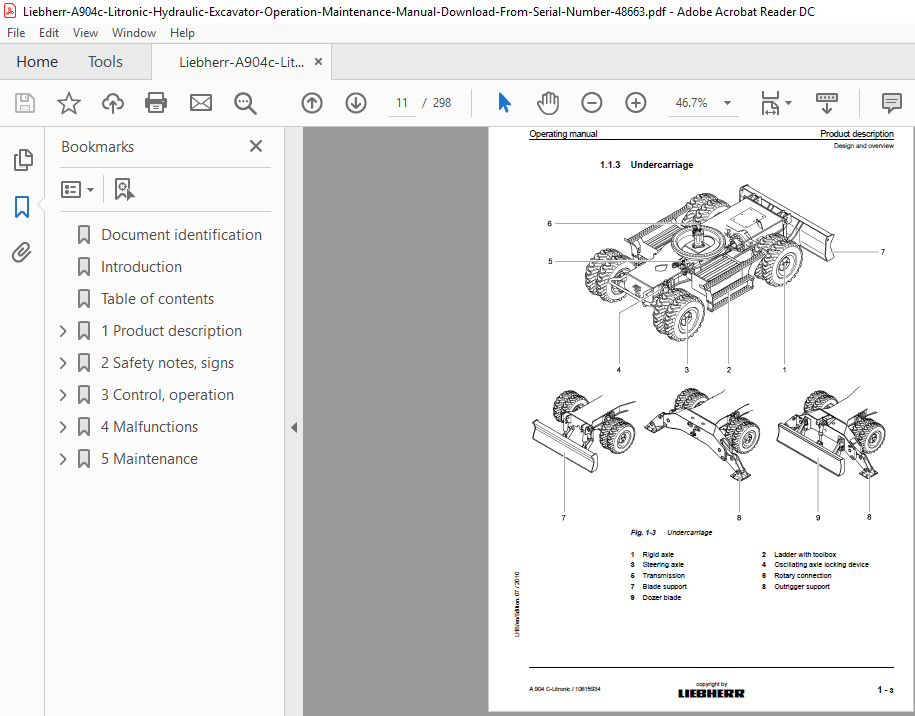

1.1.3 Undercarriage . 1-3

1.2 Vibration emissions 1-4

1.3 Sound emission . 1-5

1.4 EC Declaration of Conformity 1-6

1.5 Technical data . 1-7

2 Safety notes, signs 2-1

2.1 Symbols used in this operating manual . 2-1

2.2 Proper use . 2-2

2.3 Safety instructions . 2-2

2.3.1 General safety instructions . 2-2

2.3.2 Crushing and burn prevention 2-3

2.3.3 Fire and explosion prevention 2-4

2.4 Signs on the machine 2-4

2.4.1 Safety and information signs 2-4

2.4.2 ID tag 2-12

3 Control, operation 3-1

3.1 Operating and control elements . 3-1

3.1.1 Overview of operator’s platform 3-1

3.1.2 Keypad . 3-3

3.1.3 Monitoring screen . 3-6

3.1.4 Main screen 3-9

3.1.5 Information symbols on the main screen 3-11

3.1.6 Operator’s menu . 3-13

3.2 Control . 3-27

3.2.1 Entering and exiting the operator’s cab 3-27

3.2.2 Safety lever 3-29

3.2.3 Operator seat . 3-29

3.2.4 Operator seat . 3-33

3.2.5 Adjusting the steering column 3-36

3.2.6 Windscreen 3-37

3.2.7 Sun blind 3-38

3.2.8 Emergency exit through rear window . 3-39

3.2.9 Inside lighting . 3-39

3.2.10 Fire extinguisher (optional equipment)* 3-40

3.2.11 Windshield wiper 3-40

3.2.12 Lighting . 3-42

3.2.13 Radio mute mode (optional equipment) . 3-43

3.2.14 Heating and air-conditioning system 3-43

3.3 Operation . 3-49

3.3.1 Safety instructions 3-49

3.3.2 Starting machine 3-50

3.3.3 Switching off the diesel engine . 3-56

3.3.4 Starting aids . 3-56

3.3.5 Jump start procedure . 3-59

3.3.6 Travelling operation 3-60

3.3.7 Travel warning device (option) . 3-62

3.3.8 On-road travelling . 3-62

3.3.9 Oscillating axle locking device 3-67

3.3.10 Support . 3-69

3.3.11 Operation of dozer blade (optional equipment) 3-71

3.4 Working with the machine 3-71

3.4.1 Safety Instructions 3-71

3.4.2 Sensor controlled low idle automatic 3-75

3.4.3 Working position . 3-76

3.4.4 Operating working attachment 3-77

3.4.5 Swivelling the uppercarriage 3-78

3.4.6 Halting the uppercarriage . 3-78

3.4.7 Lowering the working attachment when engine is shut off . 3-80

3.4.8 Activating boom or attachment tool 3-81

3.4.9 Moving the boom 3-82

3.4.10 Adjustment of attachment tool 3-83

3.4.11 Operating the attachment tool (by pedals, push buttons) . 3-83

3.4.12 Changeover of control (optional equipment) 3-85

3.4.13 Operating attachment tool (mini joystick control, optional equipment) . 3-85

3.4.14 Changeover of joystick control (optional equipment) 3-88

3.4.15 Stroke limitation (optional equipment) 3-88

3.4.16 Adjusting stroke limitation settings . 3-91

3.4.17 Magnetic system (option) . 3-94

3.5 Installation and removal of attachment parts . 3-94

3.5.1 Safety Instructions 3-94

3.5.2 Installation and removal of digging tool 3-96

3.5.3 Attachment of grapple to bucket stick . 3-98

3.5.4 Hydraulic quick-change adapter (optional equipment) . 3-101

3.5.5 Hydraulic quick-change adapter with LIKUFIX (optional equipment) . 3-106

3.5.6 Mechanical quick-change adapter (optional equipment) 3-107

3.6 General working methods 3-111

3.6.1 Tips for the proper operation of the machine preventing damage and wear 3-111

3.6.2 Preparation . 3-113

3.6.3 Working with the backhoe bucket . 3-114

3.6.4 Loading transport vehicle . 3-115

3.6.5 Grading work 3-116

3.6.6 Working with grapples 3-117

3.6.7 Excavating and moving material with grapples . 3-117

3.6.8 Working with the hydraulic hammer 3-118

3.6.9 Load lifting operation 3-120

3.6.10 Use of quick-change adapter for load lifting operation . 3-120

3.6.11 Overload warning system (optional equipment) . 3-121

3.7 Parking and exiting machine 3-123

3.8 Transport 3-123

3.8.1 Safety instructions 3-123

3.8.2 Transportation on low-loader 3-124

3.8.3 Loading with crane . 3-126

4 Malfunctions . 4-1

4.1 Error code list . 4-1

4.2 Faults and remedies 4-8

4.2.1 Diesel engine and fuel system 4-8

4.2.2 Hydraulic system 4-10

4.2.3 Travelling 4-11

4.2.4 Brakes 4-12

4.2.5 Electrical system . 4-12

4.2.6 Heating and air conditioning system . 4-13

4.2.7 Working attachment 4-13

4.3 Fuses and relays 4-13

4.3.1 Fuse box E50 . 4-14

4.3.2 ESP02 printed circuit board 4-15

4.4 Emergency operation . 4-16

4.4.1 Purpose 4-16

4.4.2 Identifying solenoid valve . 4-17

4.4.3 Emergency mode control . 4-17

4.4.4 Emergency operation of hydraulic pump 4-20

4.4.5 Stroke limitation emergency operation (optional equipment) . 4-21

4.4.6 Emergency gear shifting . 4-22

4.4.7 Towing the machine . 4-22

4.4.8 Disengaging transmission (emergency release) 4-23

5 Maintenance . 5-1

5.1 Safety instructions . 5-1

5.1.1 General safety instructions . 5-1

5.1.2 Checking for cracks 5-1

5.1.3 Welding 5-2

5.1.4 Fuels, lubricants and process chemicals 5-2

5.1.5 Repair . 5-2

5.1.6 Electrical system 5-3

5.1.7 Pressure accumulator 5-3

5.1.8 Hydraulic hoses and lines 5-4

5.1.9 Cab protection (FOPS) . 5-5

5.2 Maintenance access doors 5-5

5.2.1 Overview of access doors 5-5

5.2.2 Door locking mechanism 5-6

5.2.3 Engine hood locking mechanism 5-7

5.3 Cleaning machine 5-7

5.4 Care for rubber components 5-8

5.5 Tyres 5-8

5.5.1 Checking tyre pressure 5-8

5.5.2 Foam tyres . 5-9

5.5.3 Checking wheel lugs for proper fit 5-9

5.6 Fuels, lubricants and process chemicals . 5-10

5.6.1 General information 5-10

5.6.2 Filling volumes, lubricating chart 5-11

5.7 Specifications for fuels, lubricants and process chemicals 5-13

5.7.1 Diesel fuels . 5-13

5.7.2 Lubricating oil for the diesel engine 5-14

5.7.3 Coolant for the diesel engine 5-16

5.7.4 Hydraulic oil 5-19

5.7.5 Lubricants for axles and gearboxes . 5-23

5.7.6 Lubricating oil for transmission . 5-24

5.7.7 Grease 5-25

5.7.8 Lubricants and care products for electrical and mechanical components 5-25

5.8 Diesel engine . 5-26

5.8.1 Checking the oil level in the diesel engine . 5-26

5.8.2 Changing the diesel engine oil . 5-26

5.8.3 Ribbed V-belt for A/C compressor and alternator installation . 5-28

5.8.4 Crankcase bleeding point . 5-28

5.8.5 Grease the starter tooth ring 5-29

5.9 Cooling system 5-30

5.9.1 Checking and cleaning the cooling system 5-30

5.9.2 Checking coolant level . 5-30

5.9.3 Changing coolant . 5-31

5.9.4 Checking coolant, adjusting mixing ratio 5-33

5.10 Fuel system . 5-37

5.10.1 Refuelling . 5-37

5.10.2 Dewatering fuel tank . 5-38

5.10.3 Emptying and cleaning fuel tank 5-39

5.10.4 Maintenance of fuel filter 5-40

5.10.5 Bleeding fuel system 5-42

5.11 Dry air filter . 5-44

5.11.1 Replacing main element . 5-45

5.11.2 Changing the safety element 5-46

5.11.3 Checking the clean air line . 5-47

5.12 Hydraulic system 5-47

5.12.1 Preparations . 5-47

5.12.2 Checking the oil level in the hydraulic tank . 5-48

5.12.3 Depressurizing the hydraulic system 5-48

5.12.4 Replacing the breather filter . 5-49

5.12.5 Emptying and refilling the hydraulic tank 5-49

5.12.6 Return filter . 5-50

5.12.7 Control oil filter 5-52

5.12.8 Control circuit 5-52

5.12.9 Bleeding the hydraulic pump 5-53

5.12.10 Bypass oil filter (optional equipment) 5-54

5.12.11 Maintenance of hydraulic cylinders 5-55

5.12.12 Replacing hydraulic hoses 5-56

5.13 Changing the oil on components . 5-56

5.13.1 General notes . 5-56

5.13.2 Swin gear – oil change 5-57

5.13.3 Transmission – oil change 5-58

5.13.4 Steering and rigid axle – oil change 5-58

5.13.5 Wheel head – oil change 5-59

5.13.6 Pump distributor gear – oil change 5-60

5.14 Checking brake pads for wear . 5-60

5.15 Electrical system 5-61

5.15.1 Notes regarding the electrical system 5-61

5.15.2 Battery main switch 5-61

5.15.3 Battery care 5-62

5.15.4 Slip ring body (optional equipment) 5-63

5.16 Heating and air-conditioning system 5-64

5.16.1 Recirculated and ambient air filter 5-64

5.16.2 Heating system . 5-65

5.16.3 air-conditioning system . 5-65

5.17 Automatic lubrication of the machine . 5-66

5.17.1 Semi-automatic central greasing system 5-66

5.17.2 Fully automatic central greasing system (optional extra) 5-68

5.18 Manual lubrication of the machine . 5-70

5.18.1 Steering axle . 5-70

5.18.2 Central lubrication system of steering axle (optional equipment) . 5-71

5.18.3 Digging buckets / bucket tilting device 5-71

5.18.4 Attachments (optional equipment) 5-72

5.18.5 Hydraulic quick change adapter . 5-73

5.18.6 Mechanical quick-change adapter 5-73

5.19 Couplings of the quick-change adapter systems (optional equipment) . 5-74

5.19.1 Hydraulic coupling 5-74

5.19.2 LIKUFIX electric coupling . 5-75

5.20 Parking and swing gear brake . 5-76

5.21 General maintenance tasks . 5-77

5.21.1 Replacing wear parts 5-77

5.21.2 Replacing teeth on digging tool 5-77

5.21.3 Welded parts on the machine . 5-79

5.22 Maintenance and inspection schedule . 5-7

VIDEO PREVIEW:

PLEASE NOTE:

⦁ This is the SAME manual used by the dealers to troubleshoot any faults in your vehicle. This can be yours in 2 minutes after the payment is made.

⦁ Contact us at [email protected] should you have any queries before your purchase or that you need any other service / repair / parts operators manual.