Komatsu Hydraulic Excavator PC600 8PC600 LC-8 PC800 K50001 PC 800 LC-K Service Repair Manual Download

FILE DETAILS:

Komatsu Hydraulic Excavator PC600 8PC600 LC-8 PC800 K50001 PC 800 LC-K Service Repair Manual Download

LANGUAGE:ENGLISH

PAGES:1914

DOWNLOADABLE:YES

FILE TYPE:PDF

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

- Komatsu Hydraulic Excavator PC600 8PC600 LC-8 PC800 K50001 PC 800 LC-K Service Repair Manual Download

- 1. Composition of shop manual This shop manual contains the necessary technical information for services performed in a workshop. For ease of understanding, the manual is divided into the following sections. 00. Index and foreword This section explains the shop manuals list, table of contents, safety, and basic information.

- 01. Specification This section explains the specifications of the machine.

- 10. Structure, function and maintenance standard This section explains the structure, function, and maintenance standard values of each component. The structure and function sub-section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting. The maintenance standard sub-section explains the criteria and remedies for disassembly and service.

- 20. Standard value table This section explains the standard values for new machine and judgement criteria for testing, adjusting, and troubleshooting. This standard value table is used to check the standard values in testing and adjusting and to judge parts in troubleshooting.

- 30. Testing and adjusting This section explains measuring instruments and measuring methods for testing and adjusting, and method of adjusting each part. The standard values and judgement criteria for testing and adjusting are explained in Testing and adjusting.

- 40. Troubleshooting This section explains how to find out failed parts and how to repair them. The troubleshooting is divided by failure modes. The “S mode” of the troubleshooting related to the engine may be also explained in the Chassis volume and Engine volume. In this case, see the Chassis volume.

- 50. Disassembly and assembly This section explains the special tools and procedures for removing, installing, disassembling, and assembling each component, as well as precautions for them. In addition, tightening torque and quantity and weight of coating material, oil, grease, and coolant necessary for the work are also explained.

- 90. Diagrams and drawings (chassis volume)/Repair and replacement of parts (engine volume) q Chassis volume This section gives hydraulic circuit diagrams and electrical circuit diagrams. q Engine volume This section explains the method of reproducing, repairing, and replacing parts.

TABLE OF CONTENTS:

Komatsu Hydraulic Excavator PC600 8PC600 LC-8 PC800 K50001 PC 800 LC-K Service Repair Manual Download

00 Index and foreword.................................................................... 3

Organization list of the shop manual................................................. 4

Table of contents.................................................................... 6

00 Index and foreword.................................................................... 15

Foreword and general information..................................................... 16

Safety notice.................................................................... 16

How to read the shop manual...................................................... 20

Explanation of terms for maintenance standard.................................... 22

Handling electric equipment and hydraulic component.............................. 24

How to read electric wire code................................................... 32

Method of disassembling and connecting push-pull type coupler.................... 35

Standard tightening torque table................................................. 38

Conversion table................................................................. 42

01 Specification......................................................................... 49

Specification and technical data..................................................... 50

Specification drawings........................................................... 50

Working range drawings........................................................... 51

Specifications................................................................... 52

Weight table..................................................................... 58

Table of fuel, coolant and lubricants............................................ 60

10 Structure, function and maintenance standard.......................................... 63

Engine and cooling system............................................................ 64

Parts related to engine.......................................................... 64

PTO.............................................................................. 66

Fan, control and PTO lubrication pump............................................ 68

Radiator, oil cooler............................................................. 69

10 Structure, function and maintenance standard.......................................... 71

Power train.......................................................................... 72

Power train...................................................................... 72

Final drive...................................................................... 75

Sprocket......................................................................... 78

Swing circle..................................................................... 80

Swing machinery.................................................................. 82

10 Structure, function and maintenance standard.......................................... 85

Undercarriage and frame.............................................................. 86

Track frame, recoil spring....................................................... 86

Idler............................................................................ 88

Carrier roller................................................................... 90

Track roller..................................................................... 91

Track shoe....................................................................... 92

10 Structure, function and maintenance standard.......................................... 99

Hydraulic system, Part 1.............................................................100

Hydraulic piping drawing.........................................................100

Hydraulic tank, hydraulic filter.................................................102

Hydraulic pump (piston pump).....................................................104

Line oil filter..................................................................132

Cooling fan pump.................................................................134

Cooling fan motor................................................................142

10 Structure, function and maintenance standard..........................................149

Hydraulic system, Part 2.............................................................150

Control valve....................................................................150

Swing motor......................................................................169

Swing brake......................................................................172

Safety valve.....................................................................173

Reverse prevention valve.........................................................175

Center swivel joint..............................................................178

Travel motor.....................................................................179

Parking brake....................................................................184

Brake valve......................................................................186

Set pressures varying mechanism..................................................189

Valve control....................................................................190

Work equipment, swing PPC valve..................................................192

Travel PPC valve.................................................................196

Service PPC valve................................................................198

PPC accumulator..................................................................199

PPC shuttle valve................................................................200

Solenoid valve...................................................................201

Boom holding valve...............................................................206

Boom LOWER regeneration valve....................................................210

Hydraulic drift prevention valve.................................................214

Hydraulic cylinder...............................................................220

10 Structure, function and maintenance standard..........................................223

Work equipment.......................................................................224

Work equipment...................................................................224

Dimensions of work equpment......................................................226

10 Structure, function and maintenance standard..........................................231

Cab and its attachments..............................................................232

Air conditioner piping...........................................................232

10 Structure, function and maintenance standard..........................................235

Engine control.......................................................................236

Machine control system diagram.......................................................241

Monitor system.......................................................................265

Sensors..............................................................................280

20 Standard value table..................................................................285

Standard service value table.........................................................286

Standard value table for engine..................................................286

Standard value table for chassis.................................................287

30 Testing and adjusting.................................................................297

Testing and adjusting, Part 1........................................................300

Tools for testing, adjusting and troubleshooting.................................300

Measuring engine speed...........................................................302

Measuring intake air pressure (boost pressure)...................................303

Measuring exhaust gas temperature................................................304

Measuring exhaust gas color......................................................305

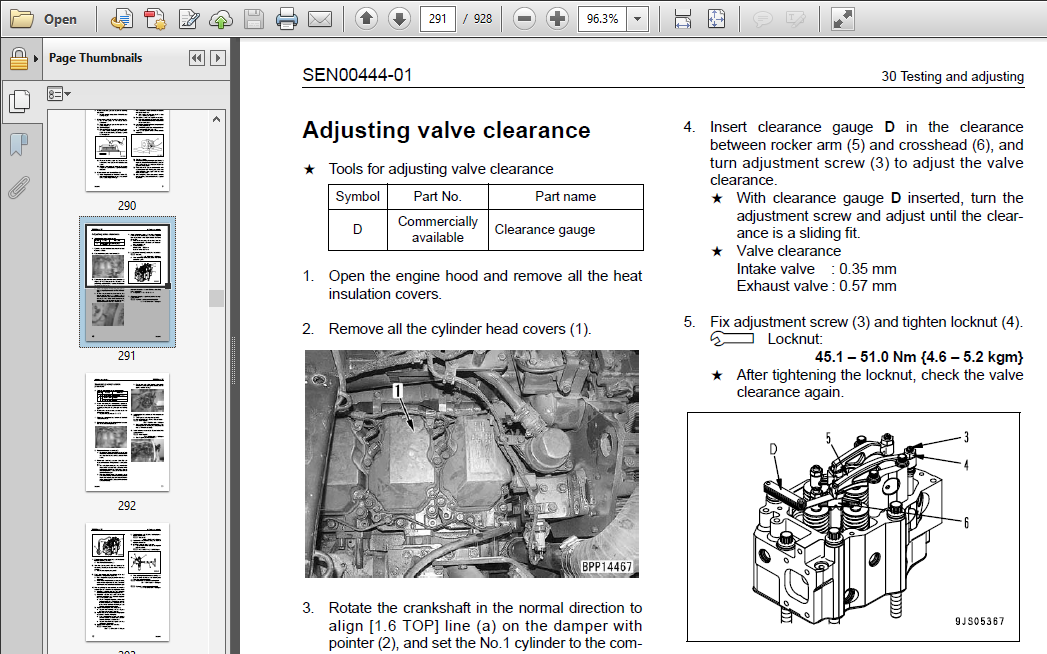

Adjusting valve clearance........................................................306

Measuring compression pressure...................................................307

Measuring blow-by pressure.......................................................309

Measuring engine oil pressure....................................................309

Handling equipment in fuel circuit...............................................310

Releasing remaining pressure in fuel system......................................310

Measuring fuel pressure..........................................................311

Reduced cylinder mode operation..................................................312

No-injection cranking............................................................312

Testing leakage from pressure limiter and return rate from injector..............313

Bleeding air from fuel circuit...................................................315

Testing fuel system for leakage..................................................316

Adjusting speed sensor...........................................................317

Testing and adjusting alternator belt tension....................................317

Testing and adjusting air conditioner compressor belt tension....................318

Testing clearance of swing circle bearing........................................319

Testing and adjusting track shoe tension.........................................320

Testing and adjusting work equipment, swing, and travel circuit oil pressures....321

Testing and adjusting control circuit oil pressure...............................326

Testing and adjusting piston pump control oil pressure...........................328

Testing servo piston stroke......................................................334

Measuring PPC valve output pressure..............................................335

Measuring outlet pressures of solenoid valve and PPC shuttle valve...............340

Adjusting work equipment, swing PPC valve........................................346

Testing and adjusting travel deviation...........................................347

Measuring fan speed..............................................................349

Measuring fan circuit oil pressure...............................................349

Inspection of locations of hydraulic drift of work equipment.....................350

Measuring oil leakage............................................................351

Releasing remaining pressure in hydraulic circuit................................355

Bleeding air from each part......................................................356

Inspection procedures for diode..................................................359

30 Testing and adjusting.................................................................361

Testing and adjusting, Part 2........................................................362

Special function of machine monitor..............................................362

Handling engine controller high voltage circuit..................................394

Preparation work for troubleshooting electrical system...........................395

Pm-CLINIC SERVICE................................................................397

Pm-CLINIC SERVICE PC600, 600LC-8.................................................402

UNDERCARRIAGE INSPECTION.........................................................403

40 Troubleshooting.......................................................................405

General information on troubleshooting...............................................406

Points to remember when troubleshooting..........................................406

Sequence of events in troubleshooting............................................407

Checks before troubleshooting....................................................408

Classification and procedures of troubleshooting.................................409

Connection table for connector pin numbers.......................................413

T-boxes and T-adapters table.....................................................436

40 Troubleshooting.......................................................................441

Troubleshooting by failure code (Display of code), Part 1............................444

40 Troubleshooting.......................................................................505

Troubleshooting by failure code (Display of code), Part 2............................508

40 Troubleshooting.......................................................................571

Troubleshooting by failure code (Display of code), Part 3............................574

40 Troubleshooting.......................................................................643

Troubleshooting of electrical system (E-mode)........................................646

40 Troubleshooting.......................................................................703

Troubleshooting of hydraulic and mechanical system (H-mode)..........................705

40 Troubleshooting.......................................................................745

Troubleshooting of engine (S-mode)...................................................747

50 Disassembly and assembly..............................................................773

General information on disassembly and assembly......................................774

How to read this manual..........................................................774

Coating materials list...........................................................776

Special tools list...............................................................779

Sketches of special tools........................................................785

50 Disassembly and assembly..............................................................791

Engine and cooling system, Part 1....................................................792

Removal and installation of engine, PTO and hydraulic pump assembly..............792

Removal and installation of radiator assembly....................................799

Removal and installation of hydraulic oil cooler assembly........................801

Removal and installation of aftercooler assembly.................................803

Removal and installation of fan motor assembly...................................805

Removal and installation of fuel tank assembly...................................809

50 Disassembly and assembly..............................................................811

Engine and cooling system, Part 2....................................................812

Removal and installation of fuel supply pump assembly............................812

Removal and installation of cylinder head assembly...............................817

Removal and installation of fuel injector assembly...............................833

Removal and installation of engine front seal....................................836

Removal and installation of engine rear seal.....................................838

50 Disassembly and assembly..............................................................843

Power train..........................................................................844

Removal and installation of PTO assembly.........................................844

Disassembly and assembly of PTO assembly.........................................846

Removal and installation of swing motor and swing machinery assembly.............849

Disassembly and assembly of swing machinery assembly.............................850

Removal and installation of swing circle assembly................................857

Disassembly and assembly of final drive assembly.................................858

50 Disassembly and assembly..............................................................869

Undercarriage and frame..............................................................870

Removal and installation of revolving frame assembly.............................870

Disassembly and assembly of 1 link in field......................................872

Removal and installation of idler, recoil spring assembly........................876

Disassembly and assembly of idler assembly.......................................877

Disassembly and assembly of recoil spring assembly...............................880

Removal and installation of track roller assembly................................882

Disassembly and assembly of track roller assembly................................883

Removal and installation of carrier roller assembly..............................886

Disassembly and assembly of carrier roller assembly..............................887

Removal and installation of revolving frame assembly.............................890

Removal and installation of counterweight assembly...............................892

Removal and installation of counterweight remover assembly.......................893

50 Disassembly and assembly..............................................................897

Hydraulic system.....................................................................898

Removal and installation of hydraulic tank assembly..............................898

Removal and installation of hydraulic pump assembly..............................900

Removal and installation of control valve and solenoid valve assembly............903

Disassembly and assembly of control valve assembly...............................905

Disassembly and assembly of main control valve assembly..........................906

Removal and installation of swing motor assembly.................................910

Removal and installation of center swivel joint assembly.........................911

Disassembly and assembly of center swivel joint assembly.........................912

Disassembly and assembly of work equipment PPC valve assembly....................913

Disassembly and assembly of travel PPC valve assembly............................915

Disassembly and assembly of hydraulic cylinder assembly..........................917

50 Disassembly and assembly..............................................................923

Work equipment.......................................................................924

Removal and installation of bucket cylinder assembly.............................924

Removal and installation of arm cylinder assembly................................926

Removal and installation of boom cylinder assembly...............................928

Removal and installation of bucket assembly......................................930

Removal and installation of arm assembly.........................................932

Removal and installation of boom assembly........................................934

50 Disassembly and assembly..............................................................937

Cab and its attachments..............................................................938

Removal and installation of operator’s cab.......................................938

Removal and installation of operator’s cab glass (stuck glass)...................941

Removal and installation of front window assembly................................951

50 Disassembly and assembly..............................................................957

Electrical system....................................................................958

Removal and installation of air conditioner unit assembly........................958

Removal and installation of engine controller assembly...........................960

Removal and Installation of KOMTRAX terminal assembly............................962

Removal and installation of pump controller......................................962

Removal and installation of monitor assembly.....................................963

90 Diagrams and drawings.................................................................965

Hydraulic circuit diagram............................................................967

90 Diagrams and drawings.................................................................971

Electrical circuit diagram (1/5).....................................................973

Electrical circuit diagram (2/5).....................................................975

Electrical circuit diagram (3/5).....................................................977

Electrical circuit diagram (4/5).....................................................979

Electrical circuit diagram (5/5).....................................................981

Electrical circuit diagram for air conditioner.......................................983

PLEASE NOTE: ⦁ This is not a physical manual but a digital manual – meaning no physical copy will be couriered to you. The manual can be yours in the next 2 mins as once you make the payment, you will be directed to the download page IMMEDIATELY.

⦁ This is the same manual used by the dealers inorder to diagnose your vehicle of its faults.

⦁ Require some other service manual or have any queries: please WRITE to us at [email protected]