Fiat Hitachi D180 Crawler Dozer Service Repair Manual

FILE DETAILS:

Fiat Hitachi D180 Crawler Dozer Service Repair Manual

Language : English

Pages : 259

Downloadable : YES

Format : PDF

Size : 8.88 MB

DESCRIPTION:

Fiat Hitachi D180 Crawler Dozer Service Repair Manual

SAFETY RULES:

Do not allow unauthorised personnel to operate service or maintain this machine. Do not wear rings, wrist watches, jewellery, loose or hanging apparels, such as ties, torn clothing, scarves, unbuttoned or unzipped jackets that can catch on moving parts. Wear proper safety equipment as recommended for the job. Examples: hard hat, heavy gloves, ear protection, safety glasses or goggles, reflector vests, respirator. Consult your employer for specific safety equipment requirements.

- Keep operator’s compartment, stepping points, grabrails and handles clear of foreign objects, oil, grease, mud or snow accumulation to minimise the danger of slipping or stumbling. Clean mud or grease from shoes before attempting to mount or operate the machine. Do not jump on or off the machine. Keep two hands and one foot, or two feet and one hand in contact with step grab rails and handles at all times. Do not use controls or hoses as hand holds when climbing on or off machine. Hoses and controls are movable and do not provide a solid support.

- Also, controls may be inadvertently moved causing accidental machine or equipment movement. Never attempt to operate the machine or its tools from any position other than seated in the operator’s seat. Keep head, body, limbs, hands and feet inside operator’s compartment at all times, to reduce exposure to hazards outside the operator’s compartment.

- Be careful of slippery conditions on stepping points, hand rails, and on the ground. Wear safety boots or shoes that have a high slip resistant sole material. Do not leave the machine until it is completely stopped. Check the seat safety belt at least twice a year. If there are signs of wear or fraying or other signs of weakness that could lead to failure, replace it.

STARTING:

NEVER START NOR OPERATE AN UNSAFE MACHINE. Before operating a machine, always ensure that any unsafe condition has been satisfactorily remedied. Check brakes, steering and attachment controls before moving. Advise the proper maintenance authority of any malfunctioning part or system. Be sure all protective guards or panels are in place, and all safety devices provided are in place and in good operating conditions. Be sure exposed personnel in the area of operation are clear of the machine before moving it or its attachments.

- WALK COMPLETELY AROUND the machine before mounting. Sound horn. Before starting machine, check, adjust and lock the operator’s seat for maximum comfort and control of the machine. Fasten your seat belt (when provided). Obey all flag signals and signs. Due to the presence on the machine of flammable fluids, never check or fill fuel reservoirs or batteries near open flames, smoking materials or sparks. REMEMBER THAT STARTING FLUID IS FLAMMABLE.

- Follow strictly the recommendations printed on containers and in the Operation and Maintenance Manual. DO NOT PUNCTURE OR BURN CONTAINERS. Containers must be stored in fresh, well ventilated places, out of reach of unauthorised persons. Follow strictly the instructions provided by the Manufacturer. Never use these products near open flames, smoking materials or sparks.

OPERATION :

Do not run the engine of this machine in closed areas without proper ventilation to remove deadly exhaust gases. Roll Over Protective Structures are required on loaders, dozers, graders, excavators. NEVER OPERATE machines without ROPS. Make sure the Operator’s compartment is free of foreign objects, especially if not firmly secured. Never use the machine to transport objects, unless proper securing points are provided.

TABLE OF CONTENTS:

Fiat Hitachi D180 Crawler Dozer Service Repair Manual

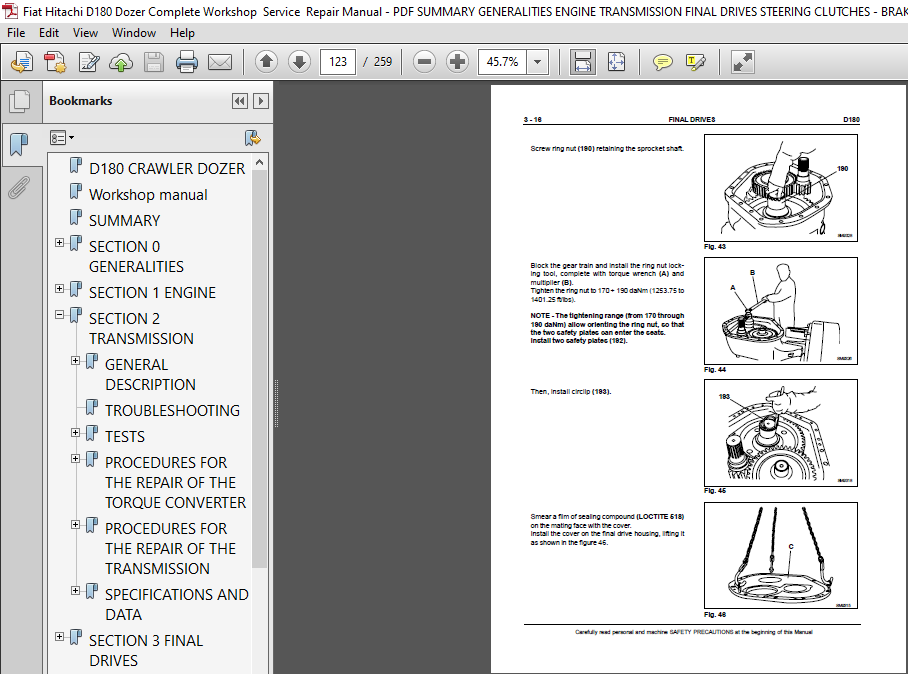

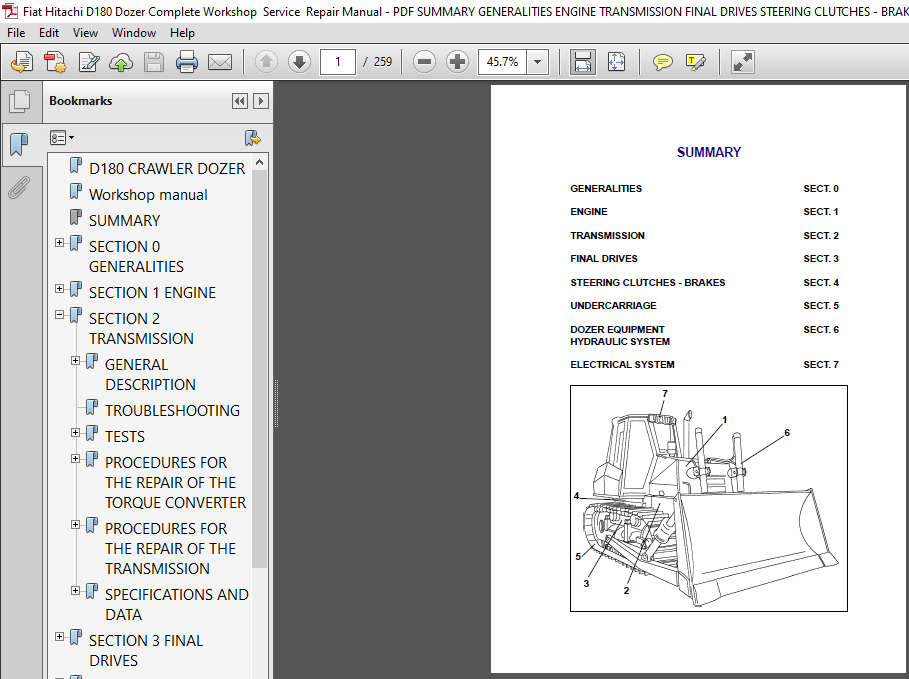

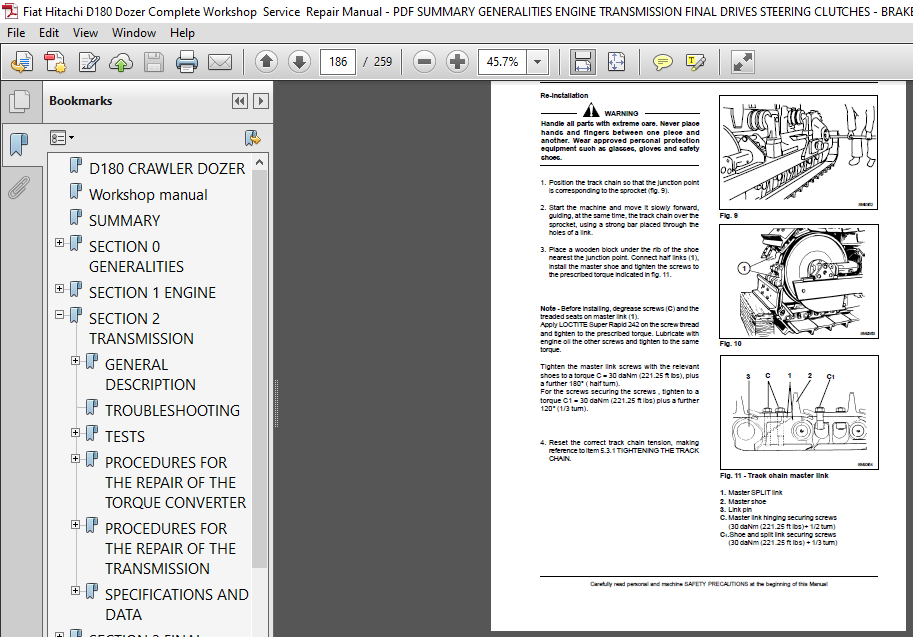

D180 CRAWLER DOZER........................................................ 0 Workshop manual........................................................... 0 SUMMARY................................................................... 1 SECTION 0 GENERALITIES.................................................... 2 SAFETY RULES.......................................................... 3 TECHNICAL DATA TABLES................................................. 11 GENERAL INSTRUCTIONS.................................................. 24 TROUBLESHOOTING....................................................... 29 UNITS OF MEASURE...................................................... 30 CLASSIFICATION OF STANDARD COMPONENTS................................. 30 TABLE OF TIGHTENING TORQUES........................................... 32 SECTION 1 ENGINE.......................................................... 33 GENERAL SPECIFICATIONS................................................ 34 SERIES "C" ENGINE DATA................................................ 36 DIAGRAMS OF SERIES "C" ENGINE......................................... 39 MOUNTING OF ENGINE ON FRAME........................................... 42 SECTION 2 TRANSMISSION.................................................... 43 GENERAL DESCRIPTION................................................... 44 TRANSMISSION TORQUE CONVERTER HYDRAULIC DIAGRAM................... 0 Transmission housing.............................................. 0 TROUBLESHOOTING....................................................... 47 TESTS................................................................. 51 Torque converter stall test....................................... 0 TRANSMISSION GEARSHIFTING ELECTRIC CONTROL VALVE.................. 0 PROCEDURES FOR THE REPAIR OF THE TORQUE CONVERTER..................... 66 REMOVAL........................................................... 0 RE-INSTALLATION................................................... 0 DISASSEMBLY....................................................... 0 REASSEMBLY........................................................ 0 PROCEDURES FOR THE REPAIR OF THE TRANSMISSION......................... 66 REMOVAL........................................................... 0 RE-INSTALLATION................................................... 0 DISASSEMBLY....................................................... 0 OVERHAUL OF THE FORWARD SPEED CLUTCH.............................. 0 OVERHAUL OF THE 3 rd SPEED........................................ 0 OVERHAUL OF THE REV SPEED CLUTCH.................................. 0 MODULATING VALVES (Disassembly / Assembly)........................ 0 PRESSURE RELIEF VALVE (Disassembly / Assembly).................... 0 SPECIFICATIONS AND DATA............................................... 97 GENERAL DATA...................................................... 0 TIGHTENING TORQUES (TORQUE CONVERTER)............................. 0 TRANSMISSION HOUSING.............................................. 0 TRANSMISSION DATA................................................. 0 TRANSMISSION CLUTCH DISC.......................................... 0 LUBE OIL PRESSURE RELIEF VALVE.................................... 0 FORWARD REVERSE MODULATING VALVES................................. 0 TRANSMISSION PRESSURE RELIEF VALVE AND TORQUE CONVERTER SAFETY.... 0 TORQUE CONVERTER / TRANSMISSION FEEDING PUMP...................... 0 OIL FILTERS....................................................... 0 SECTION 3 FINAL DRIVES....................................................108 GENERAL DESCRIPTION...................................................109 Final drive.......................................................110 REPAIR PROCEDURES.....................................................112 Disassembly.......................................................114 Pulling the housing cover.........................................116 Driven gear.......................................................117 Driving gear shaft................................................117 Description of installation of front seals (long life)............118 Final drive (removal / disassembly)...............................112 Final drive (assembly)............................................119 SPECIFICATIONS AND DATA...............................................127 Final drive shaft and bearing fittings............................127 BEARING INSTALLATION SPECIFICATIONS AND DATA......................128 SECTION 4 BRAKES AND STEERING CLUTCHES....................................129 GENERAL DESCRIPTION OF THE CIRCUIT.................................... 0 BRAKES AND STEERING CLUTCHES SYSTEM HYDRAULIC DIAGRAM............. 0 MAIN COMPONENTS OF THE HYDRAULIC SYSTEM........................... 0 REAR TRANSMISSION (transmission side section)..................... 0 TROUBLESHOOTING....................................................... 0 DIAGNOSIS ON THE DISPLAY.......................................... 0 TESTS................................................................. 0 PRESSURE TEST OF THE BRAKES AND STEERING CLUTCH CIRCUIT........... 0 BRAKE PEDAL ADJUSTMENT............................................ 0 BRAKE SYSTEM PRESSURE TEST (with brake pedal)..................... 0 FEEDING VALVE TEST AND SETTING.................................... 0 CALIBRATION OF BRAKES/STEERING CLUTCH LEVERS...................... 0 REPAIR PROCEDURES Brake pedal valve................................... 0 STEERING CLUTCH AND BRAKE......................................... 0 BRAKES AND STEERING CLUTCHES...................................... 0 BEVEL GEAR UNIT................................................... 0 BEVEL GEAR........................................................ 0 PROCEDURE FOR THE SETTING OF THE PINION BEARINGS PRE-LOAD......... 0 PROCEDURE FOR THE SETTING OF THE BEVEL GEAR UNIT.................. 0 SPECIFICATIONS AND DATA............................................... 0 BEVEL GEAR REDUCTION UNIT (General data / dimensions)............. 0 STEERING CLUTCHES................................................. 0 BRAKE PEDAL VALVE................................................. 0 SECTION 5 UNDERCARRIAGE...................................................177 GENERAL DESCRIPTION...................................................178 GENERALITIES......................................................178 MAIN COMPONENTS...................................................179 TROUBLESHOOTING.......................................................182 INSPECTIONS...........................................................183 INSPECTION AND ADJUSTMENT OF TRACK CHAINS.........................183 SETTING OF THE TRACK TENSIONER PRESSURE RELIEF VALVE..............184 REPAIR PROCEDURES.....................................................185 TRACK CHAIN (removal / installation)..............................185 REPLACING A DAMAGED LINK AND RE-INSTALLATION......................187 IDLER.............................................................189 TRACK CHAIN SUPPORT ROLLERS (removal/installation/overhaul).......192 TRACK CHAIN BOTTOM ROLLERS (removal / installation / overhaul)....194 SPECIFICATIONS AND DATA...............................................198 IDLER.............................................................198 SPECIFICATIONS AND DATA...............................................199 SPROCKETS.........................................................199 TRACK CHAINS......................................................199 BOTTOM ROLLERS....................................................200 SUPPORT ROLLERS...................................................201 TRACK TENSIONER DEVICE............................................202 FRONT CROSS-MEMBER PIVOTS (*).....................................203 FRONT CROSS-MEMBER PIVOTS.........................................203 WEAR LIMITS.......................................................207 SECTION 6 DOZING EQUIPMENT HYDRAULIC SYSTEM...............................209 GENERAL DESCRIPTION...................................................210 OPERATION OF THE HYDRAULIC SYSTEM.................................210 DIAGRAM OF DOZING EQUIPMENT HYDRAULIC SYSTEM......................213 DOZER EQUIPMENT HYDRAULIC SYSTEM DIAGRAM..........................212 TROUBLESHOOTING.......................................................214 TESTS.................................................................218 USE OF THE FLOW METER.............................................218 FLOW TEST IN SINGLE CIRCUITS......................................218 PUMP FLOW TEST....................................................219 REPAIR PROCEDURES.....................................................221 HYDRAULIC OIL RESERVOIR (Removal / installation)..................221 Equipment hydraulic pump..........................................223 Hydraulic control valve...........................................224 Montage du godet..................................................225 SPECIFICATIONS AND DAT................................................226 Hydraulic control valve...........................................226 Supply hydraulic pump.............................................227 Blade lifting cylinder ball joint.................................228 Blade lifting control cylinder....................................229 Blade tilt control cylinder (Bulldozer version)...................230 Blade tilt control cylinder (Angledozer version)..................231 Ripper cylinder...................................................232 Blade push arms and rods..........................................233 Frame and rods....................................................234 Ripper linkage....................................................235 SECTION 7 ELECTRICAL SYSTEM...............................................237 SAFETY RULES..........................................................238 ELECTRICAL SYSTEM.....................................................239 FUSES.................................................................241 LINK" FUSES AND COLD STARTING.........................................242 MAIN SWITCH...........................................................243 ENGINE STARTING SWITCH................................................243 BACK-UP ALARM.........................................................244 STARTER MOTOR.........................................................244 INSTRUMENT PANEL / MONITOR............................................245 MONITOR SENDERS.......................................................248 BUZZER................................................................254 RELAY - DIODES - DIVERTER BOX GROUP...................................255 MAIN CONNECTORS 19 - 21 - 23 WAYS.....................................258

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the SAME MANUAL used by the dealerships to diagnose your vehicle

- No waiting for couriers / posts as this is a PDF manual and you can download it within 2 minutes time once you make the payment.

- Your payment is all safe and the delivery of the manual is INSTANT – You will be taken to the DOWNLOAD PAGE.

- So have no hesitations whatsoever and write to us about any queries you may have : heydownloadss @gmail.com