Case IH Tractor Magnum 180, Magnum 200, Magnum 220, Magnum 240 Operator’s Manual

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

- This manual contains important information about the safe operation, adjustment and routine maintenance of your Magnum™ series tractor. The manual is divided into 10 chapters as outlined in the table of contents. Refer to the index at the end of this manual for locating specific items about your tractor. Do NOT operate or permit anyone to operate or service this machine until you or the other persons have read this manual.

- Use only trained operators who have demonstrated the ability to operate and service this machine correctly and safely. This Operator’s Manual is to be stored in the manual compartment behind the operator’s seat in the vehicle. Make sure this manual is in good condition.

- Contact your dealer to obtain additional manuals. Your CASE IH dealer will instruct you in the general operation of your new equipment. Your dealer’s staff of factory- trained service technicians will be glad to answer any questions that may arise regarding the operation of your machine. They will also provide any after-sales service you may need, and genuine CASE IH parts, your guarantee of quality and match.

TABLE OF CONTENTS:

Case IH Tractor Magnum 180, Magnum 200, Magnum 220, Magnum 240 Operator’s Manual_48158585

1 GENERAL INFORMATION

Note to the Owner 1-1

Engine tampering 1-1

Tractor intended use1-2

Tractors with 50 km/h (30 mph) transmissions 1-2

Electro-Magnetic Compatibility (EMC)1-3

ISOBUS certification1-3

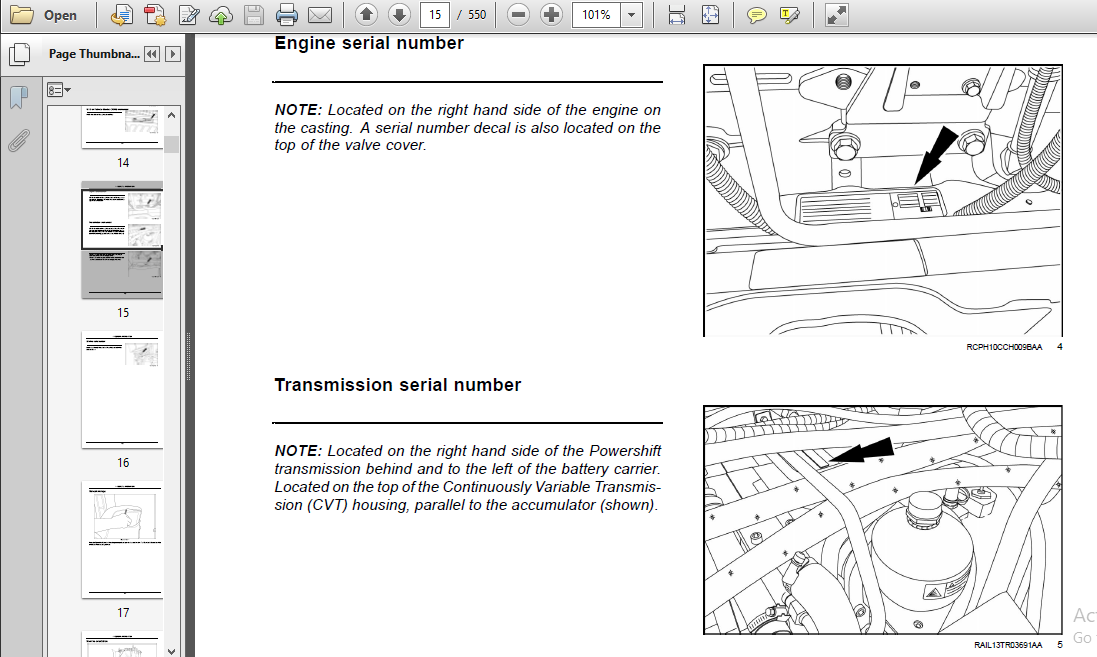

Product identification1-4

Manual storage1-7

Machine orientation 1-8

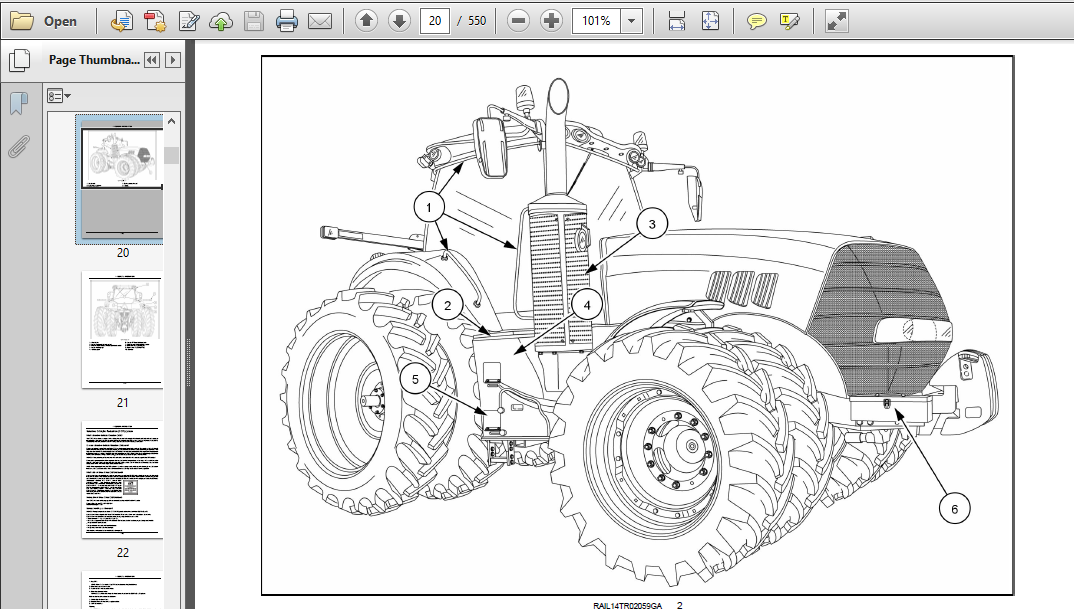

Component identification1-9

Selective Catalytic Reduction (SCR) system 1-12

2 SAFETY INFORMATION

Safety rules and signal word definitions 2-1

Safety rules – General2-2

Safety rules – General maintenance safety 2-3

Safety rules – Wheels and tires 2-4

Safety rules – Driving on public roads and general transportation safety 2-4

Safety rules – Fire and explosion prevention2-5

Safety rules – General battery safety 2-5

Safety rules – Hydraulic system safety2-5

Safety rules – Instructional seat safety2-6

Safety rules – Operator presence system 2-6

Safety rules – Power Take-Off (PTO) 2-7

Safety rules – Reflectors and warning lights2-7

Safety rules – Seat belts2-7

Safety rules – Roll Over Protective Structure (ROPS)2-7

Safety rules – Cab protection 2-9

Safety rules – Air conditioning system2-9

Safety rules – Personal Protective Equipment (PPE) 2-9

Safety rules – Do Not Operate tag2-9

Safety rules – Hazardous chemicals2-9

Safety rules – Utility safety 2-10

Safety rules – Electrical storm safety 2-10

Safety rules – Mounting and dismounting2-10

Safety rules – Working at heights2-11

Safety rules – Lifting and overhead loads2-11

Safety rules – Implements, tools and trailers 2-11

Safety rules – Roll over and tip over 2-12

Proposition 652-13

Ecology and the environment2-13

Safety signs2-14

Selective Catalytic Reduction (SCR) decals 2-22

Global warming potential 2-24

3 CONTROLS AND INSTRUMENTS

ACCESS TO OPERATOR’S PLATFORM

Tractor access 3-1

Lower step3-3

OPERATOR’S SEAT

Control identification3-4

INSTRUCTOR’S SEAT

Overview3-8

FORWARD CONTROLS

Steering column 3-9

Front console 3-12

Pedal controls3-14

RIGHT-HAND SIDE CONTROLS

Armrest console3-16

Multi function handle 3-17

Minimum/maximum throttles 3-22

Control panel 3-23

Remote valve controls 3-32

Joystick 3-33

Armrest compartment3-34

Adjusting the armrest console3-36

REARWARD CONTROLS

Fender console 3-37

Automatic temperature controls3-40

Automatic Temperature Control (ATC) system 3-43

Ventilation3-44

OVERHEAD CONTROLS

Interior lamps 3-46

EXTERIOR CONTROLS

Rear fender 3-47

INSTRUMENT CLUSTER

Overview 3-48

Gauges 3-48

Status and warning icons3-49

Upper display 3-52

Lower display 3-54

Keypad 3-55

Adjust and configure menus 3-56

Rear tire radius chart 3-63

Performance features3-64

4 OPERATING INSTRUCTIONS

COMMISSIONING THE UNIT

Before starting the engine 4-1

STARTING THE UNIT

Normal engine starting4-4

Cold starting aids4-6

Cold temperature operation 4-7

STOPPING THE UNIT

Stopping the engine 4-9

MOVING THE UNIT

FULL POWERSHIFT TRANSMISSION4-11

Powershift transmission4-11

Inching pedal and throttle4-12

Transmission controls4-13

Upper display 4-15

Manual transmission operation 4-16

Automatic Productivity Management (APM™) 4-18

Automatic Productivity Management (APM) field4-19

Automatic Productivity Management (APM) road4-22

Shuttle memory4-25

Transmission errors and calibration4-26

Creeper gears4-27

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)4-28

Introduction 4-28

Continuously Variable Transmission (CVT) brake, pedal and throttle operation 4-29

Continuously Variable Transmission (CVT) controls 4-34

Continuously Variable Transmission (CVT) upper display 4-39

Continuously Variable Transmission (CVT) operation 4-40

Driving the Continuously Variable Transmission (CVT)4-43

Continuously Variable Transmission (CVT) error codes 4-48

POWERSHIFT AND CVT TRANSMISSIONS 4-49

Selective Catalytic Reduction (SCR) system 4-49

Engine idling or full catalyst messages 4-60

Mechanical Front Drive (MFD) 4-62

Differential lock system 4-64

Suspended axle4-66

Cab suspension, if equipped 4-68

Engine power management4-69

Ride control4-71

Constant engine speed 4-72

Electronic end of row system 4-75

PARKING THE UNIT

Automatic park lock4-85

5 TRANSPORT OPERATIONS

ROAD TRANSPORT

Tractor warning lamps and Slow Moving Vehicle (SMV) symbol 5-1

Wide transport marker light 5-3

Tractor warning lamps 5-5

Safe transport speed5-6

Implement warning lamps and Slow Moving Vehicle (SMV) symbol5-7

Safety chain 5-7

SHIPPING TRANSPORT

Securing the tractor for shipping5-8

RECOVERY TRANSPORT

Safety rules5-9

6 WORKING OPERATIONS

GENERAL INFORMATION

Before operating the vehicle6-1

Guidelines 6-2

REAR POWER TAKE-OFF (PTO)

Safety rules6-3

Connecting the Power Take-Off (PTO)6-6

Power Take-Off (PTO) operation6-9

Two speed Power Take-Off (PTO) systems6-12

Auto Power Take-Off (PTO) operation 6-13

Power Take-Off (PTO) fender switch operation6-15

THREE-POINT HITCH

Connecting three-point hitch implements6-16

Three-point hitch adjustments6-17

Hitch quick coupler – Category III/IIIN6-23

Hitch controls and settings 6-28

Draft control6-33

Position and ride control 6-36

DRAWBARS AND TOWING ATTACHMENTS

Safety rules 6-38

Adjusting the drawbar6-39

HYDRAULIC TRAILER BRAKES

Trailer brake connections6-42

AUXILIARY CONNECTIONS

Auxiliary power and lighting6-43

Cab power connections6-44

Radar connection6-45

Implement ISOBUS connector 6-46

HYDRAULIC REMOTE CONTROL VALVES

Valve couplers and connections6-47

Flow capacity 6-53

Transport lock6-55

Transport lock6-55

Operating the controls6-57

Remote valve display screens 6-62

Joystick operation6-65

BALLASTING THE TRACTOR

Guidelines6-70

Tire load and inflation charts 6-83

Weights, cast metal6-95

Wheel slip and power hop performance6-101

MECHANICAL FRONT DRIVE (MFD) AXLES

Tire combinations and tread positions6-103

Toe-in setting – Mechanical Front Drive (MFD) axles 6-110

Steering and oscillation stops 6-111

Tread and fender settings – Class 40 fixed front axles 6-113

Tread and fender settings – Class 475 suspended front axles 6-118

Front wheel narrow fenders – Narrow fenders, fixed or suspended – Class 40 or 475

axles6-127

Front wheel wide fenders – Wide fenders, fixed or suspended – Class 40 or 475 axles

6-132

REAR AXLE

Rear wheel installation6-137

Rear wheel tread settings 6-143

Dual wheel setup for 20/22 row spacing6-147

7 MAINTENANCE

GENERAL INFORMATION

Safety rules7-1

Maintenance guidelines 7-2

Dealer service and parts7-2

Opening the hood 7-3

Closing the hood7-5

Filling the fuel tank7-7

Draining the Diesel Exhaust Fluid (DEF)/AdBlue® tank7-9

Filling the Diesel Exhaust Fluid (DEF)/AdBlue® tank7-10

Battery access and service 7-12

Tire and rim service7-14

Tractor jacking points 7-16

Capacities7-18

Consumables – Engine oil 7-19

Consumables – Front axle oil7-20

Consumables – Transmission/hydraulic system 7-20

Consumables – Diesel fuel 7-20

Consumables – Biodiesel fuels 7-21

Consumables – Diesel Exhaust Fluid (DEF)/AdBlue® 7-23

Consumables – Organic Acid Technology (OAT) coolant7-25

Maintenance summary decal 7-27

Maintenance planning

Maintenance chart 7-28

At warning message display

Air filter service icon/message 7-30

Fuel filter water separator7-34

Hydraulic oil filter 7-35

Every 10 hours or daily

Engine coolant level7-36

Engine oil level 7-37

Windshield washer fluid level7-38

First 50 hours

Dealer performed service7-39

Every 50 hours

Coolers and condenser7-40

Cab air filter7-42

Grease fittings7-45

Tire pressure 7-49

Every 300 hours

Fan belt 7-50

Transmission oil level7-51

Mechanical Front Drive (MFD) gearbox – Class 475 suspended axle only 7-52

Every 600 hours

Engine oil and filter 7-53

Diesel Exhaust Fluid (DEF)/AdBlue® in-line filter7-55

Hydraulic filter(s) 7-57

TwinFlow oil filter 7-59

Engine primary air filter 7-60

Engine air intake hoses7-63

Fuel filters7-65

Differential and planetary oil7-67

Every 1200 hours or annually

Cab air filter7-68

Transmission cartridge filter7-70

Rear axle bearing7-74

Transmission oil7-75

Differential and planetary oil7-79

Mechanical Front Drive (MFD) gearbox – Class 475 suspended axle only 7-83

Battery terminals 7-84

Every 1200 hours or two years

Engine secondary air filter 7-85

Engine valve adjustment 7-88

Blowby filter7-88

Every 3600 hours

Diesel Exhaust Fluid (DEF)/AdBlue® supply module filter 7-89

Every 36 months

Air conditioning system 7-92

Every 4000 hours or every four years

Engine coolant 7-93

As required

Wheel bolt torque7-96

Pre-filter and water trap – if equipped7-97

Fuel tank vent filter 7-99

Diesel Exhaust Fluid (DEF)/AdBlue® tank filler screen 7-100

Diesel Exhaust Fluid (DEF)/AdBlue® in tank filter7-102

Fan belt7-103

Remote valve collection bottle7-107

Cab fabric and carpet 7-108

Tractor exterior7-109

Seat belt 7-110

Fuse and relay locations

Electrical system – Component identification7-111

STORAGE

Preparing for storage7-117

Removing from storage 7-119

ELECTRICAL SYSTEM

Radio or audio system7-120

Battery removal and installation 7-121

Recharging the battery7-123

Headlight7-124

Roof warning light 7-125

Fender tail light and warning light 7-126

Work light7-127

LED work lights7-128

High intensity work light 7-129

Wide transport marker light 7-130

Rotating beacon light7-131

Interior light7-132

8 TROUBLESHOOTING

ALARM(S)

Display warnings8-1

Automatic engine shutdown 8-8

Fault reporting 8-9

SYMPTOM(S)

Engine symptoms8-10

Transmission symptoms 8-12

Hydraulic symptoms8-13

Hitch symptoms8-14

Brake symptoms 8-15

Cab environment symptoms 8-16

Electrical power system symptoms8-17

9 SPECIFICATIONS

Engine – General specification9-1

Transmission – General specification9-2

Operating speeds 9-5

Maximum angle (tilt) of operation 9-7

Vehicle dimensions and shipping weight9-8

Maximum operating weight 9-10

10 ACCESSORIES

Farming system displays 10-1

Chemical tank mounting 10-2

Loader connection and operation10-5

General accessories 10-6

11 FORMS AND DECLARATIONS

FILE DETAILS:

Case IH Tractor Magnum 180, Magnum 200, Magnum 220, Magnum 240 Operator’s Manual_48158585

Size : 55.2 MB

Format : PDF

Language : English

Number of Pages : 550 pages

Brand: Case IH

Type of machine: Tractor

Type of document: Operator’s Manual

Model: Magnum™ 180, Magnum™ 200, Magnum™ 220, Magnum™ 240

Part No: 48158585

PLEASE NOTE:

- This is the same manual used by the DEALERSHIPS to SERVICE your vehicle.

- The manual can be all yours – Once payment is complete, you will be taken to the download page from where you can download the manual. All in 2-5 minutes time!!

- Need any other service / repair / parts manual, please feel free to contact us at heydownloadss @gmail.com . We may surprise you with a nice offer