Case IH Tractor Diesel Engine and Fuel Systems for 300 & 400 series Service Manual

FILE DETAILS:

Case IH Tractor Diesel Engine and Fuel Systems for 300 & 400 series Service Manual_GSS1427B

Size : 74.3 MB

Format : PDF

Language : English

Number of Pages : 462 pages

Brand: Case IH

Type of machine: Tractor

Type of document: Service Manual

Model: Diesel Engine and Fuel Systems for 300 & 400 series

Part No: GSS1427B

DESCRIPTION:

- Duo to a continuous program of rescurch and development, same procedures, specifications and parts may be altered in a constant oifort to improve our products.

- When changes and improvements are made in our products, periodic revisions may be Inade to this manual to keep lt up-to-date. It Is suggested that customers contact their dealer for information on the Inter revision.

1. To prevent injury, do not allow children or bystanders around the machine while it is being adjusted anlfls‘r serviced.

2. Always use safety stands in conjunction with hydraulic iacks or hoists. Do not rely on the jack or hoist to carry the load, they could fail.

3. Articulated Tractors — Always use the frame lock pin when servicing the tractor in the area of the hinged or pivot point of the frame. The lock pln must be in place when making adjust- ments with the engine running. The lock pin prevents accidental pivoting of the frame. Always remove the lock pin and store correctly before attempting to steer the tractor.

4. Always wear safety glasses when using a hammer, chisel or other tools that may cause chips to fly.

5. Keep work area organized and clean. Wipe up all or spills of any kind. Keep tools and parts off of the floor. Eliminate the possibility of a fall which could result in a serious injury.

6. Be sure to reinstall safety devices, guards or shields after adjusting and/or servicing the machine. Also, replace missing or damaged safety and/or instruction decals.

7. After servicing, be sure all tools, parts, or servicing equipment are removed from the machine.

8. When splitting tractors, or disassembling machines, be sure to use safety stands and adequate supports to prevent tipping or rollover.

9. Use a safety catch on all hoist hooks. Do not take a chance, the load could slip off of the hook.

10. When using an acetylene torch always wear welding goggles and gloves. Keep a “charged” fire extinguisher within reach. Be sure the ace- tylene and oxygen tanks are separated by a metal shield and are chained to the cart. Do not weld or heat areas near fuel tanks or fuel lines and utilize proper shielding around hydraulic lines.

IMAGES:

VIDEO PREVIEW:

TABLE OF CONTENTS:

Case IH Tractor Diesel Engine and Fuel Systems for 300 & 400 series Service Manual

GENERAL CONTENTS

Safe Work Rules

Standard Torque Data for Nuts and Bolts

Torque Values for Hose Clamps

Inch—Metric Conversion Tables

Special Service Tools Required

Service Information System (S.I.S.)

General Shop Practices for Engine Overhaul

Sealing Compound Use

SECTION 1 – ENGINE

Special Nut and Bolt Torque Data

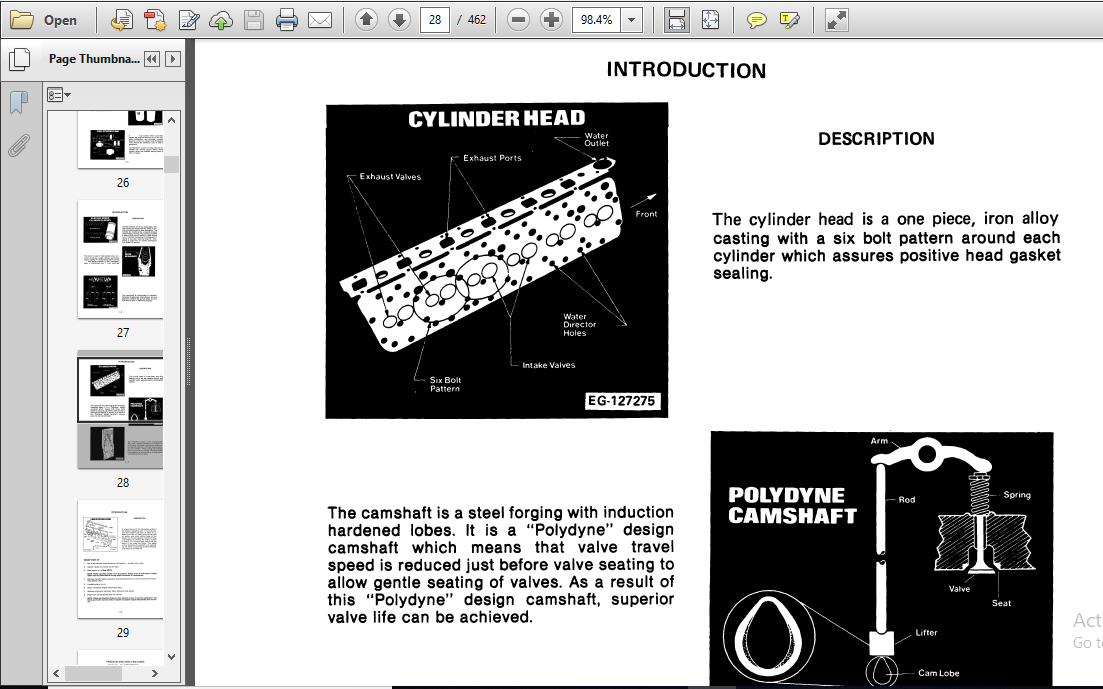

Introduction

Problem and Analysis Guide

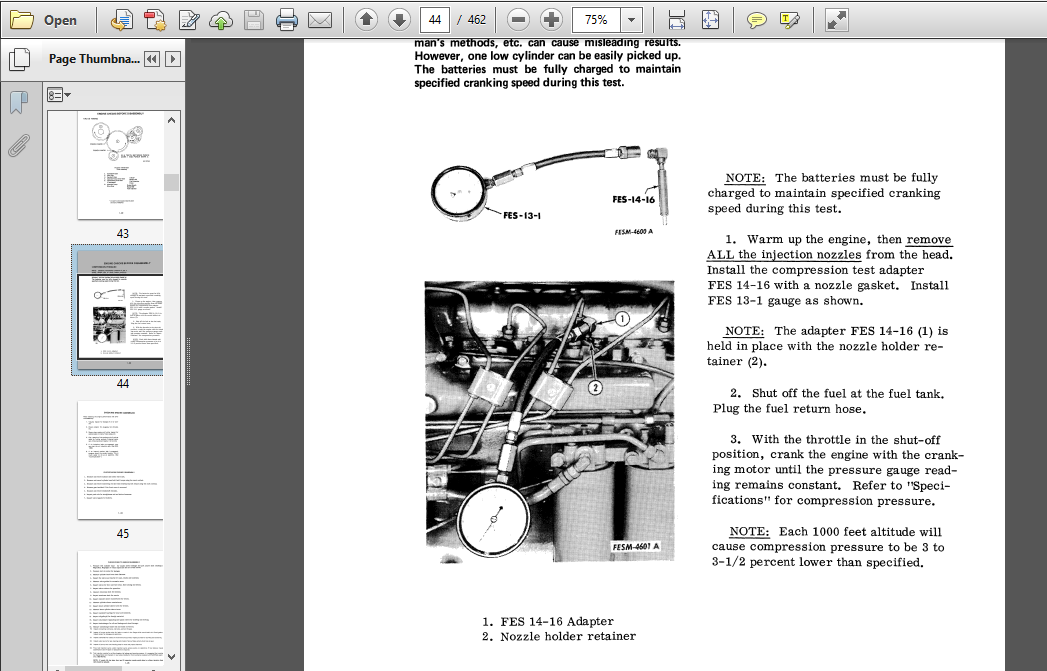

Engine Checks Before Disassembly

Checking Engine Assembled and Checks During Engine Disassembly

Checks Prior to Engine Reassembly

Checks Prior to Engine Startup and Engine Start-up

Specifications

Mounting Engine on Stand

Manifolds

Cylinder Head & Valves

Valve Train – Camshaft, Tappets and Push Rods

Timing Gear Train and Front Cover

Connecting Rods, Pistons, Rings and Sleeves

Crankshaft, Main Bearings, Flywheel and Crankcase

Lubrication System

Cooling System

SECTION 2 – FUEL SYSTEM – U.T.D.S. Model 100 (AMBAC) Injection Pump

Dimensional Tolerances

Explanation of Pump Type Designation

Pump Assemblies

General Pump Information and Pump Features

Removal of Pump

Pump Overhaul

Troubleshooting

Flow Bench Testing

Installation of Pump

Checks and Adjustments

ROBERT BOSCH MODEL MW INJECTION PUMP

General Pump Information

Plunger Positions During Injection Cycle

External Injection Pump Controls

RSV Governor and Aneroid

Optional Method of Installation

Adjustments

On-Engine Injection Pump Repairs

Checking Supply Pump Pressure and/or Inlet Restriction

Checking the Aneroid Diaphragm for Leaks

Trouble Finding & Testing

NOZZLES

Description and Operation

Nozzle Identification

General

SECTION 3 – TURBOCHARGER

Specifications

Description

General Maintenance and Cleaning Procedure

Inspection Before Removal

Turbocharger Testing

Removal and Servicing of Air Induction System After a Turbocharger Compressor Failure

Airesearch Turbocharger

Schwitzer Turbocharger

Installation

PLEASE NOTE:

⦁ This is the same manual used by the dealers to diagnose and troubleshoot your vehicle

⦁ You will be directed to the download page as soon as the purchase is completed. The whole payment and downloading process will take anywhere between 2-5 minutes

⦁ Need any other service / repair / parts manual, please feel free to contact [email protected] . We still have 50,000 manuals unlisted