Case IH Tractor 2142,2152,2162 Draper Header CA20 Comb Adapter Service Manual (84175530)

FILE DETAILS:

Case IH Tractor 2142,2152,2162 Draper Header CA20 Comb Adapter Service Manual_84175530

Size : 41.3 MB

Format : PDF

Language : English

Number of Pages : 325 pages

Brand: Case IH

Type of machine: Tractor

Type of document: Service Manual

Model: 2142,2152,2162

Part No: 84175530

DESCRIPTION:

This Service Manual contains important information about the working, adjustment, and repair of your Draper Header and Combine Adapter. Refer to the Table of Contents at the beginning of this manual to locate specific items about the machine. This Service Manual should be used in conjunction with the Draper Header Operator’s Manual. The Left and Right side of the Draper Header and Combine Adapter are the same as your Left and Right hand while seated in the Combine Operator’s seat facing forward in a normal field operation position.

SCREENSHOT OF THE MANUAL:

TABLE OF CONTENTS:

1 – GENERAL INFORMATION AND SAFETY 1

GENERAL INFORMATION 1

STANDARD BOLT TORQUE 2

U S STANDARD 2

METRIC 3

METRIC TORQUE FOR ALUMINUM COMPONENTS 3

HYDRAULIC FITTINGS 4

STEEL HYDRAULIC FITTINGS 5

PRODUCT IDENTIFICATION NUMBERS 6

ENVIRONMENT 7

DISASSEMBLY, DECOMMISSIONING OR SCRAPPING THE MACHINE 7

PLASTIC AND RESIN PARTS 7

SAFETY DECALS 7

LUBRICATION AND MAINTENANCE CHART 8

OIL CAPACITIES 9

GENERAL SAFETY INFORMATION 10

SAFETY RULES 10

SERVICE AREA, FIRE EXTINGUISHER, FIRST AID KIT 13

PERSONAL SAFETY 14

DO NOT OPERATE TAG 15

COMBINE BALLAST 15

TRANSPORTATION SAFETY 16

TIRE SAFETY 17

MAINTENANCE SAFETY 18

DRIVESHAFT SAFETY 19

COMBINE FEEDER SAFETY LOCK 20

2300 / 2500 SERIES COMBINE 20

AFX8010, AXIAL-FLOW® 7010, 8010, 7120, 8120 AND 9120 21

AXIAL-FLOW® 5088, 6088 AND 7088 22

REEL SAFETY LOCK 23

FIRE OR EXPLOSION PREVENTION 24

2 – TROUBLESHOOTING 25

TROUBLESHOOTING 25

3 – GENERAL PROCEDURES 41

TAPER LOCK HUB 41

HOW IT WORKS 41

REMOVAL AND INSTALLATION 41

LOCK COLLAR 44

HOW IT WORKS 44

REMOVAL AND INSTALLATION 44

UNIVERSAL JOINT 45

HOW IT WORKS 45

REBUILDING THE UNIVERSAL JOINT 45

GUARDS 49

HOW IT WORKS 49

POINTED GUARD HEADER 50

DOUBLE KNIFE HEADERS – POINTED GUARDS 51

DOUBLE KNIFE HEADERS – FORGED STUB GUARDS 52

IMPORTANT GUARD INFORMATION 53

GUARD ADJUSTMENTS 53

4 – KNIFE DRIVE

KNIFE DRIVE SYSTEM 55

SINGLE KNIFE 55

DOUBLE KNIFE 56

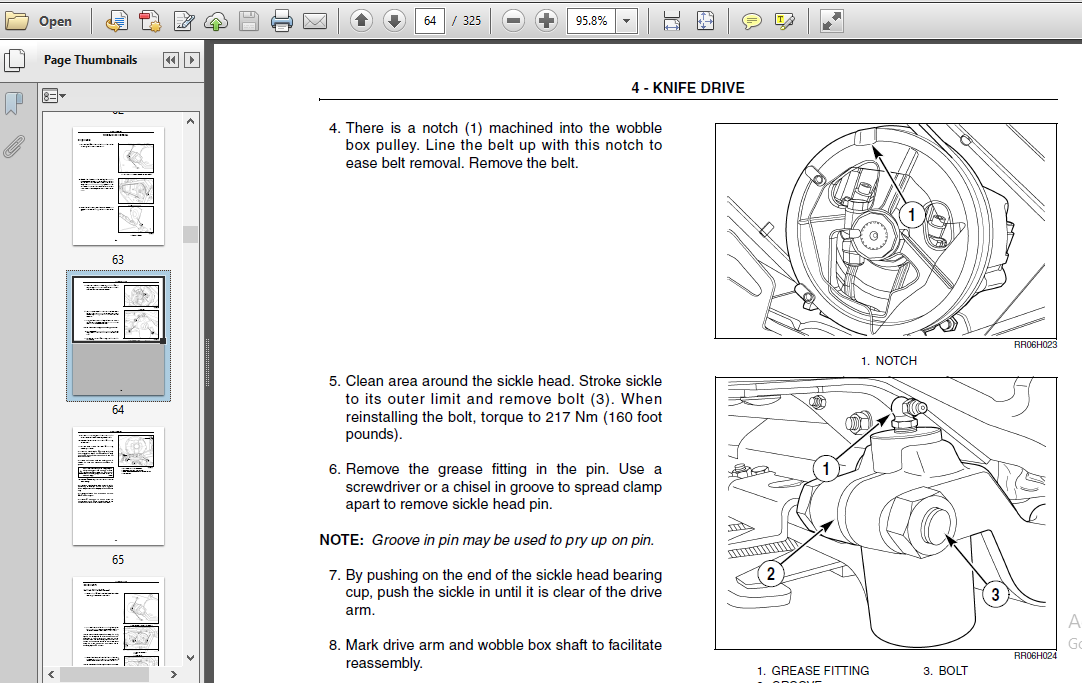

WOBBLE BOX REMOVAL 58

SINGLE KNIFE 58

DOUBLE KNIFE 61

RIGHT SIDE WOBBLE BOX REMOVAL 64

DOUBLE KNIFE DRIVE TIMING 66

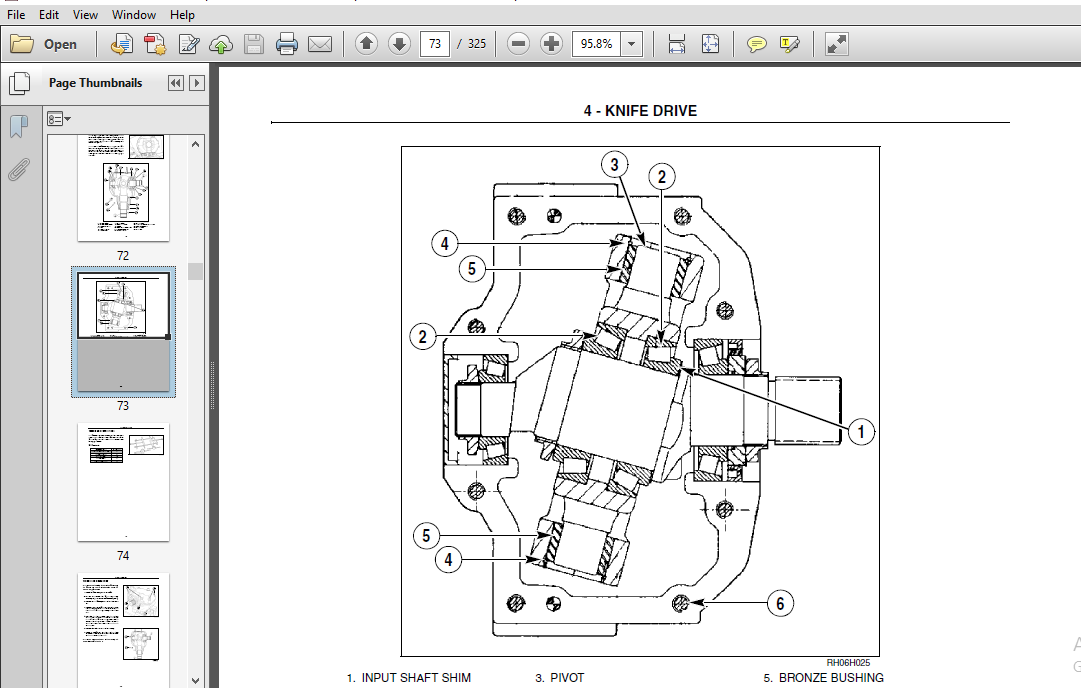

KNIFE DRIVE WOBBLE BOX 67

WOBBLE BOX REBUILD TOOLS 69

WOBBLE BOX DISASSEMBLY 70

WOBBLE BOX ASSEMBLY 77

WOBBLE BOX INSTALLATION 88

5 – ADAPTER DRIVE

ADAPTER GEARBOX 91

PREPARE TO REMOVE GEARBOX 91

INSTALL GEARBOX 92

DISASSEMBLY 93

ASSEMBLY 97

FEED AUGER 105

DRUM AUGER INTERNAL REPAIR – PRIOR TO P I N Y9ZN 110

DRUM AUGER INTERNAL REPAIR – P I N Y9ZN AND AFTER 112

ASSEMBLY 118

FEED AUGER INSTALLATION 122

6 – DRAPER DRIVE

DRAPER DRIVE SYSTEM 123

HYDRAULIC SCHEMATIC 123

DRAPER DECK 124

IDLER ROLLER BEARING REPLACEMENT 128

DRIVE ROLLER BEARING REPLACEMENT 130

ADAPTER FEED DECK 133

ADAPTER IDLER ROLLER BEARING REPLACEMENT 137

FEED DRAPER DRIVE ROLLER BEARING REPLACEMENT 141

7 – REEL DRIVE

REEL DRIVE SYSTEM 145

REEL CONFIGURATION 147

SINGLE SPAN REEL REMOVAL 148

DOUBLE REEL (SPLIT) REMOVAL 151

REEL DRIVE REPAIR 157

SINGLE REEL DRIVE DISASSEMBLY 157

SINGLE REEL ASSEMBLY 162

SPLIT REEL DRIVE DISASSEMBLY 166

DOUBLE REEL DRIVE ASSEMBLY 171

8 – HYDRAULIC SYSTEM

COMBINE ADAPTER HYDRAULICS 177

HOW IT WORKS 177

FORWARD OPERATION 178

FEED DRAPER RELIEF 179

SIDE DRAPER RELIEF 179

SCHEMATICS 180

REVERSE OPERATION 186

RELIEF PRESSURE 186

SCHEMATICS 187

COMBINE ADAPTER HYDRAULIC PRESSURE TEST 190

COMBINED REEL FORE / AFT HEADER TILT BLOCK 192

THREE SOLENOID DESIGN SELECTOR VALVE 192

HYDRAFORCE SELECTOR VALVE 192

SELECTOR VALVE SCHEMATIC 193

TWO SOLENOID DESIGN SELECTOR VALVE 199

HYDRAFORCE SELECTOR VALVE 199

SELECTOR VALVE SCHEMATIC 200

COMBINE DATA – OUTPUT SHAFT SPEEDS ON HEADER 201

HYDRAULIC TESTING AND REPAIR 202

MINIMUM TEST EQUIPMENT 202

CHECKING PISTON PUMP (KNIFE DRIVE) FLOW AND COMPENSATOR PRESSURE 203

CHECKING RELIEF AND FLOW – FEED DRAPER FORWARD 208

CHECKING RELIEF AND FLOW – SIDE DRAPERS FORWARD 210

SETTING THE UNLOADER VALVE “V7” 211

TESTING GEAR PUMP EFFICIENCY 212

CHECKING PUMP EFFICIENCY 213

TESTING PISTON PUMP EFFICIENCY 214

CHECKING PUMP EFFICIENCY 214

HYDRAULIC OIL SPECIFICATIONS 215

ADAPTER OIL TEMPERATURE 215

OIL CHANGE PROCEDURE 216

ADDING OIL TO RESERVOIR 218

REEL LIFT CYLINDERS 219

REEL LIFT THEORY 219

REEL DRIVE, LIFT AND FORE / AFT SCHEMATICS 220

DIAGNOSTIC TEST – STATIC 221

DIAGNOSTIC TEST – DYNAMIC 221

STATIC AND DYNAMIC TEST DIAGNOSTIC CHART 222

CYLINDER REPAIR 224

CENTER MASTER REEL LIFT CYLINDER 224

REEL LIFT SECONDARY MASTER LEFT CYLINDER 225

REEL LIFT SLAVE RIGHT CYLINDER 226

FORE / AFT CYLINDER 227

SINGLE REEL – REEL LIFT (LEFT) CYLINDER 228

SINGLE REEL – REEL LIFT (RIGHT) CYLINDER 229

FORE / AFT CYLINDER 230

DOUBLE REEL – CENTER MASTER REEL LIFT CYLINDER 231

DOUBLE REEL LIFT RIGHT CYLINDER 232

DOUBLE REEL LIFT LEFT CYLINDER 233

DOUBLE REEL FORE / AFT CYLINDER 234

HYDRAULIC MOTOR 235

SIDE DRAPERS 235

SIDE DRAPERS 242

DECK SHIFT 245

REEL 255

FEED DRAPER 265

MULTI-LINKS 274

9 – ELECTRICAL SYSTEM

ELECTRICAL HARNESSES 277

HEADER – GENERAL INFORMATION 277

LIGHTING 278

PRIOR TO P I N Y8ZN 278

P I N Y8ZN AND AFTER 284

ELECTRICAL HARNESS COMBINE SPECIFIC 290

TRANSPORT WIRING HARNESSES 293

SELECTOR VALVE 297

COMBINE ELECTRICAL HARNESS FOR THE SELECTOR VALVE 298

AUTOMATIC HEADER HEIGHT CONTROL (AHHC) 303

FLOAT OPTIMIZER 303

HOW IT WORKS 303

CALIBRATE 305

AUTOMATIC HEADER HEIGHT CONTROL (AHHC) TROUBLESHOOTING 306

FLOAT OPTIMIZER TROUBLESHOOTING 306

ADJUSTING THE SENSOR’S RANGE 306

POTENTIOMETER TROUBLESHOOTING 307

DIAGNOSTIC OF POTENTIOMETER 307

REEL SPEED 308

HOW IT WORKS 308

10 – FLEX LINKAGE

FLEX LINKAGE 309

HOW IT WORKS 309

DISASSEMBLY 310

ASSEMBLY 313

WING BALANCE 316

CUTTER BAR STRAIGHTNESS 318

CUTTER BAR STRINGING 318

11 – STRUCTURE

IMPACT REPAIRS 319

HOW IT WORKS 319

CUTTER BAR STRINGING 319

IMPACT REPAIR PARTS 320

VIDEO PREVIEW:

PLEASE NOTE:

⦁ This is the SAME MANUAL used by the dealerships to diagnose your vehicle

⦁ No waiting for couriers / posts as this is a PDF manual and you can download it within 2 minutes time once you make the payment.

⦁ Your payment is all safe and the delivery of the manual is INSTANT – You will be taken to the DOWNLOAD PAGE.

⦁ So have no hesitations whatsoever and write to us about any queries you may have : heydownloadss @gmail.com