Zetor Tractor Crystal 150 Crystal 160 Operator’s Manual – PDF DOWNLOAD

FILE DETAILS:

Zetor Tractor Crystal 150 Crystal 160 Operator’s Manual – PDF DOWNLOAD

Language : English

Pages : 182

Downloadable : Yes

File Type : PDF

Size:19.9 MB

DESCRIPTION:

Zetor Tractor Crystal 150 Crystal 160 Operator’s Manual – PDF DOWNLOAD

ZETOR

This Operator’s Manual for the Zetor tractors, which we are presenting to you will help you to become familiar with the operation and maintenance of your new tractor. Although many of you have rich experience with the operation of other tractors, please, read the information contained in this Operator’s Manual very carefully. In the Manual you will find a lot of new information and get a perfect overview of how to use the tractor with maximum efficiency during various kinds of work. If you observe the rules of tractor operation and maintenance and driving safety, your new tractor will become your reliable and long-term friend. The manufacturer of the tractor wishes you thousands of hours of satisfactory work.

ABOUT THIS MANUAL

- This manual has been prepared to assist you in following / adopting the correct procedure for running-in operation and maintenance of your new ZETOR Tractor. Your tractor has been designed and built to provide maximum performance, low fuel consumption and ease of use.

- To maintain the condition and ensure trouble-free performance, it is important that maintenance is performed at the recommended intervals as described in this manual. Read this Manual carefully and keep it in a convenient place for future reference. If at any time you require advice concerning your Tractor, do not hesitate to contact your Authorized ZETOR dealer / Distributor.

- He has trained personnel, genuine parts and necessary equipments to undertake all your service requirements. All data given in this book is subject to production variations.

- Dimensions & weight are approximate only and the illustrations do not necessarily show Tractors in standard condition. For exact information about any particular Tractor, please consult your ZETOR dealer / Distributor.

INTRODUCTION & DESCRIPTION

- Instructions and Description

- The word ‘tractor’ is derived from ‘traction’, which means towing. The tractor is required to tow or draw working equipment, an implement or a trailer that is attached to the body of the tractor by means of a suitable hitch. The tractor can also be used as a drivetrain, thanks to a power output called a PTO or a PTO shaft.

- These operating manual is prepared in accordance with the operating, maintenance and storage instructions for the relevant Zetor tractor model. The manual has been designed to help you better understand the maintenance and efficient operation of this machine.

- If you require any information not provided in this manual or require service from a trained mechanic, contact your local ZETOR TRACTORS a.s. dealer/distributor. Dealers/distributors are kept informed about the latest service procedures for tractors. They have original spare parts in stock and have full service support from the machine manufacturer. In this manual, the use of the terms LEFT, RIGHT, FRONT and REAR must be unified to avoid any confusion when following these instructions.

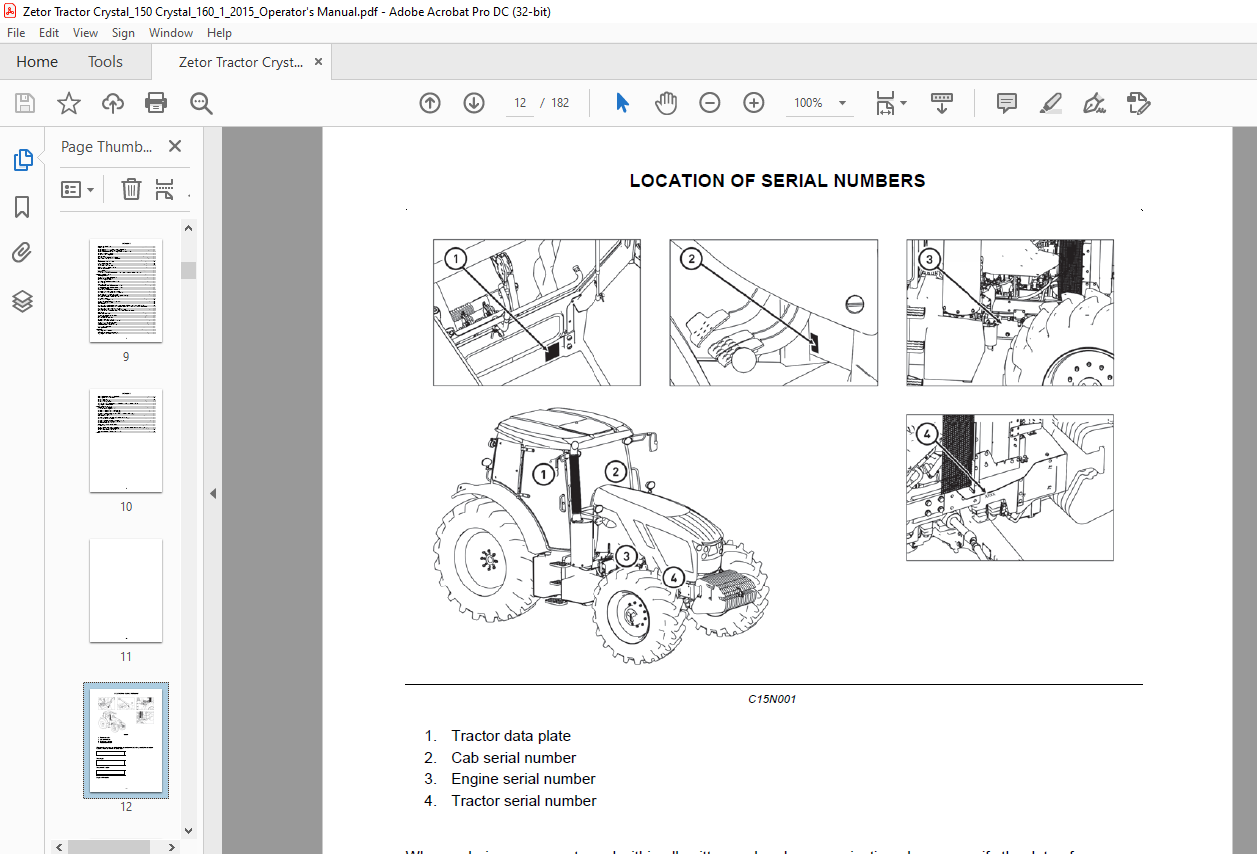

- LEFT and RIGHT means the left and right sides of the tractor when looking from the driver’s seat towards the front. The reference to FRONT means the end of the tractor radiator, while REAR means the end of the drawbar (see the picture). When ordering spare parts, always specify the tractor and engine serial numbers when ordering.

- This will make their delivery easier and faster and ensure that you receive the right spare parts for your particular tractor. The tractor’s serial number is stamped on a plate attached to the right side of the tractor (see the picture). For easy reference, we recommend you to write this number in the space reserved for the owner’s personal data.

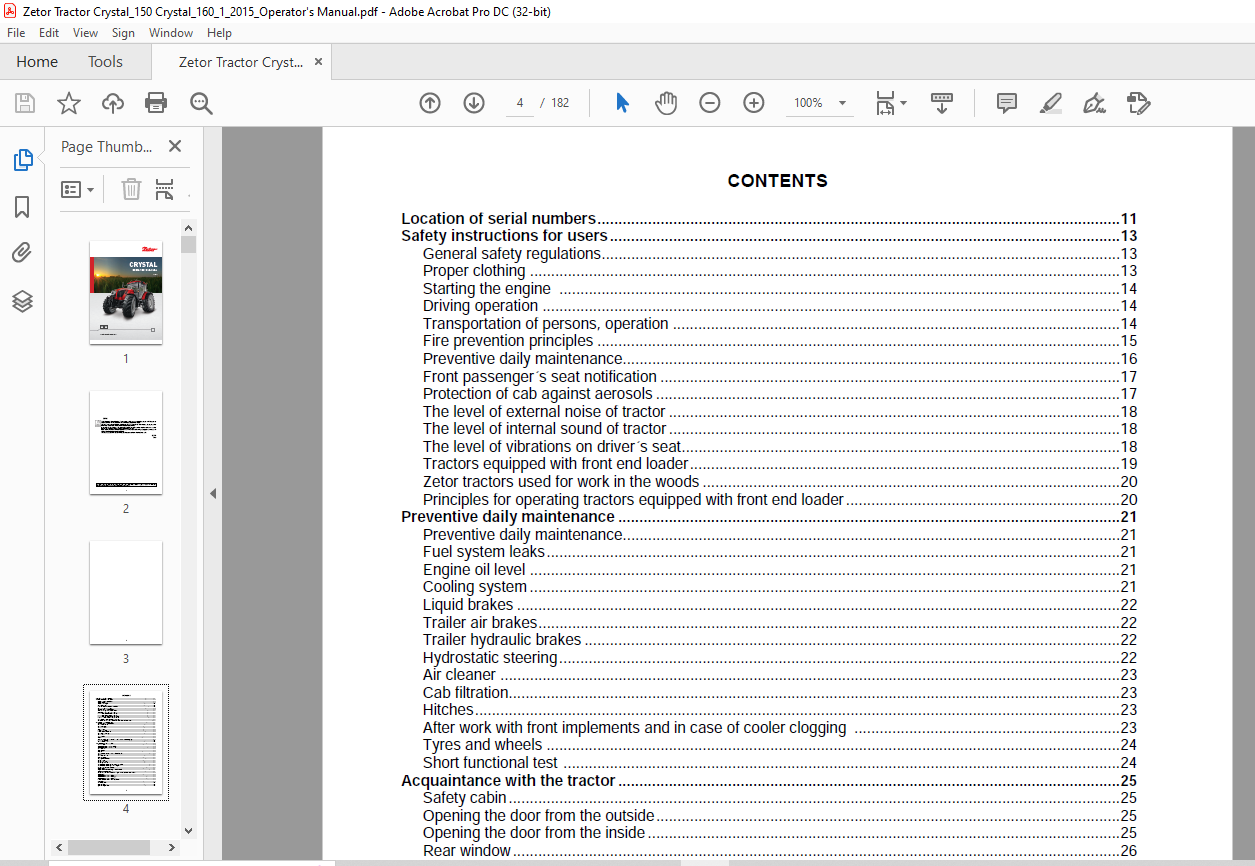

TABLE OF CONTENTS:

Zetor Tractor Crystal 150 Crystal 160 Operator’s Manual – PDF DOWNLOAD

Location of serial numbers 11

Safety instructions for users . 13

General safety regulations . 13

Proper clothing 13

Starting the engine . 14

Driving operation . 14

Transportation of persons, operation 14

Fire prevention principles 15

Preventive daily maintenance 16

Front passenger´s seat notification . 17

Protection of cab against aerosols 17

The level of external noise of tractor . 18

The level of internal sound of tractor . 18

The level of vibrations on driver´s seat 18

Tractors equipped with front end loader 19

Zetor tractors used for work in the woods . 20

Principles for operating tractors equipped with front end loader . 20

Preventive daily maintenance . 21

Preventive daily maintenance 21

Fuel system leaks 21

Engine oil level 21

Cooling system 21

Liquid brakes . 22

Trailer air brakes 22

Trailer hydraulic brakes . 22

Hydrostatic steering . 22

Air cleaner . 23

Cab filtration . 23

Hitches . 23

After work with front implements and in case of cooler clogging . 23

Tyres and wheels 24

Short functional test 24

Acquaintance with the tractor . 25

Safety cabin . 25

Opening the door from the outside 25

Opening the door from the inside 25

Rear window 26

Side window . 26

Hinged lid . 26

Adjustable screen and cover of the swing lid 26

Shelf . 27

Rear view mirrors 27

Internal lighting 27

Aggregation opening . 28

Driver´s seat 28

Driver’s seat Sears 29

Passenger´s seat . 29

Control panel on the right column of the cabin 30

Control panel on the right rear mudguard . 30

Panel of the instrument panel 30

Lights switch 31

Lights switch between the grill and the cabin 31

Switch of warning lights . 31

Direction lights, lower beam head lights, head lights and horn switches 32

Switch box . 32

Switch box key in the position (0) 32

Switch box key in the position (I) . 33

Switch box key in the position (II) 33

Tilting and protrusion of steering wheel . 33

Manual throttle . 33

Reversing lever 34

Gear shifting lever . 34

Gear shifting scheme . 34

CONTENTS

3

Pedals 34

Road and reduced speeds shifting lever . 35

PTO revolutions preselection lever . 35

Manual brake lever and coupling for semi-trailer control lever 35

Battery disconnector 36

Heating control panel, * air-condition 36

Heating valve control (A) . 36

Switch air-condition (C) . 37

Air circulation in cabin control (D) 37

Proper function of the heating and air-condition system . 37

Fast heating of the cabin area . 38

Fast cooling of the space of the cabin . 38

Operation of heating or air-condition with tractor´s work . 38

Immediately after cooling the cabin . 38

Air-condition and heating registers (A) 39

Front windshield (B) defrosting 39

*Air filter with active carbon . 40

Wiper and washer of the front window 40

Front wiper speed switch . 40

Rear window wiper 41

Windshield washer tank 41

Washer nozzle . 41

Fuel tank 42

Fuel tank drain plug . 42

Urea tank . 42

Dashboard . 43

Instrument panel – signal lamps . 43

Instrument panel – instruments 44

Instrument panel – buttons . 44

Display description 45

Change of the look of display 45

Display – change of display 45

Display – resetting data 49

Display – manual brake 50

Display – indicator of service inspection intervals 50

Exceeding the service interval . 50

Zeroing (reset) of the indicator of service inspection intervals 51

Error signalling . 51

Display – error messages . 52

Description of the display of error messages 52

Symbols of tractor nodes . 53

Display – service menu 53

Service menu . 53

Display – history of defects 54

Display – setting language mutation 54

Display – machined area 55

Machined area menu . 55

Machined area width . 55

Setting of the user-defined width of aggregation . 56

Machined area record 56

Display – setting and calibration . 57

Travel speed calibration . 58

Setting of steering sensors of the front axle 59

Setting of time 60

Instrument panel – warning 60

Replenish fuel 60

Add urea 61

High temperature of the cooling liquid . 61

Low level of the cooling liquid 61

High temperature of the engine oil 62

High air temperature in the engine air intake system 62

Water in the coarse filter of fuel . 63

High oil temperature in the gearbox 63

CONTENTS

4

Full pushing filter of the gearbox distributor 64

Full pushing filter of the hydraulics 64

System of additional treatment of exhaust gases . 65

System of additional treatment of exhaust gases (SCR) 65

Conditions for system SCR operation . 65

Urea (Aqueous Urea Solution AUS 32) . 65

Principles for safe handling of urea . 65

Limitation of the engine power and engine revolutions . 66

Indication of amount of urea in the tank 66

Long-term shutdown of tractor . 66

Repairs and maintenance of the system of additional treatment of exhaust gases 66

Driving operation 57

Before you start . 67

If you do not succeed in starting the engine 67

Non-permitted starting . 67

Starting the engine of the tractor . 68

Blocking of the start . 68

Immediately after start . 68

Engine heating . 69

Error signalling . 69

Indication of the limitation of the engine power and engine revolutions 69

Signalling errors in the system of additional treatment of exhaust gases . 70

Gear shifting 70

Reversing lever 70

Reversing lever position signalization . 71

Shifting road and reduced speeds . 71

Road and reducing speeds lever position signalization 71

Driver´s seat – safety switch 71

The principles of appropriate use of tractors . 72

The description of the system of travel clutches . 72

The way of controlling the travel clutch by 72

The differences in ways of controlling the travel clutch by 72

Interrupted sound signal 73

Dead start of the tractor . 73

Dead start of tractor in regular operation – automatic dead start function . 73

Dead start by means of automatic dead start function 73

Dead start of tractor in regular operation – clutch pedal 73

Dead start – using the clutch pedal 74

Change the direction of drive . 74

Change the direction of drive by means of reversing lever . 74

Change the direction of drive – using the clutch pedal 75

Gear shifting 75

Gear shifting – Using the clutch pedal . 75

Gear shifting – using the clutch control button on the head of gear shifting lever 75

Blocking the automatic dead start function 75

Three-gear torque multiplier 75

Signalization of multiplier function . 76

Increasing, decreasing the travel speed by two gears 76

Multiplier preselection switch . 76

Multiplier pre-selection signalization 76

Automatic multiplier shifting . 77

Front drive axle control 78

Driving with engaged front axle drive 78

Manual Front drive axle control . 78

Automatic front drive axle control 79

Axle lock control of rear and front axle 79

Automatic axle lock control of rear and front axle . 80

Suspension front drive axle . 80

Front drive axle suspension mode setting . 81

Height adjustment of the front part of the tractor . 81

Manual brake – signalization 82

Driving down the slope 82

Foot brakes 83

CONTENTS

5

Warning signalization of air pressured drop 83

One-hose and two-hose brakes 83

One-hose brakes . 83

Two-hose brakes . 84

Hydraulic brakes of trailers 84

Connecting and disconnecting quick couplings of trailer hydraulic brakes . 84

Stopping the tractor – manual brake 85

Stopping the engine . 85

Leaving the tractor . 85

Warning signalization of hydrostatic steering failure . 85

Limiting travel speed . 85

Running in the tractor 87

General principles of new tractor run-in in first 100 hours of operation 87

In first 10 hours of operation 87

From 100 hours of operation . 87

Transportation 89

CBM stage quick-adjusting hitch . 89

Height adjustment and disassembly of the CBM stage hitch 89

Automatic mouth of the CBM stage hitch 89

Modular system of hitches for trailers and semi-trailers 90

Swinging draw-bar console module 90

Swinging draw-bar console with a fixed pin module . 90

Console with a ø 80 ball module . 91

Hitch for a single-axle CBM semi-trailer 91

Drive of agricultural machinery . 95

Work with PTO shaft 95

Controlling the front and rear PTO shaft . 95

Rear PTO shaft revolutions preselection lever 95

Standard and economical independent revolutions of rear PTO shaft . 96

Dependent and independent rear PTO shaft revolutions 96

Facilitating connection of joint shaft of an aggregated machine to the tractor 97

Selection switch of rear PTO clutch revolutions (P.T.O.) 97

Replaceable end points of rear PTO shaft 98

Rear PTO switch . 98

Engaging rear PTO shaft – Independent revolutions . 99

Engagement of rear PTO shaft – dependent revolutions . 99

Automatic disengagement of PTO clutch 100

Setting automatic disengagement of PTO shaft clutch – display description 100

Automatic disengagement of PTO shaft clutch – return to basic setting . 100

Setting automatic disengagement of PTO shaft clutch . 101

Work with automatic disengagement of PTO shaft clutch .102

Front PTO shaft . 102

Front PTO shaft control . 103

Maximum transferred output 103

Drive of machines with greater inertia masses 104

Hydraulic system 105

Hydraulic system . 105

Hydraulic pump 105

Control elements placement 105

Outer hydraulic circuit 105

Connecting and disconnecting quick-couplers 106

Quick-couplings with drip collection 106

Hydraulic distributor of the outer hydraulic circuit 106

Description of the functions of individual positions of control levers of the hydraulic distributor 107

Rear outlets of the outer hydraulic circuit 107

Front outlets of the outer hydraulic circuit . 108

Connecting machines and implements to the outer hydraulic circuit . 108

Electro-hydraulic system . 109

Control element functions 109

Equipment ‘OFF’ 109

Blocking cancellation . 110

Quick sinking . 110

Transport of implements 111

CONTENTS

6

Stop position 111

Vibration compensator (damper) . 111

Limitation of the upper position of the three-point hitch 112

Lowering speed . 112

Free position 112

Setting the control of three-point hitch . 112

Manual setting of control of three-point hitch 113

Automatic control of three-point hitch 113

Using the rear control 114

External control buttons of the electro-hydraulic system . 114

Indication of EHR-B errors . 114

Description of signals of EHR-B electro-hydraulic system errors 115

Description of minor errors of the EHR-B electro-hydraulic system 116

Hitches . 117

Rear three-point hitch 117

Safety principles of working with the three-point hitch 117

Height adjustment of the lifting draw-bars . 118

Fixed and free position of the lower hydraulic draw-bars 118

Limiting draw-bars . 118

Automatic limiting draw-bars 119

*Lower draw-bars with CBM hooks . 119

Securing the lower draw-bars with CBM hooks . 119

Upper draw-bar 120

*Front three-point hitch 120

Adjusting the lowering rate of the front three-point hitch . 120

Controlling front three-point hitch 120

Hydraulic lock of the front three-point hitch . 121

Working and transport position of the front three-point hitch 121

Driving with agricultural machines attached to the front three-point hitch . 121

Wheel track change 123

Front wheels track of front drive axle in tractors equipped with non-removable discs 123

Toe-in of the wheels of the front driving axle . 123

Adjustment of toe-in of the wheels of the front driving axle . 124

Rear wheels wheel track . 125

Ballast weights 127

*Rear wheel weights 127

Bottom weights 127

*Front weights 127

*Weight of the front three-point hitch . 128

Valve for filling tyre tubes with liquid . 128

Procedure of draining liquid from the tyres 129

Antifreeze solution for tyre filling 129

Electric installation . 131

Basic service information . 131

Accumulator battery . 131

Battery disconnector 132

Accumulator battery maintenance . 132

Alternator . 133

Alternator maintenance . 133

Electric installation overload . 133

Fuse panel . 134

Checking the adjustment of the front grill headlights 136

Adjusting the front grill headlights . 136

Checking the adjustment of the cab roof headlights . 137

List of lamps . 138

Tractor maintenance 139

Steps performed daily before the start of work 139

Steps performed every 50 hours of work 139

Steps performed every 100 hours of work 139

Steps performed every 500 hours of work 139

Steps performed outside the interval of 500 hours of work . 139

Filling and filter replacement 140

ZETOR Service Fillings . 141

Motor Oils 141

Specification of Oil for Tractor Transmission Devices . 141

Specification of Oil for the Front Driving Axle 141

Other Recommended Service Fillings Tested on Zetor Tractors 142

Oil to gear systems of tractors . 142

Oil for the front driving axle 142

Front PTO oil . 142

Hydraulic brake liquid for the tractors 143

Liquid for the cooling system of the tractors 143

Fuel 143

Plastic lubricant for the tractor . 144

Tractor greasing scheme 144

Solid front drive axle 144

Suspension front drive axle . 145

Hitch for a single-axle semi-trailer . 145

Front three-point hitch . 145

Three-point hitch 146

Hitch mouth for a trailer . 146

Technical maintenance of the tractors after a general overhaul of the main groups . 146

Maintenance instructions 147

Opening the hood 147

Checking the oil level in the engine . 147

Draining oil from the engine . 148

Filling the engine with oil . 148

Replacing full-continuous motor oil filter 149

Fuel Filtering 149

Raw Fuel Filter Clearing 150

Cartridge Replacement in the Raw Fuel Filter 150

Cartridge Replacement in the Fine Fuel Filter . 151

Fuel system venting . 151

Dry air cleaner maintenance instructions . 152

Recovery of the mainair cleaner element . 152

Replacing the safety element of the air cleaner . 152

Reassembly of the air cleaner elements 152

Bleeding the hydraulic circuit of the hydrostatic steering . 153

Replacing the hydrostatic steering hoses . 153

Replacing coolant . 153

Checking the oil in gearbox 154

Check and replacement of oil in gear box . 154

Draining and checking holes 154

After draining oil 154

Replacement of the transmission oil cleaner element with hydraulic pump suction filter 154

Insertion piece replacement of the oil cleaner with delivery filter of the gearbox switchboard . 155

Replacement of filter element of urea filter 155

Lubrication and filling points of the front driving axle . 155

Filling, inspection and drain opening of oil of the front wheel reducers . 156

Front PTO . 156

Brake fluid replacement . 156

Carbon filter installation instructions 156

Cleaning the heating filters 157

*Air filter with active carbon 157

Air-conditioning maintenance . 157

Draining condensate from the air reservoir 158

Checking the air systems for leaks . 158

Working pressure of air brakes . 158

Maintenance and treatment of tyres . 159

Tyres for driving wheels 161

Storing the tractor 161

Adjustment 163

Adjusting valve clearance 163

Flat belt drive tension of accessories 163

Adjusting the play of the brake pedals . 163

Bleeding the brake system of the tractor 163

Bleeding the rear brake system 164

Foot brake check 164

Foot brake adjustment 165

Parking brake adjustment . 165

Adjustment of the lifting draw-bars of the hitch for a single-axle semi-trailer 165

Adjusting the bowden cable . 165

Main technical parameters . 167

Main tractor’s parameters (mm) 167

Technical data of engines 167

Permitted maximum load of front axle (kg) 168

Permitted maximum load of rear axle (kg) 168

Permitted maximum weight of set ‘tractor + mounted machine’ (kg) 168

Manoeuvrability condition 168

Front tires steerability 169

Change of the load-bearing capacity of the front tyres (%) . 169

Bearing capacity of rear tires . 170

Change of the load capacity of the rear tyres (%) . 170

Permitted combinations of wheels for tractors 170

Performance on rear PTO shaft 170

Lifting force of the three-point hitch . 171

Tensile force 171

Speed of tractor with engine revolutions of 2 100 rpm and parameter of rear wheels (km/h) 172

Independent rear pto shaft revolutions 173

Speed of the Zuidberg front PTO 174

Clearance-circle and turning circle diameter . 174

Index . 175

IMAGES PREVIEW OF THE MANUAL:

VIDEO PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the SAME MANUAL used by the dealerships to diagnose your vehicle

- No waiting for couriers / posts as this is a PDF manual and you can download it within 2 minutes time once you make the payment.

- Your payment is all safe and the delivery of the manual is INSTANT – You will be taken to the DOWNLOAD PAGE.

- So have no hesitations whatsoever and write to us about any queries you may have : heydownloadss @gmail.com

S.M