Sea doo 180 Challenger 2008 2009 Workshop Service Manual

FILE DETAILS:

- LANGUAGE:ENGLISH

- PAGES:780

- FILE TYPE:PDF

- DOWNLOADABLE:YES

DESCRIPTION:

- This manual has been prepared as a guide to correctly service and repair 2008 SEA-DOO® watercraft as describe in the model list in the INTRODUCTION. This edition was primarily published to be used by watercraft mechanical technicians who are already familiar with all service procedures re lating to BRP made watercraft.

- Mechanical technicians should attend training courses given by BRPTI. Please note that the instructions will apply only if proper hand tools and special service tools are used. This Shop Manual uses technical terms which may be slightly different from the ones used in the PARTS CATALOG.

- It is understood that this manual may be translated into another language. In the event of any discrepancy, the Engl ish version shall prevail. The content depicts parts and/or procedures applicable to the particular product at time of writing. SER~ VICE and WARRANTY BULLETINS may be published to Jpdate the content of this manual.

- Make sure to read and understand these. In addition, the sole purpose of the illustrations throughout the manual, is to assist identification of the general configuration of the parts. They are not to be interpreted as technical drawings or exact replicas of the parts.

- The use of BRP parts is most strongly recommended when considering replacement of any component. Dealer and/or distributor assistance should be sought in case of doubt. The engines and the corresponding components identifed in this document should not be utilized on product(s) other than those mentioned in this document

IMAGES:

VIDEO PREVIEW:

TABLE OF CONTENTS:

Sea doo 180 Challenger 2008 2009 Workshop Service Manual

INTRODUCTION IX

GENERAL INFORMATION JX

VEHICLE INFORMATION X

WORKING ON WATERCRAFT X

ENGINE EMISSIONS INFORMATION XI

TIGHTENING TORQUE XII

SELF-LOCKING FASTEl\IERS PROCEDURE XIII

LOCTITE® APPLICATION PROCEDURE XIII

MANUAL INFORMATION XVI

01 MAINTENANCE

01 – MAINTENANCE CHART 1

02 – PRESEASON PREPARATION 3

03 – STORAGE PROCEDURE 5

PROCEDURES 5

PROPULSION SYSTEM 5

FUEL SYSTEM 5

ENGINE 6

ELECTRICAL SYSTEM 7

VEHICLE 7

04 – SPECIAL PROCEDURES 9

TOWING THE WATERCRAFT IN WATER 9

SUBMERGED WATERCRAFT 9

WATER-FLOODED ENGINE 9

CAPSIZED WATERCRAFT 12

02 TROUBLESHOOTING

01 – TECHNICAL GUIDELINES 13

ENGINE 13

ELECTRICAL SYSTEM 19

PROPULSION 20

STEERING SYSTEM 20

02 – DIAGNOSTIC FLOW CHART 23

FUEL SYSTEM 23

03 ENGINE

01 – ENGINE REMOVAL/INSTALLATION 25

GENERAL 25

PROCEDURES 25

ENGINE 25

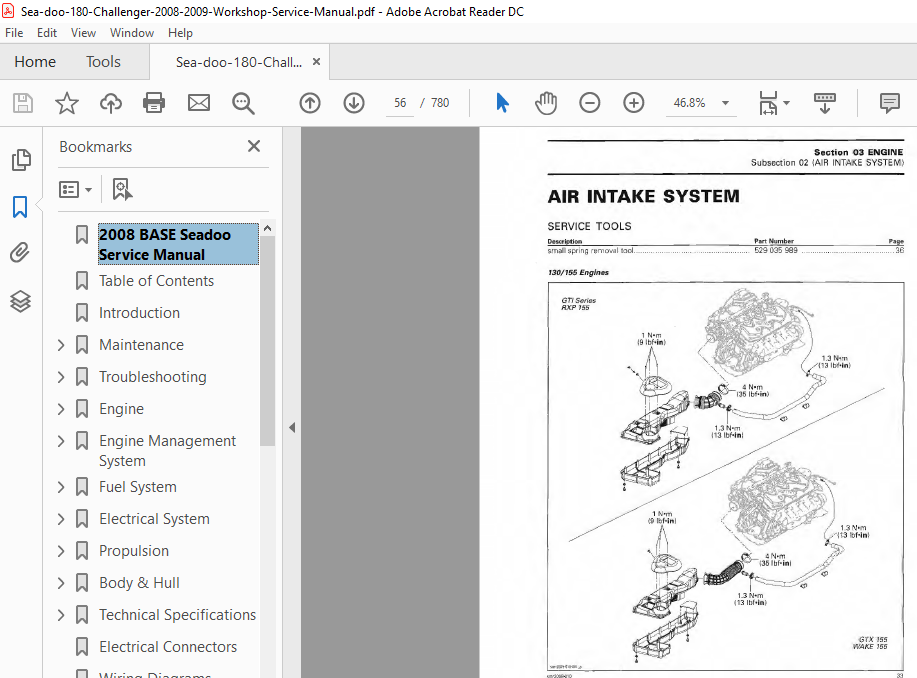

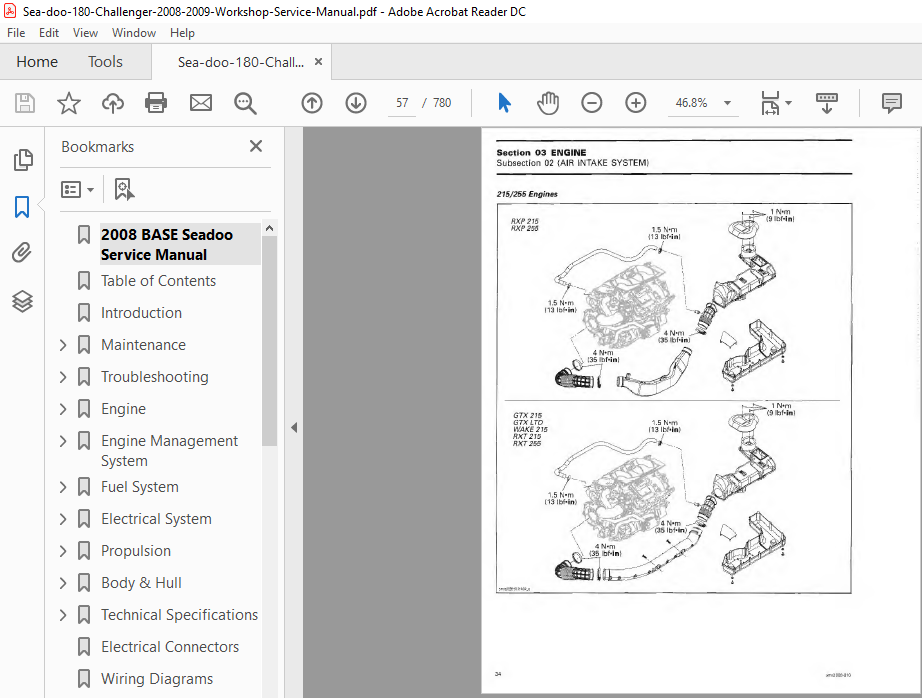

02 – AIR INTAKE SYSTEM 33

GENERAL 35

PROCEDURES 35

AIR INTAKE SILENCER 35

03 – INTAKE MANIFOLD/INTERCOOLER 37

GENERAL 41

PROCEDURES 41

INTAKE MANIFOLD 41

INTERCOOLER 46

04 – INTERCOOLER (255 ENGINE) 49

GENERAL 51

MAINTENANCE 51

PROCEDURES 51

INTERCOOLER 51

TABLE OF CONTENTS

II

INTERCOOLER SUPPORT 54

05 – SUPERCHARGER 55

GENERAL 57

INSPECTION 57

SUPERCHARGER INLET CLEANLI NESS 57

SUPERCHARGER CLUTCH SLIPPING MOMENT (ON ENGINE) 58

SUPERCHARGER CLUTCH SLI PPING MOMENT (BENCH TEST) 59

PROCEDURES 60

SUPERCHARGER 60

06 – EXHAUST SYSTEM 71

EXHAUST COOLING SYSTEM 73

GENERAL 75

SYSTEM DESCRIPTION 75

MAINTENANCE 76

EXHAUST SYSTEM FLUSH ING 76

PROCEDURES 77

MUFFLER 77

EXHAUST PIPE 80

EXHAUST MANIFOLD 81

RESONATOR 83

EXHAUST OUTLET 85

EXHAUST GAS TEMPERATURE SENSOR (EGTSJ 85

07 – PTO HOUSING/MAGNETO 87

GENERAL 89

PROCEDURES 89

PTO HOUSING 89

PTO SEAL 95

PTO COUPLING 95

STARTER DRIVE BEARING 96

STATOR 97

ROTOR AND TRIGG ER WHEEL 100

RING GEAR 101

STARTE R DRIVE 102

08- LUBRICATION SYSTEM 105

GENERAL 109

MAINTENANCE 109

ENGINE OIL 109

OIL FILTER 111

INSPECTION 112

ENGINE OIL PRESSURE 112

PROCEDURES 113

PTO OIL STRAINER 113

SUCTION PUMP OIL STRAINER 114

ENGINE OIL PRESSURE REGULATOR 116

OIL PRESSURE PUMP 117

OIL SUCTION PUMP 120

OIL SPRAY JET 123

OIL SEPARATOR COVER 124

TOPS VALVE 125

OIL COOLER 126

09 – COOLING SYSTEM , 129

GENERAL 134

CIRCUIT 134

TECHNICAL SPECIFICATIONS 134

INSPECTION 134

PRESSURE CAP 134

TABLE OF CONTENTS

HOSES AND CLAMPS 134

COOLING SYSTEM LEAK TEST 135

MAINTENANCE 135

COOLANT REPLACEMENT 135

PROCEDURES 137

CLAMPS 137

WATER PUMP HOUSING 138

WATER PUMP IMPEL L E~ 139

THERMOSTAT 140

ROTARY SEAL 140

10 – CYLINDER HEAD 143

GENERAL 145

PROCEDURES 145

EXHAUST MANIFOLD 145

CYLINDER HEAD COVER 146

SPARK PLUG TUBES 146

ROCKER ARMS 147

CAMSHAFT TIMING GEAR 149

CYLINDER HEAD 151

CAMSHAFT 152

VALVE SPRINGS 153

VALVES 1 55

VALVE GUIDES 158

11 – CYLINDER BLOCK 161

GENERAL 164

PROCEDURES 164

TIMING CHAIN 164

CHAIN TENSIONER 164

PISTONS/CONNECTING RODS 165

PISTON RINGS 170

CRANKSHAFT 171

BALANCER SHAFT 175

CYLINDER BLOCK 178

04 ENGINE MANAGEMENT SYSTEM

01 – OVERVIEW 183

SYSTEM DESCRIPTION 185

CONTROLLER AREA NETWORK (CAN) 185

ENGINE CONTROL MODULE (ECM) 185

POWER DISTRIBUTION 186

02- COMMUNICATION TOOLS/B U D S SOFTWARE 189

COMMUNICATION TOOLS 189

MPI 189

MPl-2 191

B U D S SOFTWA RE 194

03 – MONITORING SYSTEM/FAULT CODES 197

MONITORING SYSTEM 197

FAULT CODES 199

SPECIFIC FAULT CODES 199

FAULT CODE TABLE 201

05 FUEL SYSTEM

01 – ELECTRONIC FUEL INJECTION (EFI) 215

GENERAL 215

SYSTEM DESCRIPTION 215

DEUTSCH CONNECTOR INFORMATION 218

Ill

TABLE OF CONTENTS

KOSTAL CONNECTOR (ECM) INFORMATION 220

GENERAL RECOMMENDATIONS 224

BASIC ADJUSTIVIENTS 228

IDLE SPEED 228

CLOSED THROTTLE AND IDLE ACTUATOR RESET 228

IGNITION TIMING 229

REPAIR PROCEDURES 229

ENGINE CONTROL M ODULE IECM) 229

FUEL INJECTOR 232

THROTTLE BODY 235

THROTTLE POSITION SENSOR (TPS) 237

IDLE AIR CONTROL VALVE (IACV) 239

CRANKSHAFT POSITION SENSOR (CPS) 240

CAMSHAFT POSITION SENSOR (CAPS) 242

MANIFOLD AIR TEMPERATURE SENSOR (MATS) 244

COOLANT TEMPERATURE SENSOR (CTS) 245

MANIFOLD AIR PRESSURE SENSOR (MAPS) 246

EXHAUST GAS TEMPERATURE SENSOR IEGTS) 247

KNOCK SENSOR (KS) 248

OIL PRESSURE SENSOR (OPSl 249

TOPS SWITCH 250

02 – FUEL TANK/FUEL PUMP 255

GENERAL 257

SYSTEM DESCRIPTION 257

INSPECTION 260

FUEL TANK LEAK TEST 260

FUEL SYSTEM HIGH PRESSURE LEAK TEST 262

FUEL PUMP PRESSURE TEST 263

PROCEDURES 264

FUEL HOSES AND OETIKER CLAMPS 264

FUEL FILTER 265

FUEL TANK 265

FUEL PUMP 268

FUEL LEVEL SENSOR 272

06 ELECTRICAL SYSTEM

IV

01 – IGNITION SYSTEM 277

GENERAL 277

IGNITION SYSTEM DESCRIPTION 277

TROUBLESHOOTING 277

IGNITION SYSTEM TESTING 277

PROCEDURES 278

IGNITION COILS 278

SPARK PLUGS 282

02 – CHARGING SYSTEM 285

GENERAL 285

SYSTEM DESCRIPTION 285

PROCEDURES : 286

VOLTAGE REGULATOR/RECTIFIER 286

BATTERY 289

03 – STARTING SYSTEM 297

GENERAL •• 297

TROUBLESHOOTING 297

PROCEDURES 298

STARTER SOLENOID FUSE 298

ENGINE START/STOP SWITCH 298

TABLE OF CONTENTS

STARTER SOLENOID 301

STARTER 305

04- DIGITALLY ENCODED SECURITY SYSTEM (DESS) 309

GENERAL 309

PROCEDURES 310

DESS KEY 310

BEEPER 311

DESS POST 311

05 – GAUGE/FUSES 317

GENERAL 317

PROCEDURES 318

FUSES 318

MAIN RELAY , 321

INFORMATION CENTER 323

PROCEDURES 326

INFORMATION CENTER 326

FUEL LEVEL SENSOR 334

WATER TEMPERATURE SENSOR 337

COMPASS 338

SPEED SENSOR 339

DEPTH GAUGE 341

BEEPER 342

07 PROPULSION

01 – JET PUMP 347

GENERAL 350

INSPECTION 350

IMPELLER CONDITION

IMPELLER/WEAR RING CLEARANCE

LEAK TEST

PROCEDURES

SACRIFICIAL ANODE

VENTURI

JET PUMP HOUSING

IMPELLER COVER

IMPELLER

WEAR RING

IMPELLER SHAFT AND BEARING

02 – DRIVE SYSTEM

GENERAL

MAINTENANCE

CORROSION PROTECTION

PROCEDURES

DRIVE SHAFT 366

DRIVE SHAFT BOOT 373

CARBON RING 373

03 – REVERSE SYSTEM 375

GENERAL 377

PROCEDURES 377

REVERSE CABLE 377

REVERSE CABLE LEVER 378

SHIFT LEVER 380

REVERSE CABLE SUPPORT 380

SHIFT LEVER HOUSING 381

REVERSE GATE 381

PIVOT SUPPORT 382

TABLE OF CONTENTS

LINK ROD

PIVOT TRIANGLE

PIVOT ARM 383

04 – VARIABLE TRIM SYSTEM (VTS) 385

GENERAL 387

TEST 387

VTS SWITCH

VTS MOTOR

VTS CONTROL MODULE 387

PROCEDURES 388

VTS UNIT 388

VTS RING

08 STEERING SYSTEM

01 – STEERING 393

GENERAL 396

ADJUSTMENT 396

STEERING ALIGNMENT 396

PROCEDURES 397

NOZZLE

HANDLEBAR GRIP

MULTIFUNCTION SWITCH

THROTTLE LEVER

THROTTLE CABLE 401

STEERING COVER 404

STEERING PADDING 406

HANDLEBAR EXTENSION 407

HANDLEBAR 407

STEERING CABLE SUPPORT 409

STEER ING SUPPORT 410

STEERING STEM 411

STEERING SUPPORT BEA RING

HANDLEBAR SUPPORT

STEERING CABLE

02 – OFF-POWER ASSISTED STEERING (0 P A S )

GENERAL

PROCEDURES

PLASTIC ELBOW

T-FITTING 421

WATER HOSE 422

SIDE VANE 422

CYLINDER 423

TIE ROD 426

SEALED TUBE 426

CROSS SUPPORT PLATE 427

09 BODY/HULL

VI

01 – BODY 429

GENERA L 450

PROCEDURES 450

DECALS

GLOVE BOX

SEAT 452

SEAT LATCH 454

ENGINE COVER 455

STORAGE COMPARTMENT COVER 456

TABLE OF CONTENTS

STORAGE COMPARTMENT COVER HINGE 457

STORAGE COMPARTMENT COVER SHOCK 457

STORAGE COMPARTMENT COVER INNER SHELL 458

FRONT GRILLE (STORAGE COMPARTMENT COVER) 461

BASKET LATCH 462

WIND DEFLECTOR

ACCESS COVER

CONSOLE

M IRROR

BUMPER

WAKE PYLON (MOULDED)

WAKE PYLON (ALUMINUM)

CARPET

02- HULL

GENERAL

PROCEDURES

INLET GRATE 477

RIDING PLATE 478

JET PUMP SUPPORT 479

TH RU-HULL FITIING 481

FRONT INNER CONTAINER 481

SPONSON 482

SPONSON ADAPTER 482

DRAIN PLUG 482

BOARDING STEP 483

BOW EYELET

STERN EYELETS

GELCOAT

10 TECHNICAL SPECIFICATIONS

01 – 1503 ENGINE 1130 HP) 489

02 – 1503 ENGINE (155 HP} 495

03 – 1503 ENGINE (215 HP) 501

04 – 1503 ENGINE 1255 HP) 507

11 ELECTRICAL CONNECTORS/WIRING DIAGRAM

01 – ELECTRICAL CONNECTORS 513

PROCEDURES 515

DEUTSCH CONNECTOR

PACKARD CONNECTOR

KOSTAL CONNECTOR (ECM)

BATIE RY AND STARTER CAB LE TERMINALS

02 – WIRING DIAGRAM

WIRE COLOR CODES

WIRE DIGIT CODES

PLEASE NOTE:

⦁ This is the SAME exact manual used by your dealers to fix your vehicle.

⦁ The same can be yours in the next 2-3 mins as you will be directed to the download page immediately after paying for the manual.

⦁ Any queries / doubts regarding your purchase, please feel free to contact [email protected]