New Holland Hydraulic Exavator E80MSR 604.13.421 Workshop Manual

FILE DETAILS:

New Holland Hydraulic Exavator E80MSR 604.13.421 Workshop Manual

Size : 53.6 MB

Format : PDF

Language : English

Number of Pages : 940 Pages

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

New Holland Hydraulic Exavator E80MSR 604.13.421 Workshop Manual

DESCRIPTION OF THE WORKSHOP MANUAL :

- This repair manual consists of one single volume, identified with: E80MSR – Workshop Manual “Hydraulic exavator”

- The “Hydraulic exavator” Workshop Manual contains the technical information necessary for machine service and repair, the service equipment, the information on maintenance standards, the removal and installing procedures, and the disassembly and assembly procedures.

- The complete Workshop Manual for the model E80MSR consists of the following volume identified by print number as shown herebelow: VOLUME MACHINE TYPE PRINT No. Workshop Manual – “Hydraulic exavator” E80MSR 604.13.421

This Manual is prepared as a technical material in which the information necessary for the maintenance and repairing services of our hydraulic excavators are collected, and is categorized into 7 Chapters, Specification, Maintenance, System, Disassembly, Troubleshooting, Engine, and Installation Procedures for Optional Attachment.

- The Chapter “Specification” describes the specifications for entire machine and material, which are instructive for replacement and repairing of attachments. • The Chapter “Maintenance” describes the material, which is helpful for maintenance service and adjustments for entire machine.

- The Chapter “System” describes the operating system like hydraulic system, electric system, components, and so on.

- The Chapter “Disassembly” describes the removal and installing of assembly mounted on the upper structure and undercarriage, and the assembling and disassembling of the associated hydraulic equipment.

- The Chapter “Troubleshooting” describes how to find the fault equipment.

- The Chapter “Engine” describes the engines making use of the “Maintenance Manual” provided by the suppliers. • The Chapter “Installation Procedures for Optional Attachment” describes the supplements added on request as required.

This Manual may be properly revised due to the improvement of products, modification of specifications, etc. And there are cases where the system on actual machine and a part of the contents of this manual may differ due to the variations of specification by countries. For the section in which the description is hardly understood, contact our distributor. The number is assigned to every part handled in this Manual on account of the description, but the parts, which cannot be supplied as service parts are contained. Therefore, the order must be placed with respective formal number with due confirmation on the Parts Manual for applicable machine.

INDEX DETAILS:

New Holland Hydraulic Exavator E80MSR 604.13.421 Workshop Manual

1. OUTLINE

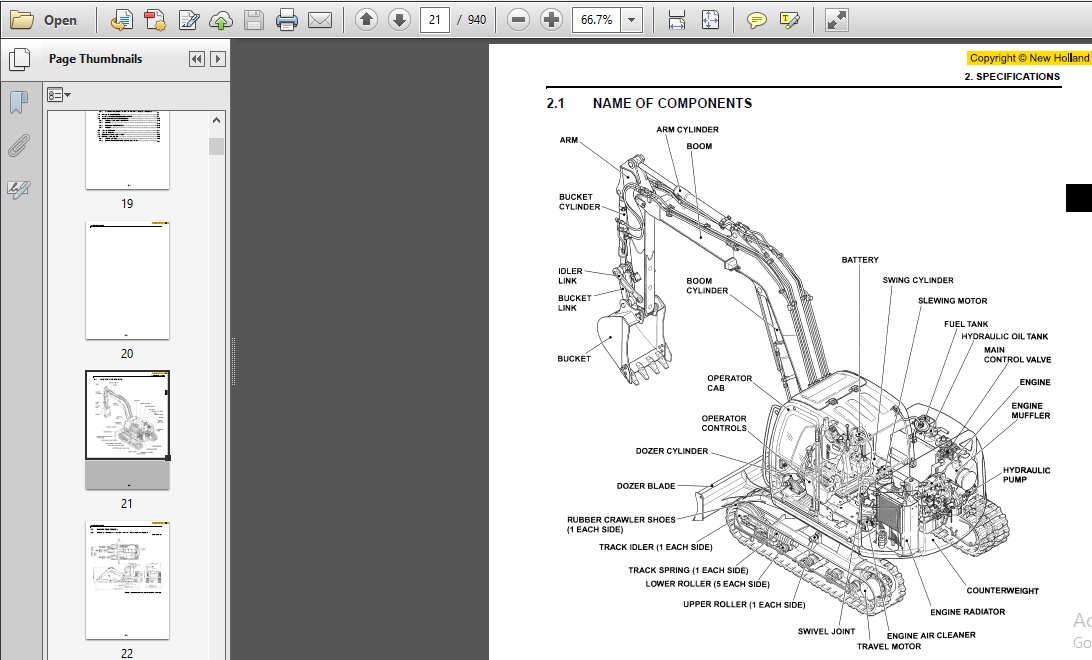

2. SPECIFICATIONS

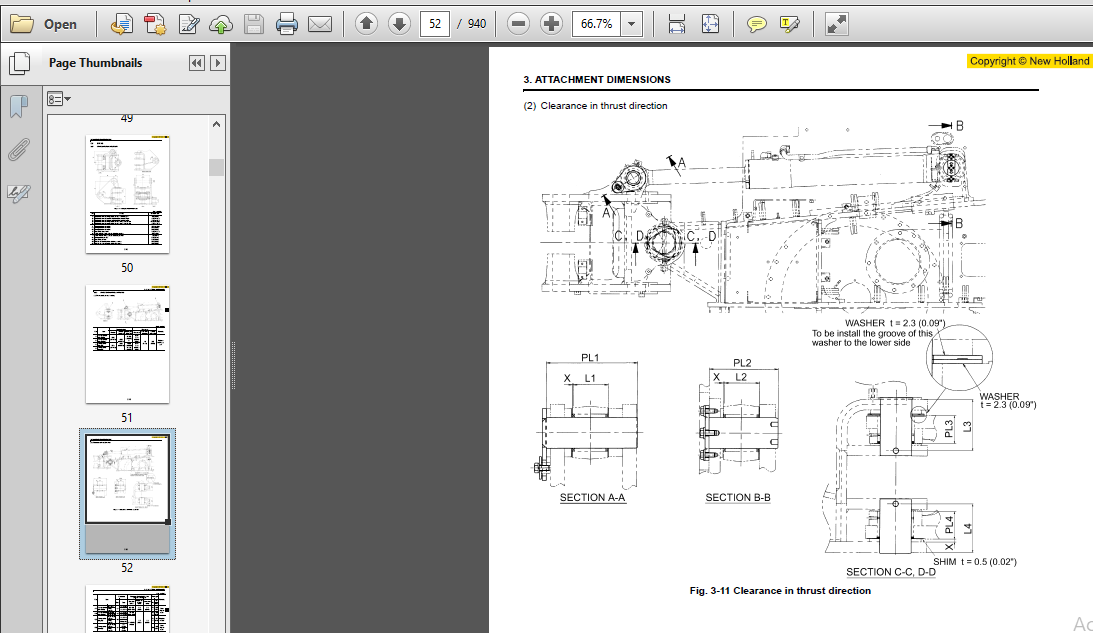

3. ATTACHMENT DIMENSIONS

11. TOOLS

12. STANDARD MAINTENANCE TIME SCHEDULE

13. MAINTENANCE STANDARD AND TEST

PROCEDURE

21. MECHATRO CONTROL SYSTEM

22. HYDRAULIC SYSTEM

23. ELECTRICAL SYSTEM

24. COMPONENTS SYSTEM

25. AIR-CONDITIONER SYSTEM

31. GENERAL DISASSEMBLY AND ASSEMBLY

32. ATTACHMENTS

33. UPPER SLEWING BODY

34. TRAVEL SYSTEM

41. TROUBLESHOOTING (MECHATRO CONTROL)

42. TROUBLESHOOTING (HYDRAULIC SYSTEM)

43. TROUBLESHOOTING (ELECTRIC)

44. TROUBLESHOOTING (ENGINE)

51. ENGINE

TABLE OF CONTENTS:

New Holland Hydraulic Exavator E80MSR 604.13.421 Workshop Manual

11 GENERAL PRECAUTIONS FOR REPAIRS 1-3

111 PREPARATION BEFORE DISASSEMBLING 1-3

112 SAFETY IN DISASSEMBLING AND ASSEMBLING 1-3

113 DISASSEMBLING AND ASSEMBLING HYDRAULIC EQUIPMENT 1-3

114 ELECTRICAL EQUIPMENT 1-4

115 HYDRAULIC PARTS 1-5

116 WELDING REPAIR 1-5

117 ENVIRONMENTAL MEASURE 1-5

12 INTERNATIONAL UNIT CONVERSION SYSTEM(Based on MARKS’ STANDARD

HANDBOOK FOR MECHANICAL ENGINEERS) 1-6

21 NAME OF COMPONENTS 2-3

22 MACHINE DIMENSIONS 2-4

221 372 m (12 ft-2 in) Boom + 18 m (5 ft-11 in) Arm + 028 m3 (037 cu•yd) Bucket 2-4

23 WEIGHT OF COMPONENTS 2-5

24 TRANSPORTATION DIMENSION AND WEIGHT 2-7

25 SPECIFICATIONS AND PERFORMANCE 2-10

251 SPEED AND CLIMBING CAPABILITY 2-10

252 ENGINE 2-10

253 HYDRAULIC COMPONENTS 2-10

254 WEIGHT 2-10

26 TYPE OF CRAWLER 2-11

27 TYPE OF BUCKET 2-11

28 COMBINATIONS OF ATTACHMENT 2-12

29 ENGINE SPECIFICATION 2-13

291 SPECIFICATIONS 2-13

292 ENGINE CHARACTERISTIC CURVE (ISUZU 4JG1) 2-14

31 BOOM 3-3

311 BOOM DIMENSIONAL DRAWING 3-3

312 BOOM MAINTENANCE STANDARD 3-4

32 ARM 3-6

321 ARM DIMENSIONAL DRAWING 3-6

322 ARM MAINTENANCE STANDARDS 3-9

33 BUCKET 3-12

331 BUCKET DIMENSIONAL DRAWING 3-12

332 BUCKET DIMENSIONAL TABLE 3-12

333 DETAIL DIMENSIONAL DRAWING OF LUG SECTION 3-13

334 DETAIL DIMENSIONAL DRAWING OF BOSS SECTION 3-14

34 DOZER 3-15

341 DOZER DIMENSIONAL DRAWING 3-15

342 DOZER MAINTENANCE STANDARD 3-16

35 SWING 3-18

351 SWING BRACKET DIMENSION 3-18

352 SWING MAINTENANCE STANDARD 3-19

111 TORQUE SPECIFICATIONS FOR CAPSCREWS & NUTS 11-3

1111 Metric Coarse Thread Standard Tightening Torque Values

Make Certainto tighten all Capscrews & Nuts to proper torque values 11-3

1112 Metric Fine Thread Standard Tightening Torque values

Make certainto tighten all Capscrews & Nuts to proper torque values 11-4

112 SCREW AND TOOL SIZES 11-5

1121 Capscrew 11-5

1122 Capscrew (Socket bolt) 11-5

1123 Setscrew 11-6

113 TORQUE SPECIFICATIONS FOR JOINTS AND HOSES 11-6

1131 JOINTS FOR PIPING (O-RING SEALING TYPE) 11-6

1132 HYDRAULIC HOSE (30 FLARE TYPE) 11-6

114 TORQUE SPECIFICATIONS FOR SLEEVE TYPE TUBE FITTINGS 11-7

1141 SLEEVE TYPE TUBE FITTINGS 11-7

1142 PART NO 11-7

115 PLUGS 11-8

1151 Plug for hydraulic pipe joint 11-8

1152 Plug for hydraulic equipment 11-9

116 SPECIAL SPANNERS FOR TUBES 11-10

117 SPECIAL TOOLS 11-11

118 APPLICATION OF SCREW LOCKING AND SEALING COMPOUNDS 11-12

119 SUCTION STOPPER 11-13

1110 COUNTERWEIGHT LIFTING JIG 11-14

1111 UPPER FRAME LIFTING JIG 11-15

1112 ENGINE MOUNTING PEDESTAL 11-16

1113 TRACK SPRING SET JIG 11-16

121 STANDARD MAINTENANCE TIME SCHEDULE FOR EXCAVATOR 12-4

122 STANDARD WORKING TIME TABLE FOR THE MAINTENANCE OF ENGINE 12-15

131 HOW TO USE MAINTENANCE STANDARD AND PRECAUTIONS 13-3

132 PERFORMANCE INSPECTION STANDARD TABLE 13-4

133 MEASUREMENT OF ENGINE SPEED 13-6

1331 MEASUREMENT OF ENGINE SPEED 13-6

134 MEASUREMENT OF HYDRAULIC PRESSURE 13-7

1341 PREPARING TO MEASURE HYDRAULIC PRESSURE 13-7

1342 PLACE TO INSTALL PRESSURE GAUGE 13-7

1343 PRESSURE ADJUSTMENT POSITION 13-8

1344 PROCEDURE FOR ADJUSTING RELIEF VALVE 13-10

135 MEASURING TRAVEL PERFORMANCES 13-11

1351 TRAVEL SPEED 13-11

1352 DEVIATION OF TRAVEL 13-11

1353 PERFORMANCES OF PARKING BRAKE 13-12

1354 DRAIN RATE OF TRAVEL MOTOR 13-13

136 MEASURING SLEWING PERFORMANCES 13-14

1361 SLEWING SPEED 13-14

1362 PERFORMANCE OF SLEWING BRAKE 13-14

1363 PERFORMANCE OF SLEWING PARKING BRAKE 13-15

1364 DRAIN RATE OF SLEWING MOTOR 13-16

137 MEASURING ATTACHMENT OPERATING PERFORMANCES 13-17

1371 OPERATING TIME OF CYLINDERS 13-17

1372 OIL TIGHTENESS OF CYLINDERS 13-18

138 MEASURING PERFORMANCES OF SLEWING BEARING 13-19

139 MECHATRO CONTROLLER “A” ADJUSTMENT 13-20

1391 ENGINE CONTROL INPUT / OUT 13-20

1392 ENGINE CONTROL INSTALLATION 13-20

1393 E/G CONTROL EQUIPMENT 13-21

1394 ADJUSTMENT OF MECHATRO CONTORL 13-22

211 SUMMARY OF MECHATRO CONTROL SYSTEM 21-4

212 BOOM RAISE CONFLUX MECHATRO CONTROL SYSTEM 21-7

213 SWING CUT VALVE CONTROL MECHATRO CONTROL SYSTEM 21-8

214 ARM IN / OUT CONFLUX MECHATRO CONTROL SYSTEM 21-9

215 TRAVEL STRAIGHT MECHATRO CONTROL SYSTEM 21-10

216 TRAVEL BOOST CONTROL SYSTEM 21-12

217 MECHATRO CONTROL 21-14

2171 TROUBLESHOOTING 21-14

2172 SERVICE DIAGNOSTICS 21-15

2173 COMPONENT MECHATRO CONTROL 21-17

221 SUMMARY 22-3

2211 FUNCTION AND FEATURES OF HYDRAULIC CIRCUIT 22-3

222 HYDRAULIC CIRCUITS AND COMPONENT MODELS 22-4

2221 STANDARD SPECIFICATION 22-5

2222 BOOM & ARM SAFETY SPECIFICATION 22-6

2223 EXTRA SPECIFICATION (OPT) 22-7

223 NEUTRAL CIRCUIT 22-8

224 TRAVEL CIRCUIT 22-10

225 BUCKET CIRCUIT 22-12

226 BOOM CIRCUIT 22-14

227 SLEWING CIRCUIT 22-18

228 ARM CIRCUIT 22-20

229 BOOM SWING CIRCUIT 22-24

2210 NIBBLER & BREAKER CIRCUIT 22-26

2211 COMBINED CIRCUIT (MULTIPLE CIRCUIT) 22-28

2212 DOZER CIRCUIT 22-32

2213 TRAVEL AND DOZER CIRCUIT 22-34

2214 CONTROL LINES 22-36

2215 UPPER & LOWER HYD LINES 22-48

2216 ATT HYD LINES 22-54

231 ELECTRICAL CIRCUIT DIAGRAM AND EQUIPMENT LIST 23-3

232 HARNESS 23-7

2321 HARNESS & CABLE LIST 23-7

2322 HARNESS CONNECTION DRAWING 23-8

2323 CONTROLLER ASSY 23-9

2324 INSTRUMENT PANEL ASSY 23-13

2325 UPPER ELECTRICAL ASSY 23-14

2326 UPPER HARNESS ASSY 23-16

2327 ENGINE HARNESS ASSY 23-22

2328 FLOOR PLATE HARNESS ASSY 23-24

2329 CAB HARNESS ASSY 23-26

23210 BATTERY 23-31

23211 CAB ASSY 23-32

23212 MOUNTING CAB 23-34

23213 MOUNTING LIGHT 23-34

23214 MOUNTING BOOM LIGHT 23-34

23215 MOUNTING CAB WORK LIGHT 23-35

23216 AIR CONDITIONER 23-37

23217 MOUNTING FUEL PUMP 23-38

23218 NAME PLATE INSTAL (ELECTRIC COMPONENT FOR AUTO IDLE STOP) 23-39

241 HYDRAULIC COMPONENTS 24-3

2411 HYDRAULIC PUMP & REGULATOR 24-3

2412 PILOT VALVE (ATT) 24-13

2413 PILOT VALVE (TRAVEL) 24-17

2414 CONTROL VALVE 24-22

2415 SWING MOTOR UNIT 24-57

2416 TRAVEL MOTOR 24-67

2417 SWIVEL JOINT 24-81

2418 CYLINDER 24-83

242 ELECTRIC EQUIPMENT 24-91

2421 ELECTRIC EQUIPMENT LIST FOR KCMA, KCME 24-91

2422 ELECTRIC EQUIPMENT LIST FOR ASIA, OCEANIA 24-94

2423 SPECIFICATION OF ELECTRIC EQUIPMENTS 24-97

251 CONSTRUCTION AND PIPING 25-3

2511 CONSTRUCTION 25-3

2512 PIPING 25-4

252 CONSTRUCTION OF MAIN COMPONENTS 25-6

2521 INTAKE UNIT 25-6

2522 AIR-CONDITIONER UNIT 25-7

2523 RECEIVER DRYER 25-8

253 FUNCTION 25-9

2531 MECHANISM OF COOLING CIRCUIT 25-9

2532 COOLING CIRCUIT 25-11

2533 COMPONENT PARTS 25-12

254 DISASSEMBLY AND ASSEMBLY 25-16

2541 PRECAUTIONS TO BE EXERCISED IN OPERATION 25-16

2542 REMOVAL AND INSTALLATION OF THE UNIT 25-17

255 CHARGING REFRIGERANT 25-21

2551 PRECAUTIONS TO BE EXERCISED IN OPERATION 25-21

2552 OPERATING PROCEDURE 25-22

2553 CHARGING PROCEDURE 25-23

256 ELECTRIC CIRCUIT 25-28

2561 WIRING DIAGRAM AND CONNECTORS 25-28

2562 INSPECTING FUNCTIONAL PARTS 25-30

257 TROUBLESHOOTING 25-32

311 GENERAL DISASSEMBLY AND ASSEMBLY 31-3

3111 CONTENTS OF GENERAL DISASSEMBLY AND ASSEMBLY 31-3

3112 SPECIFICATION OF TIGHTENING TORQUE 31-3

321 REMOVING AND INSTALLING 32-3

3211 ATTACHMENT AND COMPONENT 32-3

3212 BUCKET 32-4

3213 ARM 32-7

3214 BOOM 32-9

3215 SWING 32-14

3216 DOZER 32-16

322 DISASSEMBLING AND ASSEMBLING 32-17

3221 CYLINDER 32-17

331 REMOVING AND INSTALLING 33-3

3311 CAB 33-3

3312 OPERATOR SEAT 33-5

3313 BATTERY 33-6

3314 INSTRUMENT PANEL 33-7

3315 COUNTERWEIGHT 33-9

3316 GUARD 33-10

3317 UNDER COVER 33-14

3318 AIR CLEANER 33-15

3319 MUFFLER 33-17

33110 FUEL TANK 33-18

33111 HYDRAULIC TANK 33-20

33112 PUMP 33-23

33113 RADIATOR & OIL COOLER 33-27

33114 ENGINE 33-31

33115 MULTI CONTROL VALVE 33-35

33116 CONTROL VALVE 33-38

33117 PILOT VALVE (FOR ATT) 33-39

33118 PILOT VALVE (FOR TRAVEL) 33-40

33119 SWING UNIT 33-41

33120 SWIVEL JOINT 33-43

33121 UPPER FRAME 33-45

332 DISASSEMBLING AND ASSEMBLING 33-47

3321 HYDRAULIC PUMP • REGULATOR 33-47

3322 CONTROL VALVE 33-59

3323 PILOT VALVE (ATT) 33-73

3324 PILOT VALVE (TRAVEL) 33-83

3325 SWING MOTOR UNIT 33-89

3326 SWIVEL JOINT 33-103

341 REMOVING AND INSTALLING 34-3

3411 COMPONENTS OF TRAVEL SYSTEM 34-3

3412 CRAWLER 34-3

3413 UPPER ROLLER 34-7

3414 LOWER ROLLER (TRACK ROLLER) 34-12

3415 FRONT IDLER (IDLER ADJUSTER ASSY) 34-19

3416 SPROCKET 34-28

3417 TRAVEL MOTOR 34-30

3418 SLEWING BEARING 34-33

342 DISASSEMBLING AND ASSEMBLING 34-37

3421 TRAVEL MOTOR 34-37

411 OUTLINE 41-3

4111 JUDGMENT OF ACTUAL THING AT SITE 41-3

412 TABLE OF ACTUATOR FOR TROUBLESHOOTING : MECHATRO CONTROL 41-5

413 TROUBLESHOOTING SUMMARIZED : MECHATRO CONTROL 41-8

414 CHECK POINT FOR MECHATRO SYSTEM 41-10

421 TROUBLE DIAGNOSIS : HYDRAULIC 42-3

422 TROUBLESHOOTING 42-6

431 TROUBLE DIAGNOSIS TABLE : ELECTRIC 43-3

432 CONTROLLER ERROR CODE DISPLAY 43-7

433 SERVICE DIAGNOSIS 43-8

441 TROUBLE DIAGNOSIS : ENGINE 44-3

442 TROUBLESHOOTING 44-7

PLEASE NOTE:

- This is the SAME exact manual used by your dealers to fix your vehicle.

- The same can be yours in the next 2-3 mins as you will be directed to the download page immediately after paying for the manual.

- Any queries / doubts regarding your purchase, please feel free to contact [email protected]