Manitou MRT2150 M Series E-2 3B6 Series Instruments Operator’s Manual – PDF DOWNLOAD

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Manitou MRT2150 M Series E-2 3B6 Series Instruments Operator’s Manual – PDF DOWNLOAD

MRT2150

M SERIES E-2

3B6 SERIES INSTRUMENTS

S/N: 410185 THRU 411017

(INCLUDING S/N: 411020)

OPERATOR/SERVICE

MANUAL

SAFETY DECALS:

The purpose of this chapter is to introduce you to the safety messages, decals, and nameplates found on your forklift truck. The decals are identified by name, part number, location, and a brief description. (The forklift model logos, and other misc. decals not shown, can be found in your forklift parts manual.) The decals illustrated may not be exactly the same as those installed on your forklift; installation of the decals varies depending on the forklift model, series, decal updates, etc.. The size and location of some decals limit the amount of information that can be placed upon it.

- For this reason, additional detailed information not found on the decals is provided through-out this manual. Every decal placed on the lift truck is important; they are constant reminders of safety and instructions that should never be taken for granted.

- Even experienced operators can be seriously injured or killed by ignoring, refusing to enforce, or forgetting to follow safe operating procedures! Do not assume you know all safety issues concerning the decals. Before operating the lift truck; learn the meaning(s) of the decals as described in this manual.

- If any decal becomes illegible or missing, have it replaced immediately! Always replace decals using the same decal part no., unless otherwise specified by the manufacturer. For replacement decals not found in your parts manual, contact your nearest dealer. If you have any questions, contact your supervisor or nearest dealer for advice before operating your forklift!

ROUGH TERRAIN FORKLIFT TRUCK GENERAL SAFETY STANDARDS

STUDY THE OPERATOR/SERVICE MANUALS:

The information in this manual provides general instructions for the safe operation and maintenance of your forklift truck. This information is vital and must be clearly understood by the operator and serviceman. Study this manual and the Rough Terrain Forklift Safety Manual (part no. 422494) thoroughly and carefully before operating or servicing your forklift. Contact your dealer or Manitou North America, Inc. if you have any questions concerning your forklift, its operation, service or parts. Keep both manuals in the literature box on the forklift available for reference. If either manual becomes illegible or is missing, contact your dealer for replacements immediately. This manual cannot cover every situation that might result in an accident. It is the responsibility of the operator to always remain alert for potential hazards and be prepared to avoid them!

ADDITIONAL RECOMMENDED LITERATURE:

ANSI / ITSDF B56.6 is the national consensus standard for rough terrain forklift trucks. It contains rules about forklift safety, maintenance, safe operation, training, and supervision. Forklift owners should learn this standard and make it available for their operators, service personnel, and supervisors.

These standards can be obtained, free of charge, from the Industrial Truck Standards Development Foundation (ITSDF) on their website at www.itsdf.org. The following references are examples from the standard, addressing forklift operators:

A.) OPERATOR TRAINING QUALIFICATIONS

1.) The user shall ensure that operators understand that safe operation is the operator’s responsibility. The

user shall ensure that operators are knowledgeable of, and observe, all safety rules and practices.

2.) Create an effective operator training program centered around user company’s policies, operating conditions,

and rough terrain forklift trucks. The program should be presented completely to all new operators and

not be condensed for those claiming previous experience.

3.) Information on operator training is available from several sources, including rough terrain forklift truck manufacturers,

users, government agencies, etc.

4.) An operator training program should consist of the following:

a.) careful selection of the operator, considering physical qualifications, job attitude, and aptitude;

b.) emphasis on safety of stock, equipment, operator, and other personnel;

c.) citing of rules and why they were formulated;

d.) basic fundamentals of rough terrain forklift truck and component design as related to safety, e.g.,

in.-lb (N-m) loading, mechanical limitations, center of gravity, stability, etc.;

e.) introduction to equipment, control locations, and functions. Explain how they work when used

properly and problems when used improperly.

f.) supervise practice on operating course remote from normal activity and designed to simulate

actual operations, e.g., lumber stacking, elevating shingles to the roof, etc.;

g.) oral, written, and operational performance tests and evaluations during and at completion of the

course;

h.) refresher courses, which may be condensed versions of the primary

course, and periodic “on job” operator evaluation;

i.) understanding of nameplate data and operator instructions and warning information appearing on

the rough terrain forklift truck.

TABLE OF CONTENTS:

Manitou MRT2150 M Series E-2 3B6 Series Instruments Operator’s Manual – PDF DOWNLOAD

1 — INSTRUCTIONS

– Original replacement parts and

attachments.

– Driver’s operating instructions.

– Warning

– General instructions.

– Operating instructions.

– Handling instructions.

– Load handling.

– Maintenance instructions of the lift

truck.

– Before starting up a new lift truck.

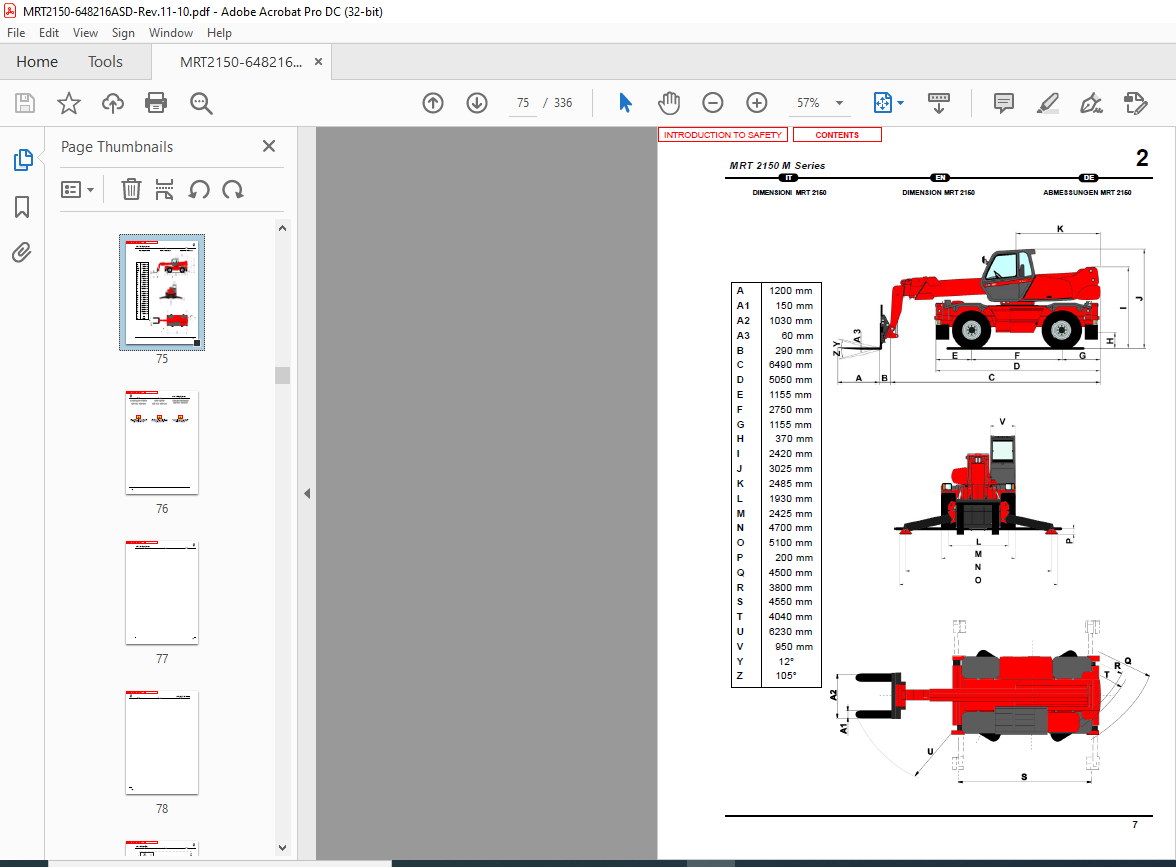

2 — DESCRIPTIION

– Characteristics.

– Dimensions and load charts.

– Instruments and controls.

3 — MAINTENANCE

– Filters cartridges and belts.

– Lubrificants.

– Servicing schedule.

A – Daily or every 10 hours service.

B – Every 50 hours service.

C – Every 250 hours service.

D – Every 500 hours service.

E – Every 1000 hours service.

F – Every 2000 hours service.

G – Every 5000 hours service.

H – Occasional maintenance.

4 — SYSTEMS

– Electrical system.

– Key to electrical system.

– Electrical system tables.

– Hydraulic system.

– Key to movement hydraulic system.

– Key to brake/steering hydraulic

system.

– Key to transmission hydraulic

system.

– Maintenance handbook

VIDEO PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the SAME exact manual used by your dealers to fix your vehicle.

- The same can be yours in the next 2-3 mins as you will be directed to the download page immediately after paying for the manual.

- Any queries / doubts regarding your purchase, please feel free to contact [email protected]

S.V