Liebherr Tractor PR 776 1296 Crawler dozer Service Manual – PDF DOWNLOAD

FILE DETAILS:

Liebherr Tractor PR 776 1296 Crawler dozer Service Manual – PDF DOWNLOAD

Language : English

Pages : 997

Downloadable : Yes

File Type : PDF

Size: 224 MB

DESCRIPTION:

Liebherr Tractor PR 776 1296 Crawler dozer Service Manual – PDF DOWNLOAD

This Service manual is intended for trained specialist staff in the Liebherr organization and its dealers.

The Service manual provides specific knowledge for the maintenance of Liebherr construction machinery. Basic technical knowledge of electrics, hydraulics, mechanics and Diesel engine technology are not detailed in this Service manual. A subject-based, qualified training is therefore necessary. Liebherr recommends participation on the Liebherr Training program for construction machinery.

In this Service manual you find information about:

For information relating to control and operation refer to the operator’s manual. For information relating to spare parts refer to the Spare parts catalog. Observe the locally applicable accident prevention regulations.

- Familiarize yourself with the operator’s manual before putting the machine into service. Also, ensure you have obtained, read, and understood any additional instructions regarding special accessories for the machine.

- Only authorized personnel may operate, maintain, or repair the machine. Remember to observe the minimum legal age limit.

- Utilize trained or instructed personnel and clearly define their responsibilities for operation, setup, maintenance, and repairs.

- Determine the machine operator’s responsibility, including adherence to traffic regulations, and empower them to refuse unsafe instructions from third parties.

- Do not allow untrained or trainee individuals to operate or work on the machine without constant supervision and guidance from an experienced instructor or operator.

- Periodically check and observe anyone operating or working on the machine to ensure they follow the safety instructions and guidelines provided in the operator’s manual.

- Always wear appropriate work clothing when operating or working on the machine. Avoid wearing rings, watches, ties, scarves, open jackets, or loose clothing that may pose a risk of injury by getting stuck or pulled in. Use prescribed safety equipment for specific tasks, such as safety glasses, safety shoes, safety helmets, work gloves, reflective vests, and ear protection.

- Consult the supervisor at the jobsite for special safety instructions and regulations.

- Maintain three-point contact when entering and exiting the machine.

- Never use joysticks as handholds when entering or exiting the machine to prevent inadvertent movement and serious accidents.

- Avoid jumping off the machine. Use designated steps, ladders, catwalks, and handles when climbing on or off the machine. Use both hands for support and face the machine.

- Keep steps, ladders, and handles free of oil, grease, mud, snow, and ice to minimize the risk of slipping, stumbling, or falling.

- Familiarize yourself with the emergency exit.

- If no other instructions are provided, follow this procedure for maintenance and repair work:

- Park the machine on solid and level ground.

- Bring all control levers to the neutral position.

- Set the parking switch to the park position.

- Turn off the engine and remove the ignition key.

- Actuate the control levers several times to relieve pressure in the servo lines.

- Bring all control levers to the neutral position.

- Before working on the hydraulic circuit, with the engine turned off and the ignition key in the contact position, move all pilot controls (joysticks and pedals) in both directions to relieve servo pressure and remaining back pressures in the working circuits. Then release the internal hydraulic tank pressure.

- Before leaving the operator’s seat, switch the parking switch to the park position.

- Secure all loose parts on the machine.

- Never operate the machine without conducting a complete walk-around inspection. Check if all warning signs are present on the machine and if they are legible.

- Observe all signs indicating danger and safety instructions.

IMAGES PREVIEW OF THE MANUAL:

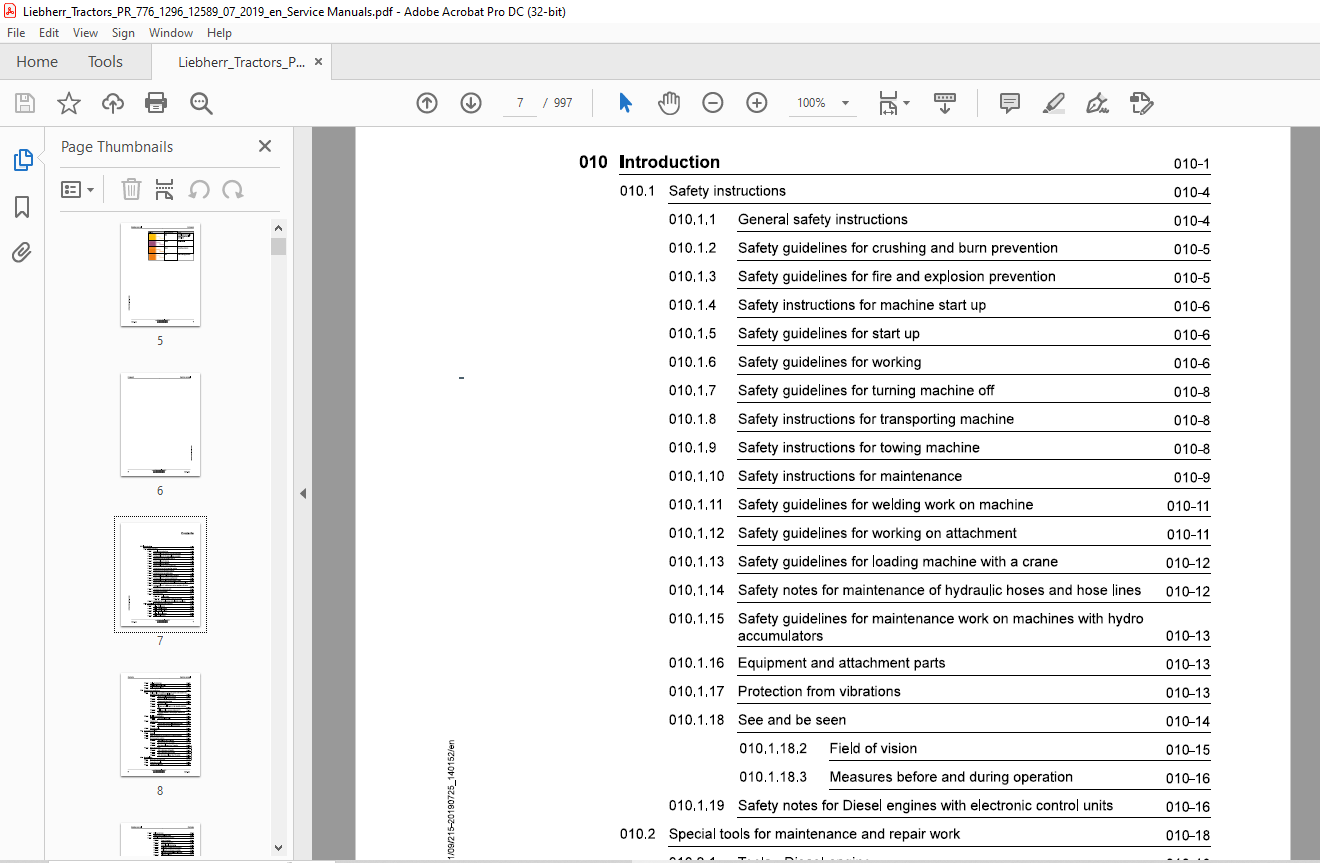

TABLE OF CONTENTS:

Liebherr Tractor PR 776 1296 Crawler dozer Service Manual – PDF DOWNLOAD

010.1 Safety instructions 010-4

0101.1 General safety instructions 010-4

010.1.2 Safety guidelines for crushing and burn prevention 010-5

010.1.3 Safety guidelines for fire and explosion prevention 010-5

010.14 Safety instructions for machine start up 010-6

0101.5 Safety guidelines for start up 010-6

010.1.6 Safety guidelines for working 010-6

0101.7 Safety guidelines for turning machine off 010-8

010.1.8 Safety instructions for transporting machine 010-8

010.1.9 Safety instructions for towing machine 010-8

010.1.10 Safety instructions for maintenance 010-9

010.1.11 Safety guidelines for welding work on machine 010-11

010.1.12 Safety guidelines for working on attachment 010-11

010.1.13 Safety guidelines for loading machine with a crane 010-12

010.1.14 Safety notes for maintenance of hydraulic hoses and hose lines 010-12

accumulators 010-13

010.1.16 Equipment and attachment parts 010-13

010.1.17 Protection from vibrations 010-13

010.1.18 See and be seen 010-14

010.1.18.2 Field of vision 010-15

010.1.18.3 Measures before and during operation 010-16

010.1.19 Safety notes for Diesel engines with electronic control units 010-16

010.2 Special tools for maintenance and repair work 010-18

010.2.1 Tools – Diesel engine 010-18

010.2.2 Tools – Hydraulic system 010-20

0102.3 Tools – Hydraulic cylinder 010-25

010.24 Tools – Electrical system 010-26

0102.5 Tools – Travel gearbox 010-28

010.2.7 Tools – Oscillating axle frame 010-31

010.2.8 Tools, operator’s platform 010-32

Standards and specifications 010-34

010.3.1 Preload values and tightening torques for screws with standard and

fine metric thread according to DIN ISO 261 010-34

010.3.1.1 Scope of application and purpose 010-34

010.3.1.2 Further applicable documentation 010-34

010.3.1.3 Changes and descriptions 010-35

010.3.1.4 Tightening values 010-35

010.3.1.5 Flanges and half flanges for high pressure (standard

62) 010-41

010.3.1.6 Half flange for low pressure (standard 61) 010-41

010.3.1.7 Tightening torques for cutting edges, end bits and

adapters 010-41

010.3.2 Installation specifications 010-42

010.3.2.1 Duo cone slipring seals 010-42

010.3.3 Tapping bores 010-44

010.3.3.1 Tapping bores of metric ISO standard threads 010-44

010.3.3.2 Tapping bores of metric ISO fine threads 010-46

010.3.4 Conversion tables 010-49

Conservation guidelines 010-50

0104.1 General 010-50

010.4.2 Taking the machine out of service for an unknown duration 010-50

010.4.3 Shut down of the machine 010-51

010.4.3.1 Shut down for up to 2 months 010-51

0104.3.2 Shut down for up to 12 months 010-52

010.4.33 Shut down for longer than 12 months 010-53

010.44 Return to operation 010-53

010.4.4.1 After a shut down of 2 months 010-53

010.4.4.2 After a shut down of 12 months 010-53

0104.43 After shut down of longer than 12 months 010-54

Repair welding 010-55

010.5.1 Preparation of cracked part 010-55

010.5.1 Preparation of a weld 010-56

010.5.1 Treatment of electrodes 010-56

010.5.1 Reinforcement of welding seam 010-57

010.5.1 General use of reinforcement sheeting 010-57

010.5.1.1 Form of sheeting 010-57

010.5.1.1 Thickness of sheeting 010-57

010.5.1.1 Material quality of sheeting 010-58

010.5.1.1 Application of reinforcement sheeting 010-58

010.5.1.1 Welding the reinforcement sheeting 010-58

010.5.1.1 Selection of correct welding electrodes 010-59

010.5.1.2 Electrode selection 010-59

010.5.1.2 Steel chart 010-60

010.5.1.2 Welding additives chart 010-61

010.6 Hydraulic symbols 010-65

010.7 Electrical symbols 010-75

010.8 Material weights 010-79

020 Technical data 020-1

020.1 Overall machine 020-3

020.1.1 Complete machine – Overview

PR776-1296/12589-; 020-3

020.2 Drive group 020-6

020.2.1 Diesel engine

PR776-1296/12589-; 020-6

020.2.2 Clutch

PR776-1296/12589-; 020-7

020.2.3 Splitter box

PR776-1296/12589-; 020-7

020.3 Cooling system 020-9

020.3.1 Regulator pump for coolant circuit

PR776-1296/12589-; 020-9

020.3.2 Fan drive gear motors of hydraulic oil cooler

PR776-1296/12589-; 020-9

020.3.3 Axial piston motor fan drive of water and charge air cooler

PR776-1296/12589-; 020-9

020.4 Working hydraulics 020-10

0204.1 Working hydraulics regulating pump

PR776-1296/12589-; 020-10

020.4.2 Front equipment, proportional control valve block

PR776-1296/12589-; 020-10

020.4.3 Lift cylinder

PR776-1296/12589-; 020-10

020.4.4 Tilt cylinder

PR776-1296/12589-; 020-11

020.5 Travel hydraulics 020-12

020.5.1 Variable displacement pump

PR776-1296/12589-; 020-12

020.5.2 Variable displacement motor

PR776-1296/12589-; 020-12

020.5.3 Double gear pump replenishing and pilot control working hydraulic

PR776-1296/12589-; 020-12

020.6 Hydraulic components 020-13

020.6.1 Hydraulic tank

PR776-1296/12589-; 020-13

020.7 Electrical system 020-14

020.7.1 Batteries – Installation

PR776-1296/12589-; 020-14

020.8 Travel gearbox 020-15

020.8.1 Travel gearbox

PR776-1296/12589-; 020-15

020.8.2 Brake system

PR776-1296; 020-16

020.9 Travel gear, axles, tyres, drive shafts 020-17

020.9.1 Travel gear frame

PR776-1296/12589-; 020-17

020.9.2 Idler

PR776-1296/12589-; 020-17

020.9.3 Tension unit

PR776-1296/12589-; 020-17

020.9.4 Track roller

PR776-1296/12589-; 020-17

020.9.5 Carrier roller (Optional)

PR776-1296/12589-; 020-17

020.9.6 Track chain

PR776-1296/12589-; 020-18

020.9.7 Sprocket

PR776-1296/12589-; 020-18

020.10 Working attachment 020-20

020.10.1 Semi U-blade

PR776-1296/12589-; 020-20

020.10.2 Cutting angle adjustment for blade

PR776-1296/12589-; 020-21

PR776-1296/12589-; 020-21

020.10.4 Rear equipment, proportional control valve block

PR776-1296/12589-; 020-22

020.10.5 Ripper with cutting angle adjustment

PR776-1296/12589-; 020-22

030 Maintenance 030-1

030.1 Maintenance and inspection schedule 030-8

030.2 Fill quantities, lubrication schedule 030-13

030.2.1 Recommended lubricants

PR776-1296/12589-; 030-13

030.22 Recommended fuel and operating fluids

PR776-1296/12589-; 030-14

0302.3 Lubrication schedule

PR776-1296; 030-14

030.3 Lubricants and fuels 030-17

030.3.1 General information about lubricants and fuels 030-17

030.3.1.1 General Information 030-17

030.3.1.2 General questions 030-17

030.3.1.3 Safety data sheets 030-17

030.3.1.4 Technical data sheets 030-17

030.3.1.5 Specific Liebherr standards 030-17

030.3.2 Diesel fuels

PR776-1296/12589-; 030-18

030.3.2.1 Specification 030-18

030.3.2.2 Sulfur content in Diesel fuel 030-18

030.3.2.3 Diesel fuel – Lubricity 030-18

030.3.2.4 Ignitability 030-18

030.3.2.5 Diesel fuels at low temperatures (winter operation) 030-18

030.3.3 Lubricating oils for Diesel engines

PR776-1296/12589-; 030-19

030.3.3.1 Lube oil quality 030-19

030.3.3.2 Lube oil viscosity 030-19

030.3.3.3 Lube oil change intervals 030-20

030.34 Coolant for Diesel engines

PR776-1296/12589-; 030-20

030.3.4.1 General recommendations 030-20

030.34.2 Water (Fresh water) 030-21

030.3.4.3 Coolant mixing ratio 030-21

030.3.4.4 Approved anti-freeze and corrosion protection agent 030-22

030.3.4.5 Approved premixed anti-freeze and corrosion protec-

tion agent 030-22

030.3.4.6 Approved corrosion inhibitors without antifreeze

protection 030-23

030.3.5 Hydraulic oil

PR776-1296; 030-23

030.3.5.1 Liebherr Hydraulic oil 030-23

030.3.5.2 Engine oil as hydraulic oil 030-24

030.3.5.3 Warm up specification 030-25

030.3.5.4 Biodegradable hydraulic oils 030-25

030.3.5.5 Oil change, oil analysis, filter change 030-26

030.3.6 Lube oils for splitterboxes

PR776-1296; 030-28

030.3.6.1 Quality 030-28

030.3.6.2 Viscosity 030-29

030.3.7 Lube oils for travel gearbox

PR776-1296/12589-; 030-29

030.3.7.1 Quality 030-29

030.3.7.2 Viscosity 030-30

030.3.7.3 Oil change 030-30

030.3.8 Qil for duo cone (slipring) seal Travel gear

PR776-1296; 030-31

030.3.9 Grease and other lubricants

PR776-1296/12589-; 030-31

030.3.10 Qil for hinges and joints

PR776-1296; 030-32

030.3.11 Qi for axle bearing

PR776-1296; 030-33

030.4 Maintenance tasks 030-34

030.4.1 Safety instructions for maintenance

PR776-1296; 030-34

030.4.2 Maintenance – preparations 030-34

0304.21 Maintenance position

PR776-1296/12589-; 030-34

030.4.2.2 Turn the electrical system off

PR776-1296; 030-37

030.4.2.3 Lift the operator’s cab

PR776-1296/12589-; 030-37

Overall machine 030-42

030.4.3.1 Checking the machine for external damage, correct

030.4.3.2 Lubricating all lube points according to lubrication

030.4.3.3 Checking the window wiper

030.4.3.4 Check the hose clamp with spring pretension

030.4.3.5 Oil samples and oil analysis

030.4.3.6 Wet cleaning the machine

030.4.3.7 Protect the piston rods

030.4.3.8 Taking the machine out of service

Drive group 030-51

030.4.4.1 Checking the engine oil level

030.4.4.2 Changing the engine oil

030.4.4.3 Changing lube oil filters

030.4.4.4 Checking the diesel engine configuration and the

030.4.4.5 Checking and changing ribbed V-belt

030.44.6 Check the Diesel engine arrangement for leaks and

030.4.4.7 Check the intake and exhaust lines for mounting and

030.4.4.8 Check the electrical system of the Diesel engine

030.4.4.9 Changing oil separator filter cartridge

030.4.4.10 Checking and changing heater flange

030.4.4.13 Fuel preliminary filter: Drain the condensation

PR776-1296/12589-; 030-61

030.4.4.14 Fuel tank: Drain condensation and sediments

PR776-1296/12589-; 030-62

0304.4.15 Changing fuel pre-filter cartridge

PR776-1296/12589-; 030-63

030.4.4.16 Changing fuel fine filter

PR776-1296/12589-; 030-65

030.4.4.17 Empty and clean the fuel tank

PR776-1296/12589-; 030-66

030.4.4.18 Venting fuel system

PR776-1296/12589-; 030-68

030.4.4.20 Replacing the air filter

PR776-1296/12589-; 030-70

030.4.4.21 Splitterbox: Check the oil level

PR776-1296/12589-; 030-73

030.4.4.22 Splitterbox: Change the oil

PR776-1296/12589-; 030-74

030.4.5 Cooling system 030-76

030.4.5.1 Check the coolant level and refill

PR776-1296/12589-; 030-76

0304.5.2 Check the cooling system for contamination and

clean it

PR776-1296/12589-; 030-78

0304.53 Checking the cooling system

PR776-1296/12589-; 030-80

030.4.5.4 Check the antifreeze concentration in the coolant.

PR776-1296; 030-83

030.4.5.5 Changing the coolant

PR776-1296/12589-; 030-90

030.4.6 Travel hydraulics 030-91

030.4.6.1 Change the replenishing circuit filter

PR776-1296/12589-; 030-91

030.4.7 Hydraulic components 030-95

030.4.7.1 Checking the oil level in the hydraulic tank and

topping up oil

PR776-1296/12589-; 030-95

030.4.7.2 Clean the magnetic rod on the hydraulic tank

PR776-1296/12589-; 030-98

030.4.7.3 Checking the hydraulic system for function and leaks

PR776-1296/12589-; 030-99

030.4.7.4 Clean the oil cooler

PR776-1296/12589-; 030-100

PR776-1296/12589-; 030-101

030.4.7.6 Drain water and sediments in the hydraulic tank

PR776-1296/12589-; 030-104

030.4.7.7 Change the return filter insert

PR776-1296/12589-; 030-105

0304.8 Electrical system 030-107

030.4.8.1 Check the display unit and lighting

PR776-1296/12589-; 030-107

030.4.8.2 Check the batteries

PR776-1296/12589-; 030-107

030.4.8.3 Change the light bulbs

PR776-1296/12589-; 030-111

030.4.9 Travel gearbox 030-111

030.4.9.1 Travel gearbox: checking the condition

PR776-1296; 030-111

030.4.9.2 Check the oil level

PR776-1296/12589-; 030-111

030.4.9.3 Changing the oil

PR776-1296/12589-; 030-112

030.4.9.4 Check the oil level in the duo cone (slipring) area

PR776-1296/12589-; 030-115

030.4.9.5 Change oil in brake chamber

PR776-1296/12589-; 030-116

030.4.9.6 Change the oil in the duo cone (slip ring) area

PR776-1296/12589-; 030-117

0304.10 Travel gear, axles, tyres, drive shafts 030-122

030.4.10.1 Checking the nuts and bolts of the travel gear

components are firmly seated

PR776-1296/12589-; 030-122

030.4.10.2 Check the seal on the carrier rollers, track rollers,

idlers and track carriers for leaks

PR776-1296/12589-; 030-123

030.4.10.3 Checking and adjusting the track tension

PR776-1296/12589-; 030-124

030.4.104 Change the track

PR776-1296/12589-; 030-128

030.4.10.5 Checking travel gear guides

PR776-1296/12589-; 030-131

030.4.10.6 Checking the oil fill of the axle bearings

PR776-1296/12589-; 030-134

030.4.10.7 Greasing equaliser bar bearing

PR776-1296/12589-; 030-135

030.4.10.8 Check the rubber stop of the equalizer bar

PR776-1296/12589-; 030-136

030.4.10.9 Check the oil level of the track carriers

PR776-1296/12589-; 030-136

030.4.10.10 Checking the chain guides for wear

PR776-1296/12589-; 030-138

030.4.10.11 Checking idler spacing and adjusting it, if necessary

PR776-1296/12589-; 030-139

030.4.11 Working attachment 030-141

030.4.11.1 Checking the cutting edges, corners and ripper teeth

for wear

PR776-1296/12589-; 030-141

0304.11.2 Lubricate the working attachment and hoist cylinder

bearing

PR776-1296/12589-; 030-142

0304.11.3 Check the working equipment

PR776-1296/12589-; 030-142

0304.11.4 Checking bearing points of working attachment for

play and wear

PR776-1296/12589-; 030-143

030.4.11.5 Checking the mounting screws and pin retainers of

the working attachment for tight seating

PR776-1296; 030-146

030.4.11.6 Removing and installing the ripper tooth tips

PR776-1296/12589-; 030-147

030.4.12 Operator’s cab, heating, air conditioning 030-150

030.4.12.1 Checking the heating for function and leaks

PR776-1296/12589-; 030-150

0304.12.2 Clean and replace the heater fresh air filter and air

circulation filter

PR776-1296/12589-; 030-151

030.4.12.3 Inspection of the air conditioning system by HVAC

specialist staff

PR776-1296/12589-; 030-153

030.4.124 Check the compressor mounting

PR776-1296/12589-; 030-154

030.4.12.5 To check the capacitor

PR776-1296/12589-; 030-154

030.5 Testing and adjustment checklist

PR776-1296/12589-; 030-155

030.5.1 Adjustment checklist 030-155

030.5.2 Track Components Check List 030-167

030.5.2.1 Test report 030-167

030.5.2.2 Wear data 030-171

030.5.2.3 Track inner wear measurement (Intertrac) 030-174

030.6 Check and adjustment tasks 030-176

PR776-1296; 030-176

0306.2 Overall machine 030-177

030.6.2.1 Preparations for check and adjustment tasks

PR776-1296/12589-; 030-177

030.6.2.2 Visual inspection and maintenance

PR776-1296/12589-; 030-179

030.6.2.3 Bringing the machine to operating temperature

PR776-1296/12589-; 030-180

030.6.2.3 Various procedures can be selected for reaching the

operating temperature:

PR776-1296/12589-; 030-180

0306.3 Drive group 030-181

030.6.3.1 Engine speed controller of diesel engine — deter-

mining adjustment range

PR776-1296/12589-; 030-181

0306.4 Cooling system 030-184

030.6.4.1 Checking the stand-by pressure for the fan control

PR776-1296/12589-; 030-184

030.6.4.2 Checking the pressure relief valve – fan motor and

fan control

PR776-1296/12589-; 030-187

0306.5 Working hydraulics 030-193

030.6.5.1 Checking the standby pressure

PR776-1296/12589-; 030-193

030.6.5.2 Checking the primary pressure relief valve on the

control valve block

PR776-1296/12589-; 030-194

030.6.5.3 Checking the secondary pressure relief valve on the

control valve block

PR776-1296/12589-; 030-195

030.6.5.4 Checking pressure cut-off valves

PR776-1296/12589-; 030-197

030.6.5.5 Checking the pressure difference HD-LS

PR776-1296/12589-; 030-199

030.6.5.6 Checking the nitrogen fill in the hydro accumulator

PR776-1296/12589-; 030-200

0306.6 Travel hydraulics 030-200

030.6.6.1 Checking the supply pressure of the variable pump

PR776-1296/12589-; 030-200

030.6.6.2 Checking and adjusting the pressure limitation for

high pressure

PR776-1296/12589-; 030-201

0306.7 Electrical system 030-204

PR776-1296/12589-; 030-204

0306.7.2 Checking travel joystick

PR776-1296/12589-; 030-215

0306.7.3 Calibrating inching brake pedal

PR776-1296/12589-; 030-228

030.6.7.4 Brake test

PR776-1296/12589-; 030-235

030.6.7.5 Overspeed safety test (option)

PR776-1296/12589-; 030-239

030.6.7.6 Parameter adjustment options

PR776-1296/12589-; 030-241

030.6.7.7 Addressing CAN modules

PR776-1296; 030-243

040 Drive group 040-1

040.1 Diesel engine 040-2

040.1.1 Diesel engine — full overview

PR776-1296/12589-; 040-2

040.1.2 Fuel system 040-6

040.1.2.1 Fuel system

PR776-1296/12589-; 040-7

040.1.2.2 Fuel quantity sensor

PR776-1296/12589-; 040-8

040.1.2.3 Fuel pre-filter and fuel fine filter

PR776-1296/12589-; 040-9

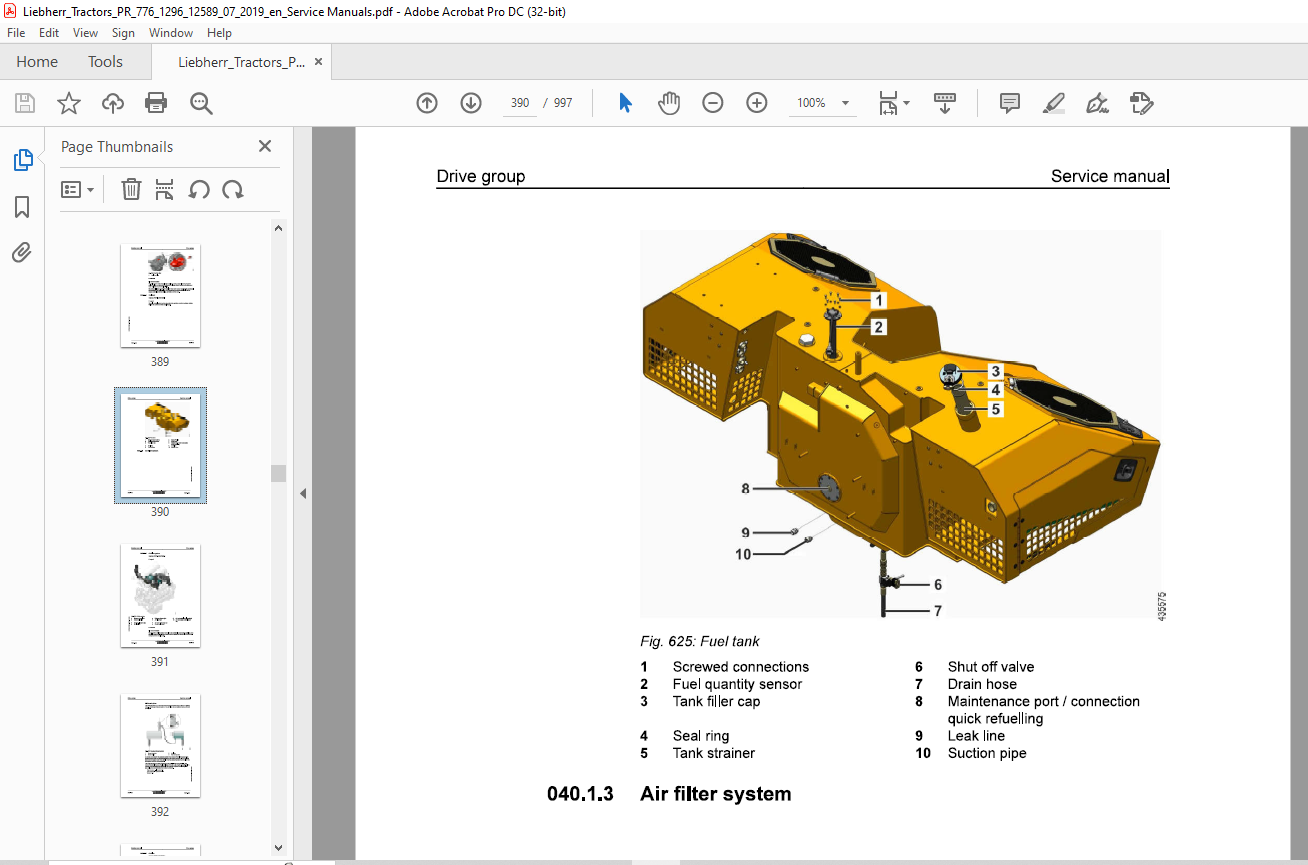

040.1.2.4 Fuel tank

PR776-1296/12589-; 040-13

040.1.3 Air filter system 040-14

040.1.3.1 Air filter system

PR776-1296/12589-; 040-15

040.1.3.2 Air filter

PR776-1296/12589-; 040-17

040.1.4 Exhaust system 040-18

040.1.4.1 Exhaust system – full overview

PR776-1296/12589-; 040-18

040.1.5 Diesel engine mounting

PR776-1296/12589-; 040-19

040.2 Clutch

PR776-1296/12589-; 040-20

040.3 Splitter box

PR776-1296/12589-; 040-22

050.1 Complete cooling system

PR776-1296/12589-; 050-2

050.2 Cooler arrangement 050-5

0502.1 Combi cooler

PR776-1296/12589-; 050-6

050.3 Hydraulic 050-14

050.3.1 Gear motor – fan oil cooler

PR776-1296/12589-; 050-14

050.3.2 Axial piston fixed displ. motor – fan drive

PR776-1296/12589-; 050-15

060 Working hydraulics 060-1

060.1 Working hydraulics – Full overview

PR776-1296/12589-; 060-2

060.2 Regulating pump 060-14

0602.1 Regulating pump – full overview

PR776-1296/12589-; 060-14

060.3 Proportional control valve block 060-19

060.3.1 Proportional control valve block – working attachment front – full

overview

PR776-1296/12589-; 060-20

060.4 Pilot control Working hydraulic 060-23

060.4.1 Pilot control Full overview

PR776-1296/12589-; 060-23

060.5 Hydraulic cylinder 060-29

060.5.1 Lift cylinder

PR776-1296/12589-; 060-29

0605.2 Tilt cylinder

PR776-1296/12589-; 060-30

070 Travel hydraulics 070-1

070.1 Complete travel hydraulics

PR776-1296/12589-; 070-2

070.2 Regulating pump

PR776-1296/12589-; 070-14

070.3 Variable displacement pump

PR776-1296/12589-; 070-18

070.4 Variable displacement motors 070-27

0704.1 Variable displacement motors – Full overview

PR776-1296/12589-; 070-27

070.5 Distributor block 070-36

070.5.1 Distributor blocks

PR776-1296/12589-; 070-36

080 Hydraulic components 080-1

080.1 Hydraulic cylinder 080-2

080.1.1 Ripper cylinder

PR776-1296/12589-; 080-2

080.1.2 Valves

PR776-1296/12589-; 080-3

080.2 Hydraulic tank 080-16

080.2.1 Hydraulic tank

PR776-1296/12589-; 080-16

080.2.2 Return filter

PR776-1296/12589-; 080-20

100 Brake system 100-1

100.1 Inching brake pedal 100-2

100.1.1 Speed reduction pedal

PR776-1296/12589-; 100-2

110 Electrical system 110-1

110.1 Electrical system – Full overview

PR776-1296; 110-4

110.2 Lighting system

PR776-1296/12589-; 110-7

110.3 Circuit diagrams

PR776-1296/12589-; 110-10

110.4 Electrical components in operator’s cab

PR776-1296; 110-11

110.4.2 Central control – Master (A100)

PR776-1296/12589-; 110-18

110.4.3 Travel sensor

PR776-1296/12589-; 110-24

110.44 Speed control

PR776-1296/12589-; 110-26

110.5 Electrical components – Heatable exterior mirror (option)

PR776-1296/12589-; 110-28

110.6 Electrical components – Diesel engine

PR776-1296/12589-; 110-29

110.7 Electrical components – Main frame

PR776-1296/12589-; 110-38

110.8 Electrical components Compartments 110-43

110.8.2 Fuel tank

PR776-1296/12589-; 110-44

110.8.3 Central electrical system compartment

PR776-1296/12589-; 110-45

110.8.4 Hydraulic tank

PR776-1296/12589-; 110-51

110.9 Display unit

PR776-1296/12589-; 110-52

110.10 Electrical components LiDAT (option)

PR776-1296/12589-17835; 110-53

110.11 Electrical components LiDAT (option)

PR776-1296/17836-; 110-54

110.12 Electrical components LiTU2 (option)

PR776-1296/12589-; 110-55

110.13 Electrical components LiTU3 (option)

PR776-1296/12589-; 110-56

110.14 Electrical components – Incline alarm (option)

PR776-1296/12589-; 110-57

110.15 Electrical components – Data interface (option)

PR776-1296/12589-; 110-60

110.16 Electrical components – Input module A240 (option)

PR776-1296/12589-; 110-63

110.17 Electrical components – Output module A135 (option)

PR776-1296/12589-; 110-65

110.18 Electrical components – Travel hydraulics pressure cut-off

PR776-1296/12589-; 110-67

110.19 Electrical components – Acoustic reversing warning device (option)

PR776-1296/12589-; 110-68

110.20 Electrical components – Disengageable reversing warning device (option)

PR776-1296/12589-; 110-70

110.21 Electrical components – Optical reversing waming device (option)

PR776-1296/12589-; 110-73

110.22 Electrical components – Engine after-run

PR776-1296/12589-; 110-76

110.23 Electrical components – Access ladder

PR776-1296/12589-; 110-77

110.24 Electrical components – Warm water heating device (option)

PR776-1296/12589-; 110-80

110.25 Electrical components – Jump-start (option)

PR776-1296/12589-; 110-85

110.26 Electrical components – Reversible fan drive (option)

PR776-1296/12589-; 110-86

110.27 Electrical components – Working hydraulics cutting angle adjustment (option)

PR776-1296/12589-; 110-88

110.28 Electrical components – 3-point belt with warning sound (option)

PR776-1296/12589-; 110-91

110.29 Electrical components – Supply box for external users (option)

PR776-1296/12589-; 110-94

110.30 Electrical components – Coolant level check (option)

PR776-1296/12589-; 110-97

110.31 Electrical components – External operating hour meter (option)

PR776-1296/12569-; 110-99

110.32 Electrical components – Generator disconnecting switch (option)

PR776-1296/12589-; 110-100

110.33 Electrical components – Ripper headlight (option)

PR776-1296/12589-; 110-102

110.34 Electrical system – Cooling water preheating (option)

PR776-1296/12589-; 110-105

120 Travel gearbox 120-1

120.1 Travel gear, overall

PR776-1296/12589-; 120-2

120.2 Brake system

PR776-1296/12589-; 120-7

120.3 Duo cone slipring seal

PR776-1296/12589-; 120-9

120.4 External oil supply

PR776-1296/12589-; 120-10

130 Travel gear, axles, tyres, drive shafts 130-1

130.1 Travel gear frame 130-2

130.1.1 Support frame

PR776-1296/12589-; 130-2

130.2 Idler

PR776-1296/12589-; 130-3

130.3 Tension unit

PR776-1296/12589-17311; 130-4

130.4 Tension unit

PR776-1296/17312-; 130-5

130.5 Track roller

PR776-1296/12589-; 130-6

130.6 Carrier roller (Optional)

PR776-1296/12589-; 130-7

130.7 Function, wear and evaluation

PR776-1296; 130-8

PR776-1296/12589-; 160-13

140.1 Lift cylinder suspension

PR776-1296/12589-; 140-2

140.2 Oscillating axle frame

PR776-1296/12589-; 140-3

140.3 Push frame

PR776-1296/12589-; 140-5

150 Working attachment 150-1

150.1 Semi U-blade

PR776-1296/12589-; 150-2

150.2 Hydraulic cutting angle adjustment

PR776-1296/12589-; 150-4

150.3 Ripper

PR776-1296; 150-14

150.3.1 Ripper proportional control valve block – Full overview

PR776-1296/12589-; 150-14

150.4 Cutting angle adjustment – Ripper

PR776-1296/12589-; 150-17

160 Operator’s cab, heating, air conditioning 160-1

160.1 Operator’s platform 160-2

160.1.1 Operator’s platform installations

PR776-1296/12589-; 160-2

160.1.2 Operator’s platform bearing

PR776-1296/12589-; 160-3

160.1.3 Support cylinder

PR776-1296/12589-; 160-6

160.2 Operator’s cab 160-10

160.2.1 Operator’s seat

PR776-1296/12589-; 160-10

160.3 Heater and ventilation 160-11

8 160.3.1 Warm water heater 160-11

a 160.3.1.1 Hose routing for warm water heating device

5 PR776-1296/12589-; 160-11

3 160.4 Heating, ventilation, air conditioning 160-13

160.4.1 Heating and air conditioning system 160-13

190 Options 190-1

PR776-1296/12589-; 190-2

200 Service codes, Diagnostics 200-1

200.2 Testing and adjustment software 200-2

200.21 Wizard test and adjustment software 200-2

200.2.1.1 General 200-2

200.2.1.2 Symbols 200-3

200.2.1.3 Information window 200-73

VIDEO PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is not a physical manual but a digital manual – meaning no physical copy will be couriered to you. The manual can be yours in the next 2 mins as once you make the payment, you will be directed to the download page IMMEDIATELY.

- This is the same manual used by the dealers inorder to diagnose your vehicle of its faults.

- Require some other service manual or have any queries: please WRITE to us at [email protected]

S.V