Liebherr L 566 1616 Wheel Loader Operator’s Manual SN 37904 – PDF DOWNLOAD

FILE DETAILS:

Liebherr L 566 1616 Wheel Loader Operator’s Manual SN 37904 – PDF DOWNLOAD

Language : English

Pages : 276

Downloadable : Yes

File Type : PDF

Size: 59.6 MB

DESCRIPTION:

Liebherr L 566 1616 Wheel Loader Operator’s Manual SN 37904 – PDF DOWNLOAD

Product ID

Manufacturer: Liebherr Machinery (Dalian) Co.Ltd.

Type: L 566

Type no.: 1616

From Serial no.: 37904

Preface:

This operating manual has been written for the driver and for the maintenance personnel of the machine.

It contains the following descriptions:

- Chapter 1: Product description

- Chapter 2: Safety regulations

- Chapter 3: Handling and operation

- Chapter 4: Malfunctions

- Chapter 5: Maintenance

This operating manual must be carefully read before initial operation and should be read and used later at regular intervals by anyone who carries out work on the machine.

Working with or on the machine includes:

- Operation, including equipping, troubleshooting during operation, removing production debris, maintenance, removing operating and auxiliary materials.

- Servicing, including maintenance, inspection, and repairs.

- Transport or loading the machine.

This manual helps the driver to become acquainted with the machine and prevents malfunctions due to incorrect operation.

Observation of the operating manual by maintenance staff:

- Increases reliability during operation.

- Extends the service life of your machine.

- Reduces repair costs and downtime.

This manual must be kept with the machine. Make sure a copy is always kept in the glove compartment of the driver’s cab.

In addition to the operating manual, follow the instructions based on existing national accident prevention and environmental protection regulations.

In addition to the operating manual and applicable national and local legal accident prevention rules, observe the recognized technical regulations for safe and correct operation.

This operating manual contains all the information you need to operate and service your machine.

- Some illustrations in this manual may show details and equipment that are different from those on your machine.

- On some pictures, protective devices and covers have been removed for a better view.

- We constantly make improvements to our machines, which means there may have been modifications to your machine which are not mentioned in this manual.

However, if you should require explanations or information, the Liebherr technical information and customer services departments will be happy to provide assistance.

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Liebherr L 566 1616 Wheel Loader Operator’s Manual SN 37904 – PDF DOWNLOAD

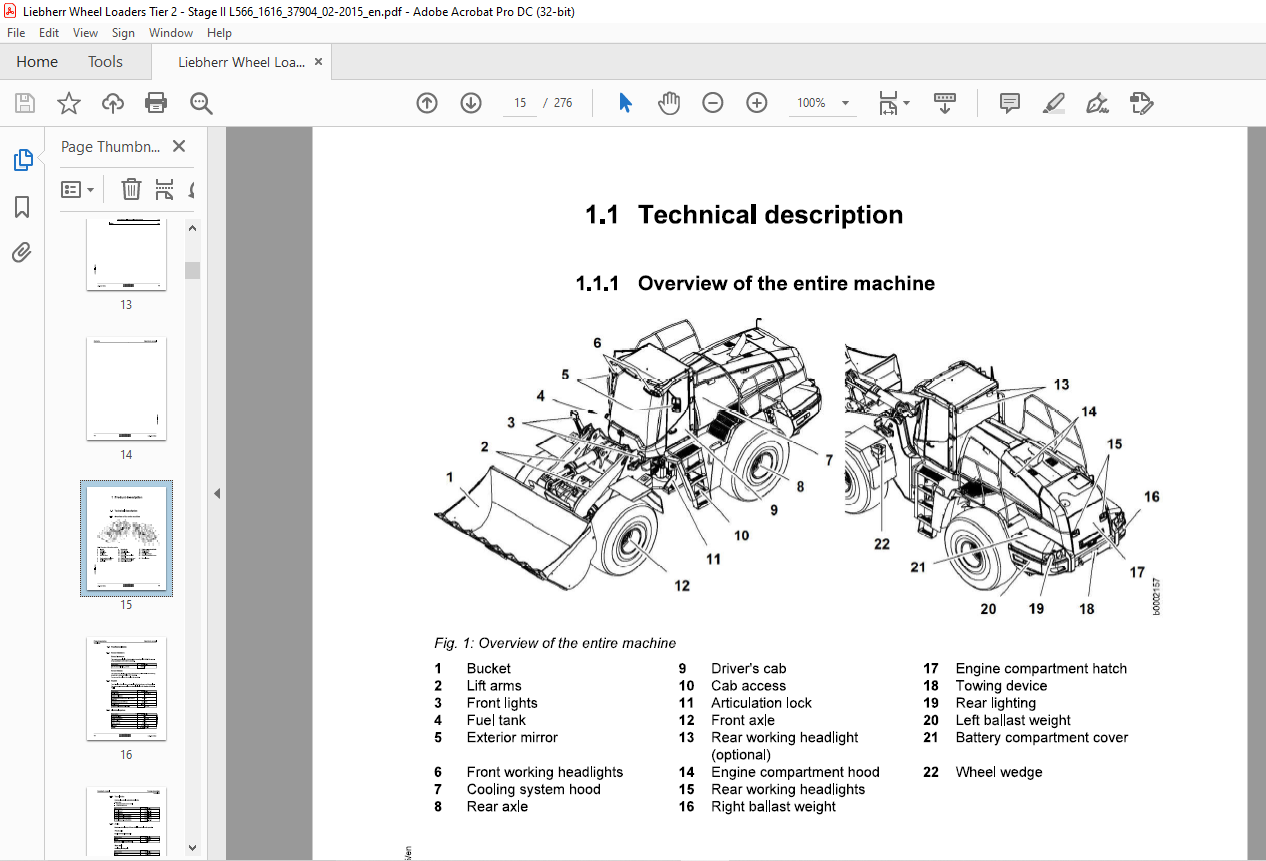

1.1 Technical description 16

1.1.1 Overview of the entire machine 15

1.2 Technical data 16

1.2.1 Sound emission 16

1.2.2 Engine 16

1.2.3 Electrical system 16

1.2.4 Travel drive 17

1.2.5 Axles 17

1.2.6 Braking 17

1.2.7 Steering 18

1.2.8 Working hydraulics 18

1.29 Liftarms 18

1.2.10 Driver’s cab 19

1.2.11 Heating, ventilation, air conditioning 19

1.2.12 Towing device 19

1.2.13 Ballast 20

1.2.14 Tyres 21

1.2.15 Snow chains or guard chains 22

1.2.16 Tyres with foam 23

1.2.17 Complete machine with loading bucket 23

1.2.18 Complete machine with bucket (industrial lift arms) 25

1.2.19 Attachment: Light material bucket 27

1.2.20 Attachment: Timber grabber 28

2 Safety warnings, signs 31

21 How the warnings are marked 31

2.1.1 Further markings 31

21.2 Additional rules and guidelines 32

2.2 Proper use 32

2.3 Signs on the machine 32

2.3.2 Information decals 36

2.3.3 Type plate 43

2.4 Safety instructions 43

2.41 General safety instructions 43

2.4.2 Instructions on preventing crushing injuries and burns 45

2.4.3 Instructions on preventing fires and explosions 45

2.44 Safety instructions for start-up 46

2.45 Safety precautions during start-up 46

2.46 Instructions for safe working 46

2.4.7 Safety instructions for driving on slopes 48

2.4.8 Parking safely 48

2.49 Transporting the machine safely 48

2.410 Towing the machine safely 49

2.411 Measures for ensuring safe maintenance 49

2.412 Safety instructions for maintenance work on machines with hydro

accumulators 52

2.413 Safety instructions for welding work on the machine 52

2.4.14 Instructions for working safely on the attachment 52

2.4.15 Safety instructions for transporting the machine by crane 53

2.4.16 Safe maintenance of hydraulic hoses and hose lines 53

2.4.17 Roll-over protection structure (ROPS) and falling object protection

structure (FOPS) 54

2.4.18 Attachments and accessories 54

2.4.19 Protection against vibrations 55

2.420 See and be seen 55

3 Handling and operation 57

3.1 Control elements 57

3.1.1 Operator’s cab 57

3.1.2 Display 58

3.1.3 Control unit 58

3.1.4 Switches/buttons 60

3.1.5 Control lever 61

3.2 Handling 62

3.2.1 Battery main switch 82

3.2.10 Control panel 77

3.2.11 Start switch 78

3.2.12 Steering column switch 79

3.2.13 Lighting 80

3.2.14 Interior lighting of the driver’s cab 83

3.2.15 LC display 84

3.2.16 Touch screen display 87

3.2.17 Control lever 100

3.2.18 Controlling a working attachment with an independent hydraulic circuit 102

3.2.19 Heating, ventilation, air conditioning 105

3.2.20 Rear window heater and mirror heater (optional) 108

3.2.21 Interior and exterior mirrors 108

3.2.22 Sun visor 109

3.2.23 Radio 109

3.2.24 Windscreen wiper and washer system 110

3.2.25 Liebherr automatic central lubrication system 112

3.2.26 Back-up alarm 115

3.2.27 Reversible fan drive 116

3.2.28 LiDAT 117

3.3.1 Daily start-up 118

3.4.1 Picking up material 146

3.5.1 Removing the working attachment from the quick-change device 155

3.6.1 Transporting the machine 161

3.7.1 Lowering the lift arms if the engine fails 165

4.1 Servicecodes 175

4.1.1 Service code indicator in the display 175

421 Warning symbols 180

4.3.1 Replacing fuses 182

5.1 Maintenance and inspection schedule 187

5.2 Filling quantities and lubrication chart 192

52.1 Recommended lubricants 192

5.2.3 Lubrication chart 193

5.3 Lubricants and fuels 197

5.3.1 General information on changing lubricants and fuels 197

harmless hydraulic fluids 197

5.3.3 Diesel fuels 198

5.3.4 Lubricating oils for diesel engines 199

5.3.5 Coolants for diesel engines 201

5.3.6 Hydraulic oil 203

5.3.7 Lubricating oils for splitter boxes 207

5.3.8 Lubricating oils for transmissions 208

5.3.9 Lubricating oils for axles 208

5.3.10 Lubrication grease and other lubricants 209

5.4 Safety precautions 21

5.5 Preparatory tasks for maintenance 212

5.5.1 Maintenance positions 212

5.5.2 Opening the service accesses 213

5.5.3 Turning off the battery main switch 215

5.6 Overall machine 217

5.6.1 Checking the machine for external damage 217

5.6.2 Removing loose parts, dirt, ice and show from the machine 217

5.6.3 Cleaning the machine 217

5.6.4 Shutting down the machine for a lengthy period 219

5.6.5 Deactivating the machine 219

5.6.6 Checking the machine for leaks 219

56.7 Making sure the bolted connections are tight 220

fertilisers and exchanging VCI capsules 220

5.6.9 Oil analyses 220

5.7 Drive group 227

5.7.1 Checking the engine oil level 227

5.7.2 Draining off condensate and sediment from the fuel tank 227

5.7.3 Draining off condensate from the Separ fuel pre-filter 228

5.7.4 Draining off condensate from the fuel pre-filter 229

5.7.5 Changing the Separ fuel pre-filter insert 23

5.7.7 Changing the fuel fine filter 233

5.7.8 Bleeding the fuel system 234

5.7.9 Cleaning the air filter service cover and dust discharge valve 234

5.7.10 Cleaning or changing the main filter element 235

5.7.11 Changing the air filter safety element 238

5.7.12 Checking the oil level in the splitter box 239

Cooling system 241

5.8.1 Checking the coolant level 241

5.8.2 Checking the coolant antifreeze and corrosion inhibitor concentration 242

5.8.3 Cleaning the cooling system 246

Working hydraulics 248

5.9.1 Checking the oil level in the hydraulic tank 248

Steering system 250

5.10.1 Testing the steering 250

5.10.2 Lubricating the bearing points on the steering cylinders 250

Brake system 251

5.11.1 Testing the service brake and parking brake 251

Electrical system 253

5.12.1 Checking the lights 253

Transmission 254

5.13.1 Checking the transmission oil level 254

Axles and cardan shafts 255

5.14.1 Checking the tyre pressure 255

5.14.2 Checking the wheel tightness 255

Steel components of the basic machine 257

5.15.1 Lubricating the articulated bearing and the rear oscillating bedding 257

5.15.2 Covering – lubricating locks and hinges 257

5.16.3 Greasing the rear section cover lower hinges 258

Working attachment 259

5.16.1 Lubricating the lift arms and attachment 259

5.16.2 Checking the bucket bearing seals and the bearing bushings on the lift

5.16.3 Lubricating and testing the quick-change device 262

5.17.2 Changing the fresh and recirculated air filters 265

5.17.3 Checking the condition and function of the safety belt 266

5.17.4 Checking and topping up the windscreen washer reservoir 266

5.17.5 Checking the seals on the driver’s cab 267

5.18 Lubrication system 269

5.18.1 Checking the lubrication system grease reservoir level 269

5.18.2 Checking the pipes, hoses and lubrication points of the lubrication

system 269

5.18.3 Checking whether metered quantities are adequate at the bearing

points (grease collars) of the lubrication system 270

Index 271

VIDEO PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the SAME exact manual used by your dealers to fix your vehicle.

- The same can be yours in the next 2-3 mins as you will be directed to the download page immediately after paying for the manual.

- Any queries / doubts regarding your purchase, please feel free to contact [email protected]

S.V