Liebherr L 556 1288 Wheel Loader Service Manual – PDF DOWNLOAD

FILE DETAILS:

Liebherr L 556 1288 Wheel Loader Service Manual – PDF DOWNLOAD

Language : English

Pages : 814

Downloadable : Yes

File Type : PDF

Size: 186 MB

DESCRIPTION:

Liebherr L 556 1288 Wheel Loader Service Manual – PDF DOWNLOAD

- This service manual is designed for trained specialist staff of the Liebherr organisation and their dealers.

- This service manual contains specialist knowledge for repairing Liebherr construc- tion machines. Basic specialist knowledge on electronics, hydraulics, mechanics and engine technology is not contained in this service manual. Therefore special- ized training and qualifications are necessary. Liebherr recommends participating in the Liebherr training program for construction machines.

In this service manual you will find information on:

- You will find information on controls and operation in the operator’s manual. Information on spare parts are in the spare parts catalogue. Please observe the local accident prevention laws.

- You can find information on repairs of machine parts in the service documentation under “Wheel loader – repair instructions”.

Safety instructions

General safety instructions

1. Familiarise yourself with the operator’s manual before starting up the

machine.

Make sure that you are in possession of additional instructions for any special

equipment installed on your machine, and that you have read and understood

them.

2. Only expressly authorised personnel may operate, service or repair the

machine.

Observe the legal minimum ages.

3. Only trained or instructed personnel may operate the machine. Clearly assign

responsibility for operation, rigging, maintenance and repair work.

4. The operator of the machine must ensure that no persons are in the operating

area of the machine on the basis of a risk assessment conducted in respect of

the operating site.

5. Clearly establish the driver’s responsibilities (also with respect to traffic regulations)

and authorise him to refuse to carry out unsafe instructions from third

parties.

6. Personnel undergoing training and instruction, or who are not yet fully qualified,

may only be allowed to work on the machine under constant supervision

by an experienced person.

7. Now and again, check that your personnel are working safely and are aware of

possible dangers in observance of the operator’s manual.

8. Wear safe working clothes when working on the machine.

Do not wear rings, wristwatches, ties, scarves, unbuttoned jackets, loose

clothing or similar garments, as they can become caught in the machinery and

cause injury.

Certain tasks require: safety glasses, safety boots, hard hats, protective

gloves, reflective vests, ear protection etc.

9. Ask the site manager about any special safety regulations in force on the

construction site.

10. Do not hold onto the steering column, the control panel or the control levers

when getting on or off the machine.

You might inadvertently trigger movements which could lead to accidents.

11. Never jump down from the machine. Use the steps, ladders and platforms

provided for getting on and off.

12. Keep all handles, steps, rails, gangways, platforms and ladders free from oil,

grease, mud snow and ice. This reduces the risk of slipping, tripping up or

falling.

13. Familiarise yourself with the emergency exit through the right cab door and/or

the rear window.

14. Unless there are other instructions, perform maintenance and repair work as

follows:

Procedure:

• Park the machine on firm, level ground and lower the working attachment

to the ground.

• Move all control levers to neutral.

• Turn off the diesel engine and take out the ignition key.

15. Before all work on the hydraulic system, depressurise the hydraulic circuits

and the hydraulic tank as described in the operator’s manual.

16. Lock the working hydraulics to prevent accidental actuation before leaving the

operator’s seat.

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Liebherr L 556 1288 Wheel Loader Service Manual – PDF DOWNLOAD

010.1 Safety instructions 010-4

0101.1 General safety instructions 010-4

010.1.2 Instructions on preventing crushing injuries and burns 010-5

010.1.3 Instructions on preventing fires and explosions 010-5

010.14 Safety instructions for start-up 010-6

0101.5 Safety precautions during start-up 010-6

010.1.6 Instructions for safe working 010-7

010.1.7 Safety instructions for driving on slopes 010-8

0101.8 Parking safely 010-8

010.1.9 Transporting the machine safely 010-8

010.1.10 Towing the machine safely 010-9

010.1.11 Measures for ensuring safe maintenance 010-9

010.1.12 Safety instructions for maintenance work on machines with hydro

accumulators 010-12

010.1.13 Safety instructions for welding work on the machine 010-12

010.1.14 Safety instruction for working on the working attachment 010-12

010.1.15 Safety instructions for transporting the machine by crane 010-13

010.1.16 Safe maintenance of hydraulic hoses and hose lines 010-13

010.1.17 Roll over protective structure (ROPS) and falling object protection

structure (FOPS) 010-14

010.1.17.1 Preventing accidents 010-14

010.1.17.2 Preventing injuries 010-14

010.1.18 Attachments and accessories 010-14

010.1.19 Protection against vibrations 010-15

010.1.20 See and be seen 010-15

010.1.20.1 Field of view and visual aids 010-15

010.1.20.2 Measures during operation. 010-16

010.1.20.3 Modifications to the machine 010-16

010.1.21 Danger area of the machine 010-17

010.2.1 Special tools in general 010-18

010.2.2 Special tools for Liebherr diesel engines 010-19

010.2.3 Special tools, hydraulic cylinder (Z kinematics) 010-20

010.2.4 Special tools, hydraulic cylinder (industrial machine) 010-20

010.2.56 Special tools for steering cylinders 010-21

010.2.6 Special tools for the electrical system 010-21

010.2.7 Special tools for the transmission 010-21

010.2.8 Special tools for front axle MT-L II 010-22

010.29 Special tools for rear axle MT-L II 010-22

010.2.10 Special tools for the air conditioning system 010-22

010.2.11 Special tools for Grammer driver’s seat 010-23

010.2.12 Special tools for cab glazing 010-23

010.2.13 Special tools for the central lubrication system (Liebherr) 010-23

010.2.14 Special tools for the central lubrication system (Groeneveld) 010-24

Standards and regulations 010-25

010.3.1 Prestressing forces and tightening torques for bolts with metric

010.3.1.1 Range of application and purpose 010-25

010.3.1.2 Other applicable documents 010-25

010.3.1.3 Modifications and descriptions 010-26

010.3.1.4 Tightening torques 010-26

010.3.2 Liebherr standards for assembly instructions and tightening torques010-32

Preservation guidelines 010-33

010.4.1 General information 010-33

010.4.2 Machine out of service for an unknown period of time 010-33

010.4.3 Putting the machine out of service 010-34

010.4.3.1 Out of service for up to 2 months 010-34

0104.3.2 Out of service for up to 12 months 010-35

0104.3.3 Out of service for longer than 12 months 010-36

010.4.4 Putting back into service 010-36

020.1 Overall machine 020-6

0201.1 Complete machine with bucket (Z lift arms)

L556-1288/25344-; 020-6

0201.2 Complete machine with bucket (industrial lift arms)

L556-1288/25344-; 020-7

020.1.3 Attachment: Light material bucket

L556-1288/25344-; 020-9

020.14 Attachment: High dump bucket

L556-1288/25344-; 020-11

0201.5 Attachment: Forklift

L556-1288/25344-; 020-12

020.1.6 Attachment: Timber grabber

L556-1288/25344-; 020-14

020.2 Drive group 020-16

020.2.1 Diesel engine

L556-1288/25344-; 020-16

0202.2 Diesel particulate filter temperature sensors

L556-1288/25344-; 020-17

020.2.3 Fuel tank

L556-1288/25344-; 020-18

020.24 Fuel pre-filter (separator filter)

L556-1288/25344-; 020-18

020.2.5 Fuel fine filter

L556-1288/25344-; 020-18

0202.6 Air filter vacuum switch

L556-1288/25344-; 020-18

020.2.7 Clutch

L556-1288/25344-; 020-19

0202.8 Splitter box

L556-1288/25344-; 020-19

020.3 Cooling system 020-20

020.3.1 Fan gear pump

L556-1288/25344-; 020-20

020.3.2 Fan gear motor

L556-1288/25344-; 020-20

020.3.3 Hydraulic oil temperature sensor B8

L556-1288/25344-; 020-20

020.4 Working hydraulics 020-21

020.4.1 Working hydraulics pump

L556-1288/25344-; 020-21

0204.2 Control valve block

L556-1288/25344-; 020-21

020.4.4 Pilot control hydro accumulator

020.4.5 Stabilisation module

020.4.6 Ride control hydro accumulator

020.4.7 Z kinematics and industrial lift arms lift cylinder

020.4.8 Z kinematics tilt cylinder

020.4.9 Industrial lift arms tilt cylinder

Travel hydraulics 020-24

020.5.1 Travel pump

020.5.2 Travel motor 1

020.5.3 Travel motor 2

020.5.4 Variable displacement motor scavenging gear pump

Hydraulic components 020-26

020.6.1 Filter unit

020.6.2 Breather filter

Steering system 020-27

020.7.1 Steering pump

020.7.2 Servostat

020.7.3 Steering cylinder

020.7.4 Steering cylinder pressure relief valve

020.7.5 Steering damper hydro accumulator

020.7.6 Emergency steering pump

020.7.7 Emergency steering pressure switch B3

L556-1288/25344-; 020-29

020.8 Brake system 020-30

0208.1 Brake system gear pump

L556-1288/25344-; 020-30

020.8.2 Compact brake valve

L556-1288/25344-; 020-30

0208.3 Service brake hydro accumulator

L556-1288/25344-; 020-30

020.8.4 Brake light pressure switch B12

L556-1288/25344-; 020-30

0208.5 Accumulator charge pressure switch B19

L556-1288/25344-; 020-31

020.8.6 Parking brake hydro accumulator

L556-1288/25344-; 020-31

0208.7 Overspeed protection solenoid valve Y16

L556-1288/25344-; 020-31

020.9 Electrical system 020-32

0209.1 Central control unit (Master 4)

L556-1288/25344-; 020-32

020.9.2 Input module

L556-1288/25344-; 020-32

020.9.3 Output module

L556-1288/25344-; 020-32

020.94 Battery

L556-1288/25344-; 020-33

0209.5 Voltage transformer

L556-1288/25344-; 020-33

020.9.6 Reversing camera

L556-1288/25344-; 020-33

020.10 Gearbox 020-35

020.10.1 Transmission

L556-1288/25344-; 020-35

3 020.10.2 Gear shifting solenoid valves

8 L556-1288/25344-; 020-36

a

8 020.10.3 Speed sensors

g L556-1288/25344-; 020-36

§ 020.10.4 Transmission gear pump

§ L556-1288/25344-; 020-36

: 020.11 Axles and drive shafts 020-37

3 020.11.1 Front axle

L556-1288/25344-; 020-37

020.112 Rear axle

L556-1288/25344-; 020-37

020.11.4 Rear drive shaft

L556-1288/25344-; 020-38

020.11.5 Tyres

L556-1288/25344-; 020-38

020.11.5.2 Tyres for timber handling 020-39

020.11.5.3 Special tyres 020-40

020.11.5.4 Tyres for machines with optional accessories 020-40

020.12 Steel parts of the basic machine 020-42

020.12.1 Ballast weight

L556-1288/25344-; 020-42

020.13 Working attachment 020-43

020.13.1 Lift arms with Z kinematics

L556-1288/25344-; 020-43

020.13.2 Industrial machine lift arms

1 556-1288/25344-; 020-44

020.14 Operator’s cab, heating and air conditioning 020-45

020.14.1 Heating, air conditioning

1 556-1288/25344-; 020-45

020.14.2.1 Air conditioning 020-45

020.14.3.1 Air conditioning compressor 020-45

020.14.4 Condenser

L556-1288/25344-; 020-45

020.14.5 Dryer

1 556-1288/25344-; 020-46

020.14.6 Air conditioning pressure switch

L556-1288/25344-; 020-46

020.14.7 Anti-icing temperature sensor

1 556-1288/25344-; 020-46

020.15 Lubrication system 020-48

020.15.1 Central lubrication system (Liebherr)

L556-1288/25344-; 020-48

020.15.1.1 Central lubrication pump 020-48

020.15.1.2 Progressive distributor 020-48

030 Maintenance 030-1

030.1 Maintenance and inspection schedule 030-10

030.2 Filling quantities and lubrication chart 030-15

030.2.1 Recommended lubricants

1 556-1288/25344-; 030-15

030.2.2 Recommended operating fluids

L556-1288/25344-40348; 030-16

0302.3 Recommended operating fluids

L556-1288/40349-; 030-16

030.3 Lubricants and fuels 030-17

030.3.1 General information on lubricants and fuels 030-17

030.3.1.1 General questions 030-17

030.3.1.2 Safety data sheets 030-17

030.3.1.3 Technical data sheets 030-17

030.3.1.4 Specific Liebherr standards 030-17

030.3.2 General information on changing lubricants and fuels 030-17

030.3.3 Converting hydraulic system from mineral oils to biodegradable

hydraulic fluids 030-18

030.3.4 Diesel fuels

L556-1288/25344-; 030-18

030.3.4.1 Specification 030-18

030.3.4.2 Sulphur content of the diesel fuel, lubricity 030-18

030.3.4.3 Diesel fuel at low temperatures (winter operation) 030-19

030.3.4.4 Flow improvers at low temperatures 030-19

030.3.5 Diesel fuels for diesel engines without emission-type approval

L556-1288; 030-19

030.3.5.1 Minimum quality requirement 030-19

030.3.6 Lubricating oils for diesel engines

L556-1288/25344-; 030-20

030.3.6.1 Lubricating oil quality 030-20

030.3.6.2 Lubricating oil viscosity 030-20

030.3.6.3 Complicating factors affect the oil change 030-21

030.3.7 Engine oils for diesel engines without emission-type approval

L 556-1288; 030-21

030.3.7.1 Liebherr recommendation 030-21

030.3.7.2 Other approved engine oils 030-21

030.3.7.3 Minimum quality requirement 030-22

030.3.7.4 Changing intervals 030-22

030.3.7.5 Complicating factors 030-22

030.3.8 Refrigerant

1556-1288; 030-22

030.3.9 Coolants for diesel engines

1 556-1288/25344-40348; 030-23

030.3.9.1 General recommendations 030-23

030.3.9.2 Water (fresh water) 030-23

030.3.9.3 Coolant mixing ratio 030-23

030.3.9.4 Permissible antifreeze and corrosion inhibitors 030-24

030.3.9.5 Corrosion inhibitors without antifreeze 030-24

030.3.10 Coolants for diesel engines

1 556-1288/40349-; 030-25

030.3.10.1 General recommendations 030-25

030.3.10.2 Water (fresh water) 030-25

030.3.10.3 Coolant – Mixing ration 030-26

030.3.10.4 Approved antifreeze and corrosion inhibitors 030-26

030.3.10.56 Permissible premixed antifreeze/corrosion inhibitors 030-26

030.3.10.6 Corrosion inhibitors without antifreeze 030-27

030.3.11 Hydraulic oil

1 556-1288/25344-; 030-27

030.3.11.1 Liebherr hydraulic oil 030-28

030.3.11.2 Using engine oil as hydraulic oil 030-28

030.3.11.3 Warming up 030-29

030.3.11.4 Biodegradable hydraulic oils 030-29

030.3.11.5 Changing the oil, analysing the oil, changing filters (030-30

030.3.12 Lubricating oils for splitter boxes

L556-1288/25344-; 030-31

030.3.13 Lubricating oils for transmissions

L556-1288/25344-; 030-32

030.3.14 Lubricating oils for axles

1 556-1288/25344-; 030-33

030.3.15 Lubrication grease and other lubricants

1 556-1288/25344-; 030-33

030.3.15.1 Minimum quality requirements 030-34

030.3.15.2 Liebherr lubrication grease 030-34

030.4 Maintenance tasks 030-36

030.4.1 Safety precautions

1 556-1288/25344-; 030-36

030.4.2 Preparatory tasks for maintenance 030-36

030.4.2.1 Maintenance positions

L556-1288/25344-; 030-37

030.4.2.2 Opening the service accesses

1L.556-1288/25344-; 030-38

030.4.2.3 Turning off the battery main switch

L556-1288/25344-; 030-40

030.4.3.1 Checking the machine for external damage

L556-1288/25344-; 030-41

030.4.3.2 Removing loose parts, dirt, ice and snow from the

machine

L556-1288/25344-; 030-41

030.4.3.3 Cleaning the machine

L556-1288/25344-; 030-41

030.4.3.4 Checking the machine for leaks

L556-1288/25344-; 030-43

030.4.3.5 Making sure the bolted connections are tight

L556-1288/25344-; 030-43

030.4.3.6 Corrosion protection system for use with salt and arti-

ficial fertilisers (optional): Carrying out corrosion

protection

L556-1288/25344-; 030-43

030.4.3.7 Qil analyses

L556-1288/25344-; 030-44

0304.4 Drive group 030-50

030.4.4.1 Checking the engine oil level

L556-1288/25344-; 030-50

030.4.4.2 Changing diesel engine oil

1 556-1288/25344-; 030-51

030.4.4.3 Changing the engine oil filter

L556-1288/25344-; 030-52

030.4.4.4 Checking the V-ribbed belt on the engine

L556-1288/25344-; 030-53

030.4.4.5 Changing the V-ribbed belt on the engine

L556-1288/25344-; 030-53

030.44.6 Checking the mounting and sensor cable connec-

tions of the engine control units

L556-1288/25344-; 030-55

030.4.4.7 Checking the engine valve clearance

L556-1288/25344-; 030-55

030.44.8 Diesel engine oil separator – changing filter cartridge

L556-1288/25344-; 030-57

030.4.4.9 Checking the engine heating flange

L556-1288/25344-; 030-58

030.4.4.10 Changing the engine heating flange

L556-1288/25344-; 030-59

030.4.4.11 Draining off condensate and sediment from the fuel

tank

1 556-1288/25344-; 030-59

030.4.4.12 Draining off condensate from the Separ fuel pre-filter

L556-1288/25344-; 030-60

030.4.4.14 Changing the fuel fine filter

030.4.4.15 Bleeding the fuel system

030.4.4.16 Cleaning the air filter service cover and dust

030.4.4.17 Checking the air suction system for leaks and tight

030.4.4.18 Cleaning or changing the main filter element

030.4.4.19 Changing the air filter safety element

030.4.4.20 Checking the oil level in the splitter box

030.4421 Changing the splitter box oil

030.4.4.22 Checking the exhaust system for leaks and tight

030.4.4.23 Cleaning or changing the diesel particulate filter

Cooling system 030-80

030.4.5.1 Checking the coolant antifreeze and corrosion inhib-

030.4.5.2 Cleaning the cooling system

0304.5.3 Changing the coolant

0304.5.4 Changing the coolant

Working hydraulics 030-90

030.4.6.1 Lubricating the solenoids, universal joints and

Hydraulic components 030-90

030.4.7.1 Checking the oil level in the hydraulic tank

0304.7.2 Checking and cleaning the magnetic rod on the

hydraulic tank

030.4.7.4 Changing the hydraulic tank return suction filter

L556-1288/25344-; 030-94

030.4.7.5 Changing the hydraulic tank breather filter

L556-1288/25344-; 030-95

030.4.7.6 Hydraulic tank – changing the oil in the hydraulic

system

L556-1288/25344-; 030-96

0304.8 Steering system 030-97

030.4.8.1 Testing the steering

L556-1288/25344-; 030-97

030.4.8.2 Lubricating the bearing points on the steering cylin-

ders

L556-1288/25344-; 030-98

0304.9 Brake system 030-98

030.4.9.1 Testing the service brake and parking brake

L556-1288/25344-; 030-98

030.4.9.2 Checking the service brake discs for wear

L556-1288/25344-; 030-99

030.4.9.3 Checking the gap and wear on the parking brake

linings

L556-1288/25344-; 030-102

0304.10 Electrical system 030-107

030.4.10.1 Checking the lights

L556-1288/25344-; 030-107

030.4.10.2 Checking the batteries, fluid level and terminals

1 556-1288/25344-; 030-108

030.4.10.3 Changing the travel direction rocker switch and cap

(optional) on the control lever

L556-1288/25344-; 030-110

030.4.11 Gearbox 030-112

030.4.11.1 Checking the transmission oil level

1 556-1288/25344-; 030-112

030.4.11.2 Changing the transmission oil

L556-1288/25344-; 030-113

030.4.11.3 Changing the transmission oil filter

L556-1288/25344-; 030-114

030.4.12 Axles and drive shafts 030-115

030.4.12.1 Checking the axle oil levels

L556-1288/25344-; 030-115

030.4.12.2 Changing the axle oil

L556-1288/25344-; 030-115

030.4.12.3 Checking the cardan shafts

L556-1288/25344-; 030-117

0304.124 Checking the tyre pressure

1L.556-1288/25344-; 030-117

030.4.12.5 Checking the wheel tightness

L556-1288/25344-35541; 030-117

030.4.12.6 Checking the wheel tightness

L556-1288/35542-; 030-118

030.4.13 Steel parts of the basic machine 030-119

030.4.13.1 Lubricating the articulation bearing and the rear axle

oscillating bearing

L556-1288/25344-; 030-119

030.4.13.2 Covering – lubricating locks and hinges

L556-1288/25344-; 030-120

030.4.13.3 Greasing the rear section cover lower hinges

L556-1288/25344-; 030-120

030.4.14 Working attachment 030-121

030.4.14.1 Lubricating the lift arms and attachment

L556-1288/25344-; 030-121

030.4.14.2 Checking the bucket bearing seals and the bearing

bushings on the lift arms

L556-1288/25344-; 030-122

030.4.14.3 Checking the lift arm bucket stops

1L.556-1288/25344-; 030-124

030.4.14.4 Lubricating and testing the quick-change device

L556-1288/25344-; 030-125

030.4.15 Operator’s cab, heating and air conditioning 030-126

030.4.15.1 Lubricating the elongated hole on the accelerator

pedal and checking the bearing

1L.556-1288/25344-; 030-126

0304.15.2 Cleaning the fresh and recirculated air filters

L556-1288/25344-; 030-127

030.4.15.3 Changing the fresh and recirculated air filters

1L556-1288/25344-; 030-129

030.4.154 Checking the condition and function of the safety belt

L556-1288/25344-; 030-130

030.4.15.5 Checking and topping up the windscreen washer

reservoir

L556-1288/25344-; 030-130

030.4.1568 Lubricating the cab door hinges

L556-1288/25344-; 030-131

030.4.15.7 Checking the seals on the driver’s cab

1L.556-1288/25344-; 030-131

030.4.15.8 Heating and air conditioning unit: Testing the function

1L556-1288/25344-; 030-131

030.4.16 Lubrication system 030-133

030.4.16.1 Checking the lubrication system grease reservoir

level

L556-1288/25344-; 030-133

the lubrication system

L556-1288/25344-; 030-134

at the bearing points (grease collars) of the lubrica-

L556-1288/25344-; 030-134

030.5 Testing and adjustment checklist

L556-1288/25344-; 030-135

030.6 Testing and adjustment tasks 030-140

0306.1 Safety precautions

L556-1288/25344-; 030-140

030.6.2 Overall machine 030-141

030.6.2.1 Preparatory tasks for testing and adjustment

L556-1288/25344-; 030-141

030.6.2.2 Bringing the machine up to operating temperature

1 556-1288/25344-; 030-142

030.6.3 Drive group 030-143

030.6.3.1 Calibrating the pedals

L556-1288/25344-; 030-143

030.6.3.2 Checking the engine speed

L556-1288/25344-; 030-143

030.6.3.3 Engine: Reading the service files

1 556-1288/25344-; 030-144

030.6.3.4 Diesel particulate filter: Performing service regenera-

tion.

L556-1288/25344-; 030-145

0306.4 Cooling system 030-147

030.6.4.1 Fan gear motor proportional pressure relief valve

1 556-1288/25344-; 030-147

0306.5 Working hydraulics 030-149

030.6.5.1 Working hydraulics pump flow regulator (standby

pressure)

L556-1288/25344-; 030-149

030.6.5.2 Working hydraulics pump, flow regulator (differential

pressure)

L556-1288/25344-; 030-151

1 556-1288/25344-; 030-152

030.6.5.5 Z kinematics control valve block primary pressure

030.6.5.6 Z kinematics control valve block LS pressure cut-off

0306.5.7 Industrial lift arm control valve block secondary pres-

030.6.5.8 Industrial lift arm control block, primary pressure

030.6.5.9 Industrial lift arms control valve block LS pressure

030.6.5.10 Stabilisation module cut-off function

030.6.5.11 Nitrogen filling of ride control hydro accumulator

0306.5.12 Testing the Z kinematics control valve block for

Hydraulic components 030-167

030.6.6.1 Checking the hydraulic lines for damage

Travel hydraulics 030-172

0306.71 Travel pump, high pressure sensor

030.6.7.2 Travel pump replenishing pressure relief valve

030.6.7.3 Pressure relief and replenishing valves of the travel

030.6.7.4 Travel pump pressure cut-off

030.6.7.5 Travel pump block curve calibration

030.6.7.6 Travel motors, automatic calibration

030.6.7.7 Engine output

Steering system 030-183

Steering pump flow regulator (standby pressure)

Steering pump flow regulator (differential pressure)

L556-1288/25344-; 030-185

030.6.9.2 Service brake pressure

030.6.9.3 Service brake hydro accumulator capacity

030.6.9.4 Accumulator charge pressure switch shift pressure

Electrical system 030-191

030.6.10.1 Central control unit (Master4) Creating a Servicefile

030.6.10.2 Central control unit (Master4); software update

030.6.10.3 Setting the IP addresses of the central control unit

030.6.10.4 Resetting the central control unit (Master4)

030.6.10.5 Testing the CAN line

030.6.10.6 Addressing the CAN module and checking the

Gearbox 030-208

030.6.11.1 Control valve block shift pressure

030.6.11.2 Nitrogen filling of transmission hydro accumulator

Operator’s cab, heating and air conditioning 030-210

030.6.12.1 Checking the pressure and temperature conditions of

030.6.12.2 Calibrating the display (Display4)

030.6.12.3 Formatting the display and reinstalling the software

030.6.13.1 Checking the LiDAT connection status

1.556-1288/25344-; 030-214

030.6.13.2 LiDAT: activating data transmission manually

L556-1288; 030-216

040 Drive group 040-1

040.1 Engine 040-3

040.1.1 Diesel engine overview

L556-1288/25344-; 040-3

040.1.2 Electrical components on the engine

1 556-1288/25344-; 040-7

040.1.3 Speed sensor for crankshaft

L556-1288/25344-; 040-8

040.1.4 Camshaft speed sensor

L556-1288/25344-; 040-9

040.1.5 Fuel system 040-10

040.1.5.1 Overview of the fuel system

L556-1288/25344-; 040-11

040.1.5.2 Fuel level sensor

1L556-1288/25344-; 040-12

040.1.6 Air filter system 040-12

040.1.6.1 Air filter

L556-1288/25344-; 040-13

040.1.6.2 Vacuum switch

1 556-1288/25344-; 040-14

040.1.7 Exhaust system 040-14

040.1.7.1 Overview of the diesel particulate filter

1L.556-1288/25344-; 040-15

040.1.7.2 Diesel oxidation catalyst (DOC)

L556-1288/25344-; 040-20

040.1.7.3 Diesel particulate filter module

1L.556-1288/25344-; 040-21

040.1.7.4 Removing the diesel particulate filter

L556-1288; 040-21

040.1.7.5 Installing the diesel particulate filter

1556-1288; 040-23

040.2 Clutch

L556-1288/25344-; 040-27

040.3 Splitter box

L556-1288/25344-; 040-29

050.1 Overview of the cooling system

L556-1288/25344-; 050-2

050.2 Cooling system hydraulics 050-3

0502.1 Overview of the hydraulics cooling system

L556-1288/25344-; 050-3

050.2.2 Fan gear pump

L556-1288/25344-; 050-5

050.2.3 Fan gear motor

L556-1288/25344-; 050-7

050.3 Cooling system electronics 050-11

050.3.1 Electric fan speed control

L556-1288/25344-; 050-11

050.3.2 Hydraulic oil temperature sensor

L556-1288/25344-; 050-13

060 Working hydraulics 060-1

060.1 Overview of the working hydraulics

L556-1288/25344-; 060-2

060.2 Pilot control 060-9

060.2.1 Pilot control unit

L556-1288/25344-; 060-9

060.2.2 Pilot control solenoid valve

L556-1288/25344-; 060-14

060.2.3 Pilot control hydro accumulator

L556-1288/25344-; 060-15

060.3 Ride control 060-16

060.3.1 Stabilisation module

L556-1288/25344-; 060-16

060.3.2 Ride control hydro accumulator

L556-1288/25344-; 060-20

060.4 Hydraulic cylinders of the working hydraulics 060-21

060.4.1 Hydraulic cylinders for Z kinematics 060-21

060.4.1.1 Z kinematics lift cylinder

L556-1288/25344-; 060-21

060.4.1.2 Z kinematics tilt cylinder

L556-1288/25344-; 060-22

060.4.2 Hydraulic cylinders for industrial lift arms 060-23

060.4.2.1 Lift cylinder for industrial lift arms

L556-1288/25344-; 060-23

060.4.2.2 Industrial lift arms tilt cylinder

L556-1288/25344-; 060-24

070.1 Travel hydraulics overview

1 556-1288/25344-38936; 070-2

070.2 Travel hydraulics overview

L556-1288/38937-; 070-10

070.3 Variable displacement pump

L556-1288/25344-; 070-14

Hydraulic components 080-1

080.1 Hydraulic tank 080-2

080.1.1 Overview of the hydraulic tank

L556-1288/25344-; 080-2

080.1.2 Filter unit

1 556-1288/25344-; 080-5

080.1.3 Breather filter

1 556-1288/25344-; 080-10

Steering system 090-1

090.1 Steering system overview

L556-1288/25344-34309; 090-2

090.2 Steering system overview

L556-1288/34310-35231; 090-8

090.3 Steering system overview

L556-1288/35232-; 090-14

090.4 Steering pump

L556-1288/25344-; 090-17

090.5 Servostat

L556-1288/25344-; 090-24

090.6 Steering cylinder 090-29

090.6.1 Steering cylinder overview

L556-1288/25344-; 090-29

090.6.2 Steering cylinder pressure relief valve

L556-1288/34310-; 090-31

090.6.3 Steering damper hydro accumulator

1 556-1288/25344-; 090-32

090.7 Emergency steering 090-34

090.7.1 Emergency steering overview

1 556-1288/25344-; 090-34

090.7.2 Emergency steering pump

L556-1288/25344-; 090-38

090.7.3 Emergency steering electronics 090-40

090.7.3.1 Emergency steering pressure switch

090.7.4 Valve block

L556-1288/25344-; 090-43

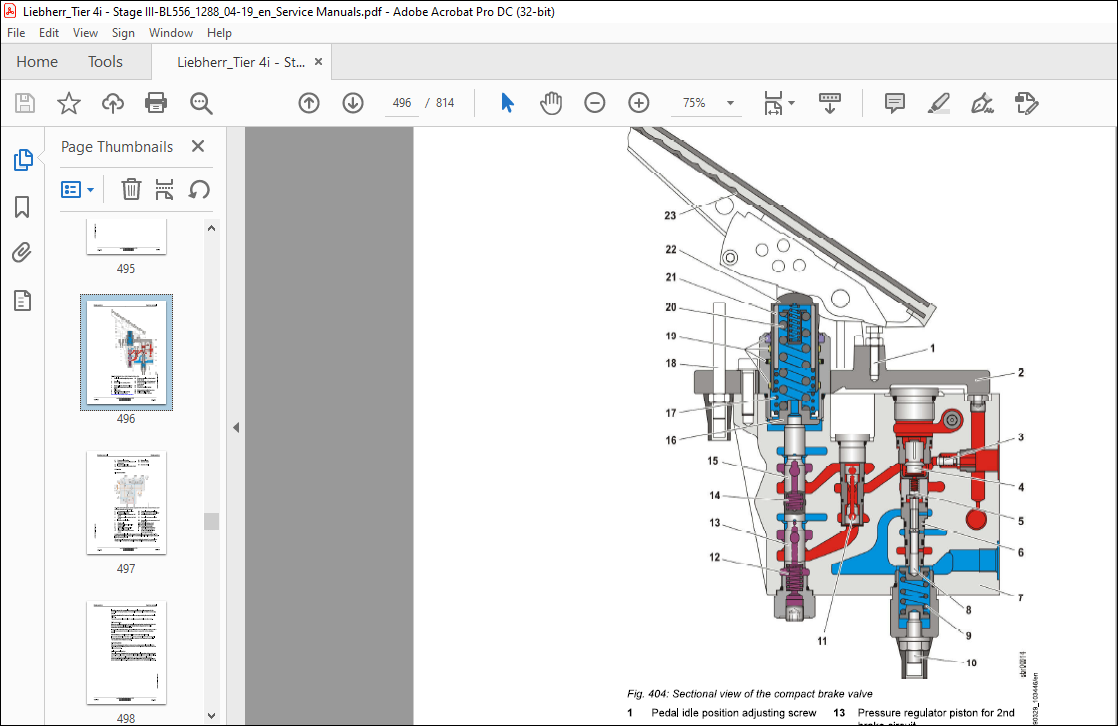

100 Brake system 100-1

100.1 Overview of the brake system

L556-1288/25344-; 100-2

100.2 Service brake and parking brake 100-9

100.2.1 Compact brake valve

L556-1288/25344-; 100-9

100.3 Service brake 100-13

100.3.1 Service brake hydro accumulator

L556-1288/25344-; 100-13

100.3.2 Brake light pressure switch

L556-1288/25344-; 100-14

100.3.3 Accumulator charge pressure switch

L556-1288/25344-; 100-15

100.4 Parking brake 100-16

100.4.1 Parking brake

L556-1288/25344-; 100-16

100.4.2 Disc brake

L556-1288/25344-; 100-18

100.4.3 Parking brake hydro accumulator

L556-1288/25344-; 100-21

100.6 Overspeed protection 100-22

100.5.1 Overview of the overspeed protection system

L556-1288/25344-; 100-22

100.56.2 Overspeed protection solenoid valve

L556-1288/25344-; 100-25

110 Electrical system 110-1

110.1 Overview of the electrical system

1 556-1288/25344-; 110-2

110.2 Lighting

1 556-1288/25344-; 110-7

110.3 Circuit diagrams

L556-1288/25344-; 110-9

110.4 Electronic control unit 110-11

110.4.1 Central control unit (Master4)

L556-1288/25344-; 110-11

110.4.2 Modules 110-15

copyright ® Liebherr-Werk Bischofshofen GmbH 2019

L556-1288 LIEBHERR 23

Contents Service manual

110.4.2.2 Output modules

1 556-1288/25344-; 110-18

110.5 Electrical components of the driver’s cab 110-23

110.5.1 Overview of electrical components in the cab

L556-1288/25344-; 110-23

110.5.2 Fuse and relay board

1 556-1288/25344-; 110-24

110.6 Electrical components in the rear section 110-30

110.6.1 Battery installation

L556-1288/25344-; 110-30

110.7 Rear area monitoring with camera 110-32

110.7.1 Overview of rear area monitoring with camera

L556-1288/25344-; 110-32

110.7.2 Camera

1 556-1288/25344~; 110-33

120 Gearbox 120-1

120.1 Overview of the transmission

L556-1288/25344-; 120-2

120.2 Mechanical transmission

L556-1288/25344-; 1204

120.3 Transmission hydraulics 120-10

120.3.1 Overview of the hydraulic control system

1 556-1288/25344-; 120-10

120.3.2 Transmission gear pump

1 556-1288/25344-; 120-14

120.3.3 Control valve block

L556-1288/25344-; 120-15

120.3.4 Transmission hydro accumulator

L556-1288/25344-; 120-16

120.4 Transmission electronics 120-17

120.4.1 Overview of the electronic control system

L556-1288/25344-; 120-17

120.4.2 Gear shifting solenoid valves

L556-1288/25344-; 120-19

120.4.3 Speed sensors

L556-1288/25344-; 120-20

120.44 Gear oil temperature switch

1 556-1288/25344-; 120-21

Service manual Contents

130.1 Axles 130-2

130.1.1 Front axle

L556-1288/25344-; 130-2

130.1.2 Rear axle

L556-1288/25344-; 130-7

130.2 Cardan shafts 130-8

130.2.1 Front cardan shaft

L556-1288/25344-; 130-8

130.2.2 Rear cardan shaft

L556-1288/25344-; 130-9

140 Steel parts of the basic machine 140-1

140.1 Vehicle frame 140-2

140.1.1 Articulation bearing

L556-1288/25344-; 140-2

140.1.2 Oscillating bearing

L556-1288/25344-; 140-4

140.1.3 Articulation lock

L556-1288/25344-; 140-4

140.2 Ballast weight

L556-1288/25344-; 140-6

140.3 Cab access

L556-1288/25344-; 140-7

150 Working attachment 150-1

150.1 Lift arms for Z kinematics 150-2

150.1.1 Overview of z-bar lift arm kinematics

L556-1288/25344-; 150-2

160.1.2 Pin bearing 150-3

150.1.2.1 Standard bearing

c L556-1288/25344-; 150-3

3 150.1.2.2 Bucket bearing

o L556-1288/25344-; 150-5

8

g 150.1.2.3 Removing the bucket bearing

3 L556-1288/25344-; 150-6

g 160.1.2.4 Installing the bucket bearing

s L556-1288/25344-; 150-9

£ 150.2 Quick coupler 150-12

L556-1288/25344-; 150-12

L556-1288/25344-; 150-15

160 Operator’s cab, heating and air conditioning 160-1

160.1 Overview of the cab, heating and air conditioning unit

L556-1288/25344-; 160-3

160.2 Display and control elements 160-6

160.2.1 Electrical components in the control panel 160-6

160.2.1.1 Overview of electrical components in the control

panel

L556-1288/25344-; 160-6

160.2.1.2 Control unit for main functions

L556-1288/25344-; 160-6

160.2.1.3 Electric control unit

1 556-1288/25344-; 160-8

160.2.1.4 Starter switch

L556-1288/25344-; 160-12

160.2.2 Touch screen display

1 556-1288/25344-; 160-13

160.2.3 Control lever

1 556-1288/25344-; 160-15

160.3 Heating, ventilation, air conditioning 160-18

160.3.1 Heating and air conditioning unit 160-18

160.3.1.1 Heating and air conditioning unit

1 556-1288/25344-; 160-18

160.3.1.2 Blower

L556-1288/25344-; 160-20

160.3.2 Heating/air conditioning electronics

1 556-1288/25344-; 160-21

160.4 Air conditioning 160-23

160.4.1 Air conditioning compressor

L556-1288/25344-; 160-23

160.4.2 Condenser

L556-1288/25344-; 160-24

160.4.3 Dryer

L556-1288/25344-; 160-26

160.4.4 Air conditioning pressure switch

1 556-1288/25344-; 160-27

160.4.5 Evaporator

L556-1288/25344-; 160-28

160.4.7 Automatic air conditioning 160-29

160.4.7.1 Overview of the automatic air conditioning

L556-1288/25344-; 160-29

160.4.7.2 Interior temperature sensor and air flow temperature

sensor

L556-1288/25344-; 160-31

160.4.7.3 Outside temperature sensor

L556-1288/25344-; 160-31

160.4.7.4 Sun sensor

L556-1288/25344-; 160-32

170 Lubrication system 170-1

170.1 Liebherr automatic central lubrication system 170-2

170.1.1 Overview of Liebherr automatic central lubrication system

L556-1288/25344-; 170-2

170.1.2 Liebherr central lubrication pump

L556-1288/25344-; 170-6

170.1.3 Progressive distributor MX-F

L556-1288/25344-; 170-10

190 Options 190-1

190.1 Diesel engine without emission type approval

L556-1288; 190-2

190.2 LiDAT 190-3

190.2.1 Overview of LIiDAT

L556-1288/25344-; 190-3

190.2.2 LiDAT on the machine

L556-1288/25344-; 190-5

190.3 Refuelling system

L556-1288/25344-; 190-9

190.4 Weighing device (Liebherr)

1 556-1288/25344-; 190-12

200 Diagnosis 200-1

200.1 Malfunctions 200-2

200.1.1 Service codes in the display unit 200-2

200.1.1.2 Display of service codes 200-2

200.1.1.3 Effects of a fault 200-2

200.1.1.4 Correcting an error 200-3

200.2 Troubleshooting 200-4

200.2.1 Replacing fuses 200-4

200.2.1.1 Fuses in the battery compartment 200-4

200.2.1.2 Plug-in fuses on the relay and fuse board 200-5

VIDEO PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the same manual used by the dealers to diagnose and troubleshoot your vehicle

- You will be directed to the download page as soon as the purchase is completed. The whole payment and downloading process will take anywhere between 2-5 minutes

- Need any other service / repair / parts manual, please feel free to contact [email protected] . We still have 50,000 manuals unlisted

S.V