Liebherr L 538 1268 Wheel Loader Operator’s Manual SN 34983 – PDF DOWNLOAD

FILE DETAILS:

Liebherr L 538 1268 Wheel Loader Operator’s Manual SN 34983 – PDF DOWNLOAD

Language : English

Pages : 310

Downloadable : Yes

File Type : PDF

Size: 68.1 MB

DESCRIPTION:

Liebherr L 538 1268 Wheel Loader Operator’s Manual SN 34983 – PDF DOWNLOAD

Product ID

Manufacturer: Liebherr-Werk Bischofshofen GmbH

Type: L 538

Type no.: 1268

From Serial no.: 34983

Preface:

This operating manual has been written for the driver and for the maintenance personnel of the machine.

It contains the following descriptions:

- Chapter 1: Product description

- Chapter 2: Safety regulations

- Chapter 3: Handling and operation

- Chapter 4: Malfunctions

- Chapter 5: Maintenance

This operating manual must be carefully read before initial operation and should be read and used later at regular intervals by anyone who carries out work on the machine.

Working with or on the machine includes:

- Operation, including equipping, troubleshooting during operation, removing production debris, maintenance, removing operating and auxiliary materials.

- Servicing, including maintenance, inspection, and repairs.

- Transport or loading the machine.

This manual helps the driver to become acquainted with the machine and prevents malfunctions due to incorrect operation.

Observation of the operating manual by maintenance staff:

- Increases reliability during operation.

- Extends the service life of your machine.

- Reduces repair costs and downtime.

This manual must be kept with the machine. Make sure a copy is always kept in the glove compartment of the driver’s cab.

In addition to the operating manual, follow the instructions based on existing national accident prevention and environmental protection regulations.

In addition to the operating manual and applicable national and local legal accident prevention rules, observe the recognized technical regulations for safe and correct operation.

This operating manual contains all the information you need to operate and service your machine.

- Some illustrations in this manual may show details and equipment that are different from those on your machine.

- On some pictures, protective devices and covers have been removed for a better view.

- We constantly make improvements to our machines, which means there may have been modifications to your machine which are not mentioned in this manual.

However, if you should require explanations or information, the Liebherr technical information and customer services departments will be happy to provide assistance.

Liability and warranty:

Because of the many products on offer from other manufacturers (such as fuels, lubricants, attachments, and replacement parts), Liebherr cannot test the suitability and faultless function of all third-party products in or on Liebherr products. The same applies to any effects caused by combining third-party products with Liebherr products.

- The use of third-party products together with Liebherr products is at the risk of the operator. Liebherr accepts no warranty or liability for damage of any kind in the event of breakdowns or damage to Liebherr machines caused by the use of third-party products.

- In addition, Liebherr will also reject any warranty claims for damage caused by improper use, insufficient maintenance, or failure to observe safety instructions.

Modifications, conditions, copyright

- We reserve the right to make changes without notice as a result of technological development.

- The information and illustrations in this manual may not be reproduced, distributed, or used for commercial purposes. All rights under copyright law are expressly reserved.

- The warranty and liability terms contained in Liebherr’s general conditions of trade are not affected by the information in the manual.

TABLE OF CONTENTS:

Liebherr L 538 1268 Wheel Loader Operator’s Manual SN 34983 – PDF DOWNLOAD

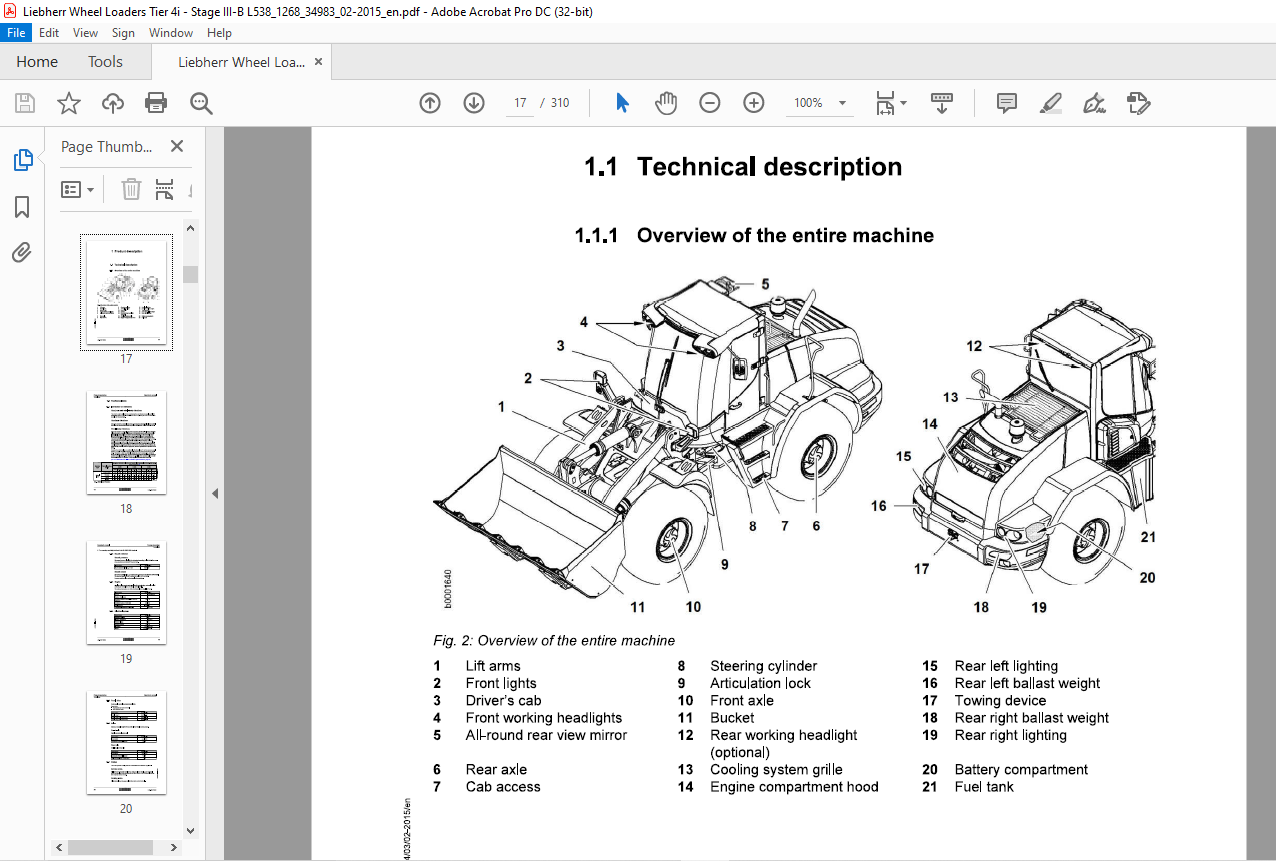

1.1 Technical description 17

1.1.1 Overview of the entire machine 17

1.2 Technical data 18

1.2.1 Information on vibrations 18

1.2.2 Sound emission 19

1.2.3 Engine 19

1.2.4 Electrical system 19

1.2.5 Travel drive 20

1.2.6 Axles 20

1.2.7 Brakes 20

1.2.8 Steering 21

1.2.9 Working hydraulics 21

1.2.10 Liftarms 21

1.2.11 Driver’s cab 22

1.2.12 Heating, air conditioning 22

1.2.13 Air conditioning system 22

1.2.14 Refuelling pump 23

1.2.15 Towing device 23

1.2.16 Ballast 23

1.2.17 Tyres 24

1.2.18 Snow chains or guard chains 27

1.2.19 Tyres with foam 27

1.2.20 Complete machine with loading bucket (Z kinematics) 27

1.2.21 Complete machine with loading bucket (parallel kinematics) 29

1.2.22 Attachment: Light material bucket 31

1.2.23 Attachment: High dump bucket 32

1.2.24 Attachment: Forklift 34

2.1 How the warnings are marked 37

21.1 Further markings 37

2.1.2 Additional rules and guidelines 38

2.2 Proper use 38

2.3 Signs on the machine 38

2.3.1 Safety decals 38

2.3.2 Information decals 42

23.3 Type plate 49

2.4 Safety instructions 50

2.41 General safety instructions 50

2.42 Instructions on preventing crushing injuries and burns 51

2.4.3 Instructions on preventing fires and explosions 52

2.4.4 Safety instructions for start-up 52

2.4.5 Safety precautions during start-up 52

2.46 Instructions for safe working 53

2.47 Safety instructions for driving on slopes 54

2.48 Parking safely 54

2.49 Transporting the machine safely 55

2.4.10 Towing the machine safely 55

2.4.11 Measures for ensuring safe maintenance 56

2.4.12 Safety instructions for maintenance work on machines with hydro

accumulators 58

2.4.13 Safety instructions for welding work on the machine 58

2.4.14 Instructions for working safely on the attachment 59

2.4.15 Safety instructions for transporting the machine by crane 59

2.4.16 Safe maintenance of hydraulic hoses and hose lines 59

2.417 Roll-over protection structure (ROPS) and falling object protection

structure (FOPS) 60

2.4.18 Attachments and accessories 61

2.4.19 Protection against vibrations 61

2.4.20 See and be seen 62

3 Handling and operation 63

3.1 Control elements 63

3.1.1 Driver’s cab 63

3.1.2 Display 64

3.1.3 Control unit 65

3.1.4 Switches/buttons 66

3.1.5 Control lever 67

3.2.1 Battery main switch 68

3.2.2 Articulation lock 68

3.2.3 Cab access 70

3.24 Cab windows 71

3.2.5 Emergency exit 73

3.2.6 Fire extinguisher 74

3.2.7 Driver’s seat 75

3.2.8 Safety belt 85

3.2.9 Steering column and steering wheel 86

3.2.10 Control panel 87

3.2.11 Start switch 88

3.2.12 Electronic immobiliser 88

3.2.13 Driver identification 92

3.2.14 Steering column switch 94

3.2.15 Lighting 95

3.2.16 Interior lighting of the driver’s cab 98

3.217 LCD 98

3.2.18 Touch screen display 102

3.2.19 Control lever 122

3.2.20 Controlling a working attachment with an independent hydraulic circuit 125

3.2.21 Heating, ventilation, air conditioning (optional) 137

3.2.22 Rear window heater and mirror heater (optional) 141

3.2.23 Interior and exterior mirrors 141

3.2.24 Sun visor 142

3.2.25 Radio 142

3.2.26 Windscreen wiper and washer system 143

3.2.27 Liebherr automatic central lubrication system 144

3.2.28 Back-up alarm 148

3.2.29 Reversible fan drive 151

3.2.30 Working basket 151

3.2.31 LIDAT 152

3.3.1 Daily start-up 153

3.3.10 Filling the tank using the filling pump 180

3.3.11 Forklift 181

3.3.12 2-in-1 steering 183

3.4.1 Picking up material 185

3.56.1 Removing the working attachment from the quick-change device 194

3.6.1 Transporting the machine 200

3.7.1 Lowering the lift arms if the engine fails 204

Malfunctions 215

4.1 Servicecodes 215

4.1.1 Service code indicator in the display 215

4.2 Problems – Cause – Remedy 220

42.1 Warning symbols 220

4.2.2 Troubleshooting the Liebherr automatic central lubrication system 221

4.3 Problem remedy 222

4.3.1 Replacing fuses 222

Maintenance 227

5.1 Maintenance and inspection schedule 227

5.2 Filling quantities and lubrication chart 232

52.1 Recommended lubricants 232

5.2.2 Recommended operating fluids 233

5.2.3 Lubrication chart 233

5.3 Lubricants and fuels 236

5.3.1 General information on changing lubricants and fuels 236

harmless hydraulic fluids 236

5.3.3 Diesel fuels 237

5.3.4 Lubricating oils for diesel engines 238

5.3.5 Coolants for diesel engines 240

5.3.6 Hydraulic oil 242

5.3.7 Lubricating oils for transmissions 245

5.3.8 Lubricating oils for axles 246

5.3.9 Lubrication grease and other lubricants 247

5.4 Safety precautions 249

5.5 Preparatory tasks for maintenance 250

5.5.1 Maintenance positions 250

5.5.2 Opening the service accesses 251

5.5.3 Turning off the battery main switch 253

5.6 Overall machine 254

56.1 Checking the machine for external damage 254

5.6.2 Removing loose parts, dirt, ice and snow from the machine 254

5.6.3 Cleaning the machine 254

5.6.4 Shutting down the machine for a lengthy period 256

5.6.5 Deactivating the machine 256

5.6.7 Making sure the bolted connections are tight 257

5.6.8 Corrosion protection on machines that work with salt and artificial

5.6.9 Oil analyses 257

Drive group 264

5.7.1 Checking the engine oil level 264

5.7.2 Draining off condensate and sediment from the fuel tank 264

5.7.3 Draining off condensate from the fuel pre-filter 265

5.7.4 Changing the fuel pre-filter 266

5.7.5 Changing the fuel fine filter 268

5.7.6 Bleeding the fuel system 269

5.7.7 Cleaning the air filter service cover and dust discharge valve 270

5.7.8 Cleaning or changing the main filter element 271

5.7.9 Changing the air filter safety element 274

Cooling system 276

5.8.1 Checking the coolant level 276

5.8.2 Checking the coolant antifreeze and corrosion inhibitor concentration 277

5.8.3 Cleaning the cooling system 281

Working hydraulics 283

5.9.1 Checking the oil level in the hydraulic tank 283

Steering system 285

5.10.1 Testing the steering 285

5.10.2 Lubricating the bearing points on the steering cylinders 285

Brake system 287

5.11.1 Testing the service brake and parking brake 287

Electrical system 289

5.12.1 Checking the lights 289

Axles and cardan shafts 290

5.13.1 Checking the tyre pressure 290

5.13.2 Checking the wheel tightness (once after 50, 100 and 250 h) 291

Steel components of the basic machine 292

5.14.1 Lubricating the articulated bearing and the rear oscillating bedding 292

5.14.2 Covering – lubricating locks and hinges 292

Working attachment 294

5.15.2 Checking the lift arm bearing bushings 295

5.15.3 Lubricating and testing the quick-change device 296

5.16 Cab, heating and air conditioning 298

5.16.1 Cleaning the fresh and recirculated air filters 298

5.16.2 Changing the fresh and recirculated air filters 299

5.16.3 Checking the condition and function of the safety belt 300

5.16.4 Checking and topping up the windscreen washer reservoir 300

5.16.5 Checking the seals on the driver’s cab 301

5.17 Lubrication system 302

5.17.1 Checking the lubrication system grease reservoir level 302

5.17.2 Checking the pipes, hoses and lubrication points of the lubrication

system 302

5.17.3 Checking whether metered quantities are adequate at the bearing

points (grease collars) of the lubrication system 303

Index 305

IMAGES PREVIEW OF THE MANUAL:

VIDEO PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the SAME manual used by the dealers to troubleshoot any faults in your vehicle. This can be yours in 2 minutes after the payment is made.

- Contact us at [email protected] should you have any queries before your purchase or that you need any other service / repair / parts operators manual.

S.V