Case IH Tractor Precision Hoe 800 Service Manual

FILE DETAILS:

Case IH Tractor Precision Hoe 800 Service Manual_87492443

Size : 7.22 MB

Format : PDF

Language : English

Number of Pages : 171 pages

Brand: Case IH

Type of machine: Tractor

Type of document: Service Manual

Model: Precision Hoe 800

Part Number: 87492443

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Case IH Tractor Precision Hoe 800 Service Manual_87492443

- CHECK with local authorities regarding transport on public roads. Obey all applicable laws and regulations. ONLY TOW at a safe speed [32 km/hr (20 mph)]. Use caution when turning corners or meeting traffic. BE SURE safety lighting is plugged in and that the red taillight(s), amber flashers, and amber signal lights are all working properly.

- ALWAYS be certain that no one is behind or near the drill before moving it. BE SURE all safety transport locks are in place before transporting the drill. BE SURE the reflector decals are clearly visible from all sides of the drill and the ‘Slow Moving Vehicle’ sign is at the rear of the drill in clear view of overtaking traffic.

- BE SURE the tractor weight is equal to or greater than the total weight of the air cart and drill. BE SURE all the wheel bolts are torqued to proper specifications before transporting the drill. WATCH for power poles and overhead power lines.

- ALWAYS lock the tractor drawbar when transporting the drill. ALWAYS park the drill on level ground and block the wheels before unhooking from the towing vehicle. NEVER subject the drill to steep side grades while in transport position. ALWAYS use the hitch jack supplied with the drill when unhooking from the tractor. NEVER brake or decelerate during cornering. ALWAYS enter corners slowly.

- SLOW the machine to turning speed before entering a corner. DO NOT decelerate while executing the turn. SAFETY DECALS KEEP SAFETY DECALS CLEAN. Wipe clean when necessary. CHECK that the safety decals are not obstructed by the openers. If the decals are covered up, replace in a location that is clear to view.

- REPLACE missing or unreadable decals. New decals are available from your dealer. To replace decals: 1. Remove the old decal. Clean the area where the new decal will be affixed. 2. Remove the decal backing. Carefully affix the decal to the drill. 3. Work the air bubbles out from under the decal. Use a clean piece of paper or the decal backing itself.

TABLE OF CONTENTS:

Case IH Tractor Precision Hoe 800 Service Manual_87492443

1 – SAFETY 1-1

Safety

Decal Locations

Reflector Decals, Slow Moving Vehicle Sign and

Transport Lighting

2 – MECHANICAL SERVICE 2-1

General Service Information

Specifications

Locking Openers / Subbar for Service

Replacing the Serial / PIN Plate

Grease Locations and General Maintenance

Storage

Welding Procedures

Precision Disk 30 Frame Brace Kit

Fold Linkages

Wheel Bolt Torque

Hub / Spindles / Wheels

3 – HYDRAULIC SYSTEM SERVICE 3-1

Hydraulics

Hydraulic Cylinder Seal Replacement

Hydraulic Cylinder Components

Wing Lift Hydraulic Schematics

Subbar Hydraulics

4 – ELECTRICAL SYSTEM SERVICE 4-1

Electrical System Service

Clutches and Work Switch

Connector Service Kit

5 – OPENER SERVICE 5-1

Troubleshooting Tables

Adjustments

Opener Service

6 – AIR SYSTEM SERVICE 6-1

Troubleshooting Table

Single Rank Operation

Setting the Fan Speed – Concord Air Systems

Hoses

Theory of Operation

To Determine Adequate Carrying Velocities

Air System Components – Concord Air System

Air System Components – ADX Air System

7 – END MARKER SERVICE 7-1

End markers

Precision Disk 30 End marker

Precision Disk 30 End marker Adjustments

Precision Disk 40 End marker

Precision Disk 40 End marker Ajdustments

End marker Service

INDEX

INDEX DETAILS:

Case IH Tractor Precision Hoe 800 Service Manual_87492443

ADX Air System6-17

Header Assemblies 6-17

Air System6-9

Balancing the Air Flow6-9

Theory of Operation 6-9

Bogie Hub and Spindle 2-27

Bolt Torque 2-4

Caster Assembly2-27

Precision Disk 302-28

Precision Disk 40 2-30, 2-32

Center Section

Precision Disk 302-18

Precision Disk 402-23

Concord Air Systems 6-12

Front Tow Primary Manifold Stand 6-12

Pivot Assembly Manifold Stands6-14

Primary Manifold 6-15

Rear Tow Primary Manifold Stands6-13

Secondary Manifold6-16

Setting the Fan Speed6-7

Connector Service 4-10

Contact Replacement 4-10

Cylinder Components 3-12

Precision Disk 30 Subbar 3-12

Precision Disk 30 Wing Lift 3-14

Precision Disk 40 Subbar 3-13

Precision Disk 40 Wing Lift 3-16

Cylinder Seal Replacement 3-3

Decal Locations1-11

Precision Disk 30 Safety Decal Locations 1-11

Precision Disk 40 Safety Decal Locations 1-12

Dimensions 2-6

Down Pressure 5-5

Spring Position 5-6

Endmarkers 7-3

Bearing Replacement 7-16

Safety 7-3

Service 7-16

Frame Brace Kit2-13

Precision Disk 302-14

General Maintenance2-8

Grease Locations2-8

Hoses6-8

Hydraulic Schematics 3-19

Precision Disk 30 Subbar, 2nd S/N Range 3-24

Precision Disk 30 Subbar, 1st S/N Range 3-26

Precision Disk 30 Wing Lift, 2nd S/N Range 3-19

Precision Disk 30 Wing Lift, 1st S/N Range 3-20

Precision Disk 40 Subbar 3-30

Precision Disk 40 Wing Lift 3-22

Locking Openers / Subbar for Service 2-6

Subbar Cylinder Lock2-6

Open Hose Method 6-10

Openers

Down Pressure 5-5

Gauge Wheel5-8

Scraper 5-7

Seed Firming Wheel5-10

Seed Retention Tab5-10

Opener Service 5-11

Gauge Wheel Assembly5-11

Main Cast Arm Bushings5-17

Packer Wheel Assembly5-13

Repair the Seed Tube 5-16

Scraper Assembly 5-15

Seed Firming Wheel5-14

INDEX

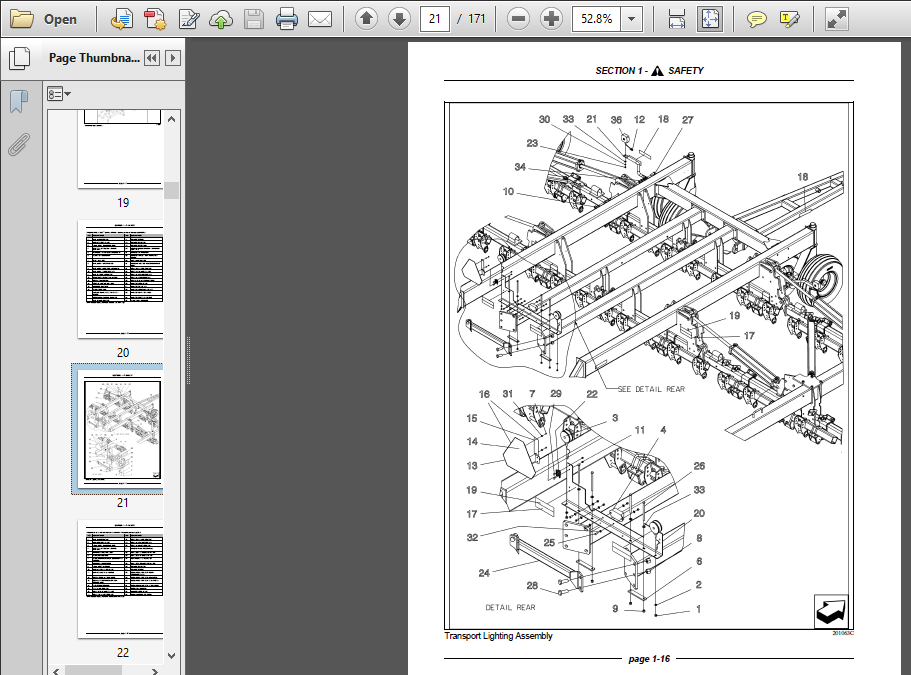

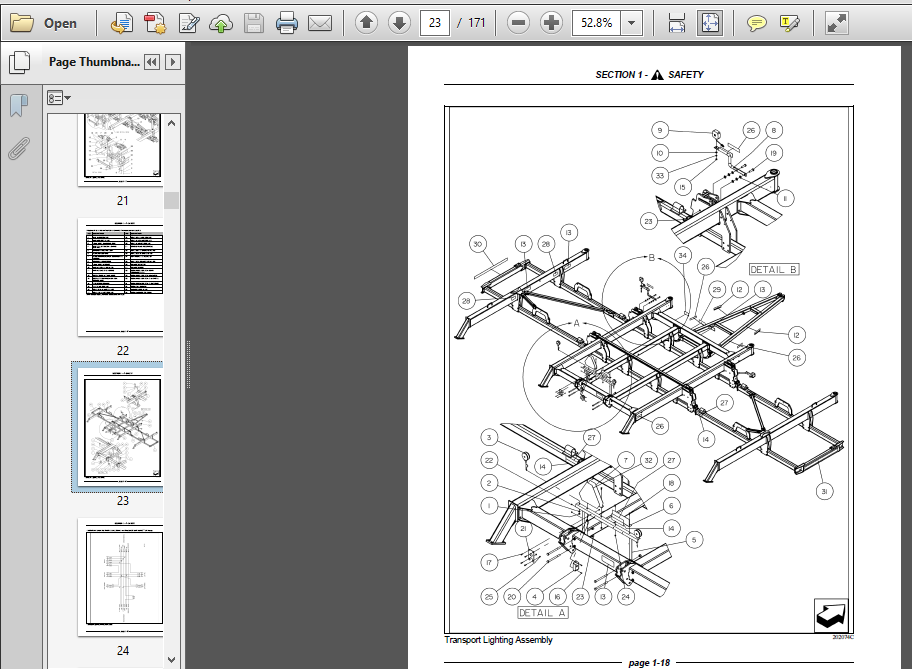

Reflector Decals, Slow Moving Vehicle Sign and

Transport Lighting1-13

Precision Disk 30 1st Serial Range 1-13

Precision Disk 30 2nd Serial Range 1-14

Precision Disk 401-16

Transport Lighting Wiring Schematic1-18

Remote Clutch4-4

Remote Work Switch4-5

Repacking Wheel Bearings 2-27

Repair Part Identificationi

Precision Disk 30i

Precision Disk 40 ii

Replacing Serial/PIN Plate 2-7

Safety 1-3

Air and Air Hoses 1-8

Electrical 1-9

General Safety Practices 1-4

Hydraulics and Hydraulic Leaks 1-8

Safety Decals1-10

Safety During Operation 1-5

Safety During Transport 1-10

Servicing Safety Precautions 1-4

Shields1-9

Tires 1-9

Precision Disk 30 Endmarker7-4

Adjustments 7-7

Hydraulics 7-6

Offset Pin at Knuckle Pivot 7-7

Precision Disk 40 Endmarker 7-10

Adjusting Disc Angle7-14

Bias Spring 7-15

Breakaway Adjustment 7-14

Hydraulics7-12

Single Rank Operation6-6

ADX Air Delivery System 6-6

Concord Air Delivery 6-6

Spindle Specifications 2-27

Storage 2-12

Torque Values for Tie Rods 3-9

Troubleshooting Tables 5-3

Welding 2-13

Wheel Bolt Torque 2-26

Wing Frame2-22

Precision Disk 302-22

Precision Disk 402-24

Wing Lift Ball Valve 3-18

PLEASE NOTE:

- This is the SAME MANUAL used by the dealerships to diagnose your vehicle

- No waiting for couriers / posts as this is a PDF manual and you can download it within 2 minutes time once you make the payment.

- Your payment is all safe and the delivery of the manual is INSTANT – You will be taken to the DOWNLOAD PAGE.

- So have no hesitations whatsoever and write to us about any queries you may have : heydownloadss @gmail.com