Case IH Tractor Magnum 260,290,315,340 Operator’s Manual

FILE DETAILS:

LANGUAGE:ENGLISH

PAGES:452

DOWNLOADABLE:YES

FILE TYPE:PDF

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

- This Manual has been prepared to assist you in the correct procedure for running-in, driving and operating and for the maintenance of your new machine. Read this manual carefully. Your machine is designed to be used in normal and customary agricultural applications.

- If you require technical support for your machine at any time, do not hesitate in contacting your CASE IH dealer. They have company trained personnel, genuine parts and the necessary equipment to carry out all your service requirements. The specification are provided for your information and guidance.

- For further information concerning your tractor and equipment, consult your CASE IH dealer. All data given in this book is subject to production variations. Dimensions and weights are approximate. The illustrations do not necessarily show tractors in standard condition or imply that these features are available in all countries.

- For exact information about any particular tractor, please consult your CASE IH dealer. Your tractor has been designed and built to give maximum performance, economy and ease of operation under a wide variety of operating conditions. Prior to delivery, the tractor was carefully inspected, both at the factory and by your CASE IH dealer to ensure that it reaches you in optimum condition.

- To maintain this condition and ensure trouble-free operation, it is important that the routine services, as specified on page 7-11 of this Manual, are carried out at the recommended intervals.

TABLE OF CONTENTS:

Case IH Tractor Magnum 260,290,315,340 Operator’s Manual

1 GENERAL INFORMATION

NOTE TO THE OWNER 1-1

Product identification1-3

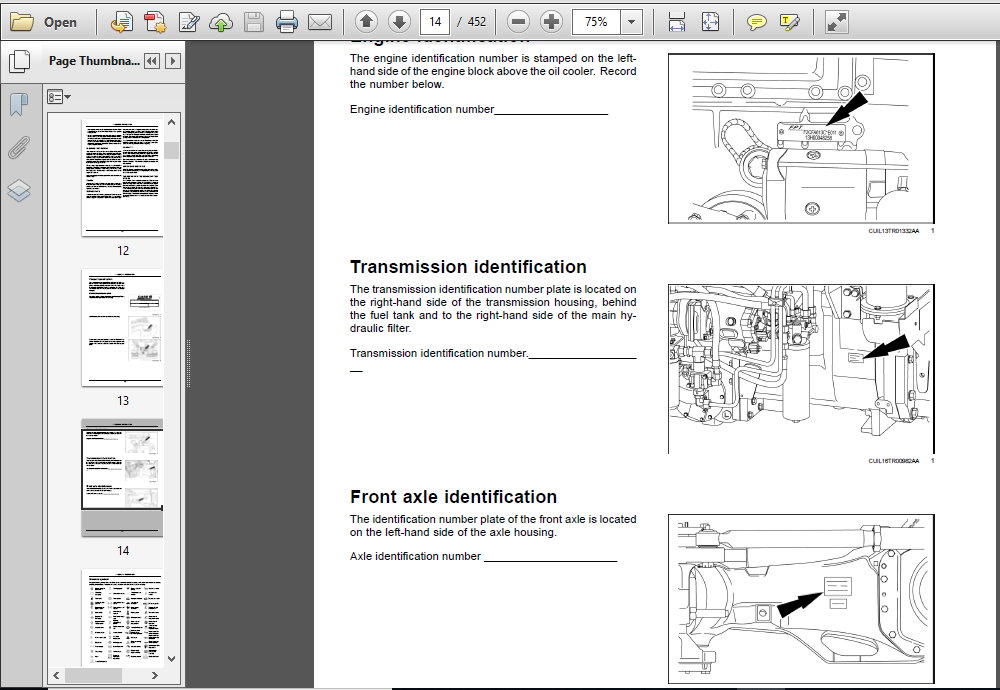

Engine identification 1-4

Transmission identification1-4

Front axle identification 1-4

Universal symbols1-5

2 SAFETY INFORMATION

Safety rules 2-1

Roll Over Protection Structure (ROPS) 2-2

Emergency hammer 2-3

Safety Decals 2-4

Wheel chocks2-10

Noise levels 2-11

Before operating the machine 2-12

Driving the vehicle 2-12

Operating the machine2-13

Power Take-Off (PTO) operation 2-15

Servicing safety precautions2-15

Operating the external controls2-17

Fire or explosion prevention 2-17

Diesel fuel 2-18

Personal safety offered by the machine2-19

Intended use statement 2-22

Ecology and the environment 2-23

3 CONTROLS AND INSTRUMENTS

ACCESS TO OPERATOR’S PLATFORM

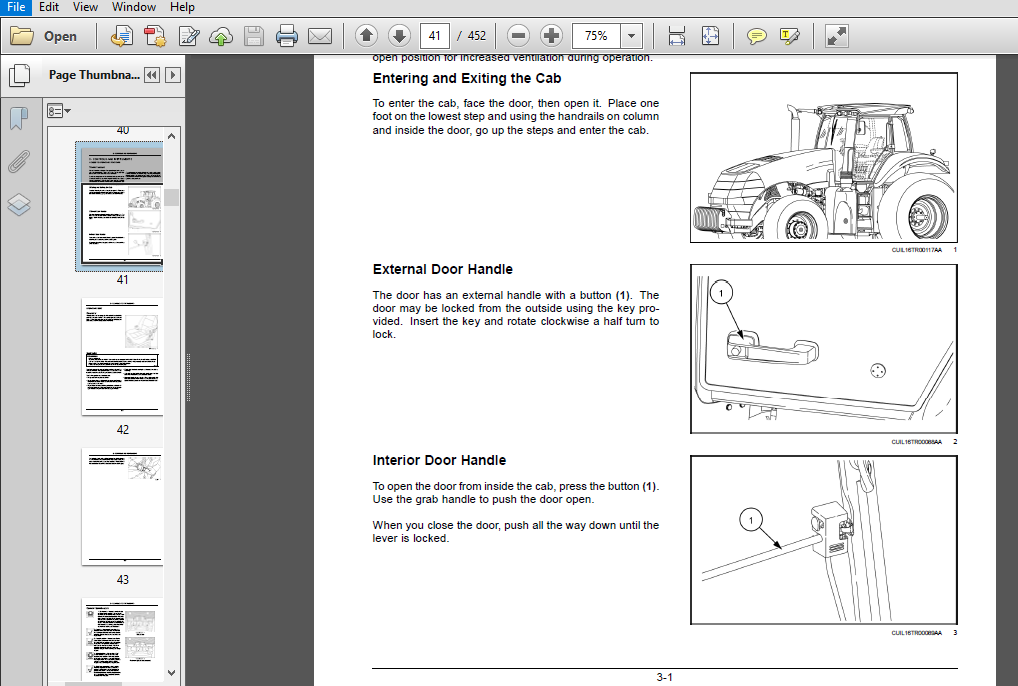

Tractor access3-1

OPERATOR’S SEAT

Overview 3-2

Seat belts 3-2

Control identification 3-4

INSTRUCTOR’S SEAT

Instructor’s seat (when fitted) 3-7

FORWARD CONTROLS

Steering column 3-8

Front console3-11

Pedal controls 3-13

RIGHT-HAND SIDE CONTROLS

Armrest console3-15

Multi-function handle 3-16

Control panel3-20

Remote valve controls 3-28

Armrest compartment3-29

Adjusting the armrest console 3-31

REARWARD CONTROLS

Right-hand console3-32

Automatic temperature control system 3-35

Ventilation3-36

OVERHEAD CONTROLS

Interior lamps3-38

EXTERIOR CONTROLS

Rear remote hitch switch – When available 3-38

INSTRUMENT CLUSTER

Overview 3-39

Gauges3-39

Status and warning icons 3-40

Upper display3-43

Lower display3-45

Keypad3-46

Setup menu 3-48

Rear tire radius chart 3-54

Adjust menu 3-55

Performance instrumentation 3-62

4 OPERATING INSTRUCTIONS

COMMISSIONING THE UNIT

Fueling the machine4-1

Before starting the engine4-2

STARTING THE UNIT

Normal engine starting4-5

Cold temperature operation 4-8

STOPPING THE UNIT

Stopping the engine 4-10

MOVING THE UNIT

Powershift transmission – Safety rules 4-12

Powershift transmission – Operating4-13

Throttle control – Operating 4-14

Powershift transmission external controls – Control identification 4-15

Instrument cluster – Localization overview4-18

Driving the vehicle 4-19

Start off gear – Standard (SOG) 4-24

Operating speeds 4-27

Automatic productivity management (APM) 4-30

Auxiliary Front Wheel Drive4-35

Differential lock system 4-39

Ride control 4-42

Constant engine speed 4-44

Headland management system 4-46

5 TRANSPORT OPERATIONS

PREPARING FOR ROAD TRANSPORT

Safe transport speed 5-1

Safety chain 5-1

SHIPPING TRANSPORT

Securing the tractor for shipping 5-2

RECOVERY TRANSPORT

Safety rules5-4

Towing the tractor 5-5

6 WORKING OPERATIONS

GENERAL INFORMATION

Implement connections6-1

Two-speed rear Power Take-Off (PTO)

Safety rules 6-2

Connecting the PTO 6-5

Rear PTO operation 6-6

Auto PTO operation 6-10

REAR HITCH

Identification6-13

Link adjustment 6-13

Hitch high clearance adjustment6-17

Sway limiter adjustment6-19

Lower link block adjustment 6-20

Mechanical float adjustment 6-21

Hitch quick coupler – Category III/IIIN 6-22

Hitch quick coupler – Category IVN6-26

Hitch operation – Operation modes6-30

Hitch remote switch operation6-34

Position control operation 6-35

Load control operation 6-37

Operation – Slip control6-38

Hitch set point 6-39

DRAWBARS AND TOWING ATTACHMENTS

Drawbars and towing hitches – Safety rules 6-41

Drawbar capacity/position 6-42

Adjusting the drawbar 6-44

AUXILIARY POWER CONNECTIONS

Auxiliary power and lighting 6-46

Cab power connections6-46

HYDRAULIC REMOTE CONTROL VALVES

Valve couplers and connections 6-48

Motor return circuit 6-51

Power beyond hydraulic valve (when fitted)6-52

Hydraulic transport lock6-53

Operating the controls 6-54

Remote valve display screens 6-58

Remote hydraulic auto mode 6-61

Auto depth control6-63

Tractor ballasting

Tire care – Wheels 6-65

Tires – Calibration and assembly safety 6-68

Tires – Parts of the tire 6-69

Tire types – For the application 6-69

Tires – General features 6-70

Tires – Compatibility of front x rear tires 6-73

Tractor ballasting 6-75

Ballasting6-79

Tires Compatibility table 6-82

Liquid ballast – Capacity table 6-85

Tires – Recommendations for calibration6-98

Assembly – Tires6-100

Tires – Calibration 6-101

Tire pressures and permissible loads6-102

Weights, cast metal and liquid 6-105

Front axle identification6-107

MECHANICAL FRONT DRIVE (MFD) AXLES

Steering and oscillation stops 6-108

Fender – Configure 475 axle 6-110

Fender – Configure 6-115

Front wheel tread settings6-124

Front wheels – Toe in adjust 6-129

REAR AXLE

Rear wheel installation6-130

Rear wheel tread settings6-133

7 MAINTENANCE

GENERAL INFORMATION

Introduction7-1

Fuel handling precautions7-2

Diesel fuel 7-4

Specifications – Biodiesel fuel 7-5

Organic Acid Technology (OAT) coolant7-7

Opening the hood 7-8

Closing the hood7-8

Tractor jacking points 7-9

MAINTENANCE CHART

Maintenance chart7-11

At warning message display

Engine air filter – Outer element 7-13

Drain the fuel system water separator 7-16

Transmission oil filter sensor 7-17

Engine crankcase breather filter 7-20

First 10 hours

Wheel nuts tightening torque 7-21

First 50 hours

First 50 Hour Service 7-21

First 300 hours

Accumulators7-22

First 600 hours

Accumulators7-23

Every 10 hours or daily

Engine oil level 7-24

Transmission oil level7-25

Engine coolant level 7-26

Windshield wiper fluid reservoir 7-26

Pneumatic brake reservoir 7-26

Wheels – Check7-27

Every 50 hours or weekly

Cab air filters7-28

Cab recirculation air filter7-30

Lubrication points 7-30

Pre-fuel filter 7-36

Cleaning the radiators7-37

Every 300 hours

Engine oil and filter7-39

Replace fuel pre-filter7-41

Primary fuel filter 7-44

Cab air filters activated charcoal 7-47

Engine air intake hoses 7-48

Check the coolant level 7-49

Weight bolt torque 7-49

Front axle hub oil (4WD) – oil level 50 axle 7-50

Front axle hub oil (4WD) – oil level 475 axle7-50

Front axle (4WD) oil level 7-50

Transmission oil pressure 7-51

Grease Power Take-Off (PTO) shaft7-51

Every 600 hours

Engine oil and filter7-52

Engine coolant hoses and clamps 7-54

Fuel injection system7-56

Front axle hub oil – Change fluid Class 475 axle 7-56

Front axle hub oil – Change fluid Class 50 axle7-57

Wheel nuts tightening torque 7-57

Fan belt7-58

Every 1200 hours or annually

Engine air filter – Outer element 7-59

Engine air filter – Inner element 7-59

Engine air pre filter7-61

Front axle differential oil 7-63

Drive shaft – Lubricate the drive shaft 7-65

Pneumatic brake system dryer7-65

Engine valves adjust 7-66

Accumulators7-66

Cab air filter 7-67

Cab recirculation air filter7-68

Every 1500 hours

Transmission oil7-69

Strainers – Transmission oil 7-69

Engine crankcase breather filter 7-71

Every 3000 hours

Fuel injectors7-74

Shock absorber – Engine vibration 7-74

Every 4000 hours or every 4 years

Engine coolant replacement 7-74

As required

Fan belt7-76

Fuses and Relays 7-78

Vehicle fire prevention7-84

Cab suspension, if equipped 7-84

Remote valve collection bottle7-85

Cab fabric and carpet7-85

Seat belt 7-86

Fuel tank – Drain fluid7-86

STORAGE

Storing the machine 7-87

Preparation for use after storage7-88

ELECTRICAL SYSTEM

Battery removal and installation 7-89

Auxiliary battery connections 7-91

Headlight – Replace 7-92

Fender tail light and warning light7-95

Roof warning light 7-97

High intensity work light 7-98

Cab interior light – Replace7-100

8 TROUBLESHOOTING

ALARM(S)

Display warnings overview 8-1

Display warnings – Level 1 8-2

Display warnings – Level 2 8-3

Display warnings – Level 3 8-6

Display warnings – Level 4 8-6

SYMPTOM(S)

Engine symptoms 8-8

Transmission symptoms8-9

Hydraulic symptoms 8-10

Hitch symptoms 8-10

Brake symptoms 8-10

Cab environment symptoms 8-11

Electrical power system symptoms8-11

9 SPECIFICATIONS

Fluids and lubricants9-1

Engine specifications9-3

Power train specifications 9-4

Hydraulic system specifications 9-4

Remote control valve specifications9-4

Brake specifications 9-5

Power Take-Off (PTO) specifications 9-5

Specifications – Front axles 9-5

Specifications steering 9-5

Specifications Rear hitch system 9-5

Electrical system specifications 9-6

Vehicle dimensions and shipping weight 9-7

Weight distribution9-8

Ballasting solid9-8

Maximum operating weight 9-10

10 ACCESSORIES

Farming system displays 10-1

Trailer brake connections10-2

General accessories 10-3

PLEASE NOTE:

- This is the SAME manual used by the dealers to troubleshoot any faults in your vehicle. This can be yours in 2 minutes after the payment is made.

- Contact us at [email protected] should you have any queries before your purchase or that you need any other service / repair / parts operators manual.