Case IH Tractor FARMALL 95U,105U,115U Operator’s Manual

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

This manual contains information concerning the adjustment and maintenance of your new equipment. You have purchased a dependable machine, but only by proper care and operation can you expect to receive the performance and long service built into this equipment. Please have all operators read this manual carefully and keep it available for ready reference. The CASE IH dealer will provide instructions on the general operation of new equipment.

- The dealer’s staff, assigned to maintenance, is available for any questions related to the operation of the machine. Your CASE IH dealer carries a complete line of genuine CASE IH service parts.

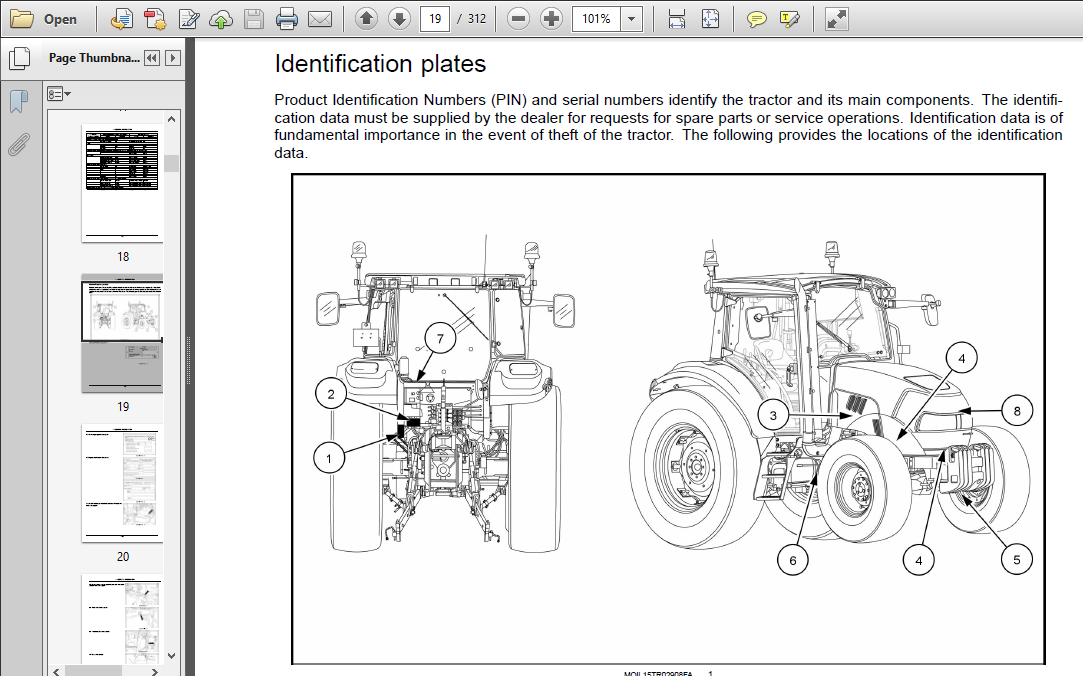

- These parts are manufactured and carefully inspected to insure high quality and accurate fitting of any necessary replacement parts. Be prepared to give your dealer the model and product identification number of your new equipment when ordering parts.

- Locate these numbers now and record them below. Refer to the ‘General Information’ section of this manual for the location of the model code and product identification numbers of your machine.

TABLE OF CONTENTS:

Case IH Tractor FARMALL 95U,105U,115U Operator’s Manual

1 GENERAL INFORMATION

Note to the Owner1-1

Intended use 1-3

Electro-Magnetic Compatibility (EMC)1-5

Manual scope and required training level1-6

Metric and imperial units abbreviations 1-7

Identification plates 1-9

Approval data plate 1-13

Operator’s manual storage on the machine1-13

Machine orientation1-14

EC Declaration of Conformity 1-15

Exhaust Gas Recirculation (EGR) system 1-17

2 SAFETY INFORMATION

Safety rules and signal word definitions 2-1

Safety rules – General information 2-2

Safety rules – Wheels and tires 2-2

Safety rules – Explosions and fires2-3

Safety rules – Fire extinguisher 2-3

Safety rules – Battery 2-4

Safety rules – Passenger seat 2-4

Safety rules – Operator presence system 2-5

Safety rules – Power Take-Off (PTO) 2-5

Safety rules – Reflectors and warning lights2-5

Safety rules – Seat belts 2-5

Safety rules – Operator protective structure2-5

Safety rules – HVAC system 2-7

Safety rules – Personal Protective Equipment (PPE)2-7

Safety rules – “Do not use” sign 2-8

Safety rules – Hazardous chemicals 2-8

Safety rules – Near utilities2-8

Safety rules – In the event of electrical storms 2-8

Safety rules – Mounting and dismounting the machine 2-9

Safety rules – Lifting and overhead loads2-9

Safety rules – Front end loader 2-9

Ecology and the environment 2-11

Commission directive 2010/52/EU2-12

Noise level2-19

Vibration levels 2-20

Machine stability2-21

Towing the tractor for recovery 2-24

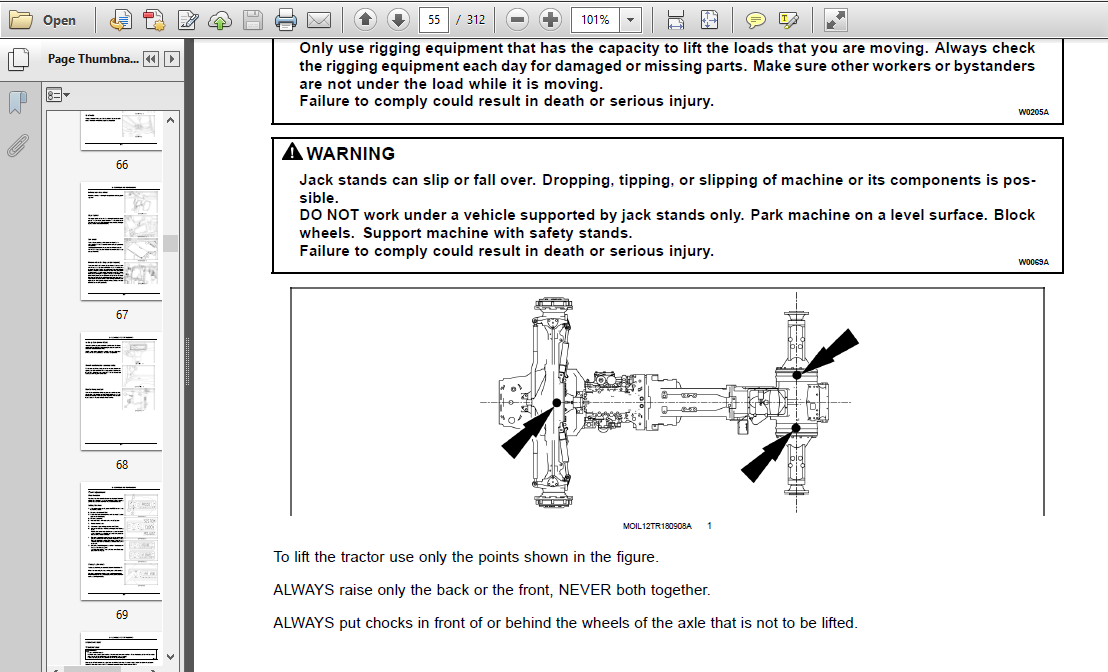

Tractor jacking points 2-25

Burn prevention 2-26

Emergency Exit 2-27

Wheel chock 2-28

Safety signs 2-29

3 CONTROLS AND INSTRUMENTS

ACCESS TO OPERATOR’S PLATFORM

Getting in and out of the machine 3-1

Getting to know the internal parts of the cab 3-2

Clock adjustment3-5

OPERATOR’S SEAT

Standard seat3-6

Air seat “DELUXE” model3-7

Air seat “PREMIUM” model 3-9

Seat belt 3-12

Passenger seat 3-13

FORWARD CONTROLS

Instrument panel 3-14

Front controls3-19

LEFT-HAND SIDE CONTROLS

Left side post controls3-22

Hand brake 3-23

RIGHT-HAND SIDE CONTROLS

Right side post controls 3-24

Right-hand console3-25

Heating, ventilation or air-conditioning control 3-26

EXTERIOR CONTROLS

Exterior controls3-28

DISPLAY SETTINGS

Programmable display 3-29

Ground speed calibration 3-30

Display warnings overview 3-33

4 OPERATING INSTRUCTIONS

COMMISSIONING THE UNIT

Basic operating safety rules 4-1

Filling the fuel tank 4-2

STARTING THE UNIT

Starting the engine 4-3

Engine coolant heater 4-4

STOPPING THE UNIT

Stopping the engine4-5

Battery isolator control switch 4-5

MOVING THE UNIT

Machine movement start-up4-6

Operating in cold temperatures4-7

Low idle speed management4-8

5 TRANSPORT OPERATIONS

ROAD TRANSPORT

Transporting the machine5-1

RECOVERY TRANSPORT

Recovery and towing 5-2

Towing the tractor 5-3

6 WORKING OPERATIONS

GENERAL INFORMATION

Four wheel drive6-1

Differential lock 6-2

Transmission

Transmission operation 6-3

Remote control valves

General safety rules 6-7

Front remote control valve couplers 6-8

Rear remote control valve(s) 6-9

Joystick for control valves

Mechanical Joystick 6-13

Electronic Joystick 6-14

Rear Power Take-Off (PTO)

Safety rules 6-17

Changing the Power Take-Off (PTO) shaft 6-18

Attaching Power-Take Off (PTO) driven equipment 6-19

Indipendent Power Take-Off 6-20

Ground speed Power Take-Off 6-22

Power take-off speeds 6-23

Exterior controls 6-24

Front Power Take-Off (PTO)

Safety rules 6-26

Operating Instructions 6-27

Rear hydraulic lift

Safety precautions 6-29

Hydraulic lift with electronic control6-30

Operating Instructions 6-35

Front hydraulic lift

Front hitch – Operating 6-40

Rear three-point hitch

Three-point linkage 6-41

Quick hitch 6-43

Three-point hitch front

Three-point hitch adjustments6-45

Hitching tools for quick coupling6-47

Towbar

Safety rules 6-48

Swinging drawbar6-49

Towing hook

Safety rules 6-50

Rear tow hitch 6-51

Trailer braking systems

Hydraulic trailer brakes (Universal type) 6-53

Hydraulic trailer brakes (Italian type) (Italian type)6-54

Trailer brake connections 6-56

Air-operated trailer brakes6-57

Tires and wheels

Wheels and tires 6-60

Tire dimensions 6-64

Tread and fender settings – standard MFD axles

Track adjustment 6-66

Track adjustment 6-67

Disc-to-rim coupling for front 4WD tires 6-68

Front fixed fenders 4WD 6-69

Adjustment of the steering angles 6-70

Tire combinations and tread positions6-71

Ballasting

Safety rules 6-74

Metal ballast6-75

Liquid Ballast 6-76

Power sockets

Power sockets 6-80

Diagnostic socket6-81

7 MAINTENANCE

GENERAL INFORMATION

General safety before you service7-1

Introduction7-3

Body maintenance 7-4

General specification – Diesel fuel7-6

General specification – Biodiesel fuels 7-6

Organic Acid Technology (OAT) coolant7-9

Consumables7-11

Capacities7-12

Recommended engine oil for operating temperature ranges 7-13

Opening the hood 7-14

MAINTENANCE CHART

Maintenance chart7-15

As required

Engine coolant level – Check 7-17

Windshield washer fluid reservoir – Filling 7-17

Air conditioning – Check 7-17

Hand brake lever – Check 7-18

Remote control valvas oil recovery pan – Check7-18

Radiator – Cleaning7-19

Brake pedals – Check7-19

Wheels – Check7-19

Hydraulic hoses – Check7-20

At warning message display

Engine air filter – Cleaning 7-21

Fuel filters – Drain fluid 7-22

Brake fluid reservoir – Filling 7-23

Engine oil and filter – Replace 7-23

Every 10 hours or daily

Engine oil level – Check 7-24

Air tanks – Drain fluid 7-24

After the first 50 hours of operation

Maintenance – Check 7-26

Maintenance – Replace 7-26

Every 50 hours

Rear three-point hitch – Grease 7-27

Tow hitch – Grease7-27

Front axle system – Grease7-28

Front hitch – Grease 7-28

Every 100 hours

Air-conditioning condenser – Cleaning 7-29

Transmission cooler – Cleaning 7-29

Aftercooler – Cleaning7-30

Cab air filters – Cleaning7-30

Cab air recirculation filter – Cleaning – Recirculation Filters7-31

Alternator drive belt – Check – Alternator belt7-32

Air conditioning compressor belt – Check – Air conditioner belt7-32

Pneumatic trailer brakes compressor belt – Check 7-32

Every 300 hours

Hydraulic oil filter – Replace7-34

Auxiliary services oil filter – Replace7-34

Hydraulic Oil Level – Check7-35

Steering knuckle and king pin – Grease7-36

Front axle oil level – Check 7-37

Final drive – Check7-37

Engine air filter – Cleaning 7-37

Every 600 hours

Engine oil and filter – Replace 7-39

Fuel filters – Replace 7-41

Wheels – Tighten 7-43

Every 1200 hours or annually

Cab air filters – Replace 7-44

Cab air recirculation filter – Replace – Recirculation Filters 7-44

Engine air filter – Replace 7-45

Wheel hub – Grease 7-45

Fuel tank – Drain fluid7-46

Every 1200 hours or two years

Final drive – Change fluid7-47

Front axle oil – Change 7-47

Hydraulic oil – Replace 7-47

Alternator drive belt – Replace – Alternator belt 7-48

Air conditioning compressor belt – Replace – Air conditioner belt 7-48

Pneumatic trailer brakes compressor belt – Replace 7-48

Engine coolant (conventional type coolant) – Change fluid 7-49

Every two years

Receiver/Dryer – Replace 7-51

Every 3600 hours

Diesel Particulate Filters (DPF) – Replace7-52

Every 3600 hours or four years

Engine coolant (OAT type coolant) – Change fluid 7-53

ELECTRICAL SYSTEM

Fuse and relay locations7-55

Light adjustments 7-61

Hood lamp replacement 7-61

STORAGE

Tractor storage7-62

CALIBRATION

Clutch calibration 7-63

8 TROUBLESHOOTING

FAULT CODE RESOLUTION

TROUBLESHOOTING ENGINE 8-1

Electrical system – Troubleshooting 8-3

Hydraulic systems – Troubleshooting8-4

Rear three-point hitch – Troubleshooting 8-5

Hydraulic service brakes – Troubleshooting 8-6

Cab climate control – Troubleshooting 8-7

SYMPTOM(S)

Viewing error codes 8-8

Error code identification 8-9

9 SPECIFICATIONS

Dimensions and weights 9-1

Maximum permitted loads on front and rear axle 9-3

Maximum permitted loads on drawbar 9-4

Maximum permitted loads on towing hitch 9-4

Additional equipment attachment points 9-5

Speed table for 12 x 12 gearbox 9-7

Speed table for 20 x 20 gearbox 9-9

Speed table for 24 x 24 gearbox 9-11

Consumables 9-15

Capacities 9-16

Technical data 9-17

10 ACCESSORIES

Radio 10-1

Front-end loader fixation points 10-13

FILE DETAILS:

Case IH Tractor FARMALL 95U,105U,115U Operator’s Manual

LANGUAGE:ENGLISH

PAGES:312

DOWNLOADABLE:YES

FILE TYPE:PDF

PART NUMBER:47874286

PLEASE NOTE:

- This is the SAME exact manual used by your dealers to fix your vehicle.

- The same can be yours in the next 2-3 mins as you will be directed to the download page immediately after paying for the manual.

- Any queries / doubts regarding your purchase, please feel free to contact [email protected]