Case IH Tractor Drum Overhaul Cotton Picker Service Manual

FILE DETAILS:

Case IH Tractor Drum Overhaul Cotton Picker Service Manual_GSS1077C

Size : 24.7 MB

Format : PDF

Language : English

Number of Pages : 51 pages

Brand: Case IH

Type of machine: Tractor

Type of document: Service Manual

Model: Drum Overhaul Cotton Picker

Part No: GSS1077C

DESCRIPTION:

FOREWORD:

- The instructions and special tools shown in this Blue Ribbon Service Manual are for use by International Harvester Dealers and their factory trained servicemen.

- The specifications as listed in this manual are current as of the printing date. Due to changes and improvements in our products, dealers are periodically issued service bulletins to keep this manual up-to-date. We suggest you refer to the most recent information when performing service work on this equipment.

DESCRIPTION AND PRINCIPLES OF OPERATION:

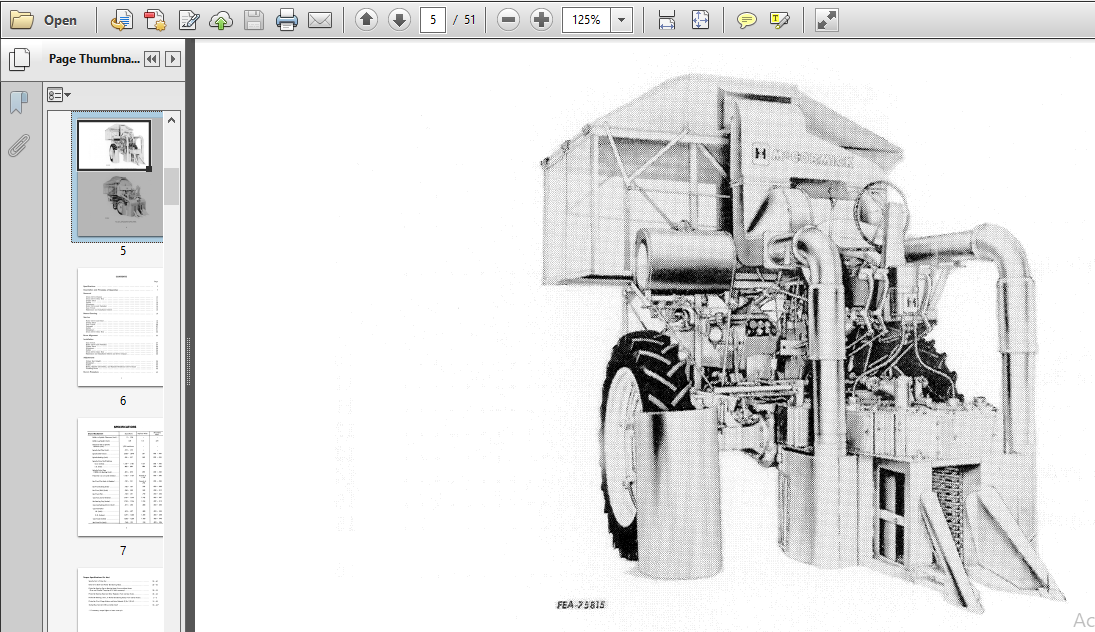

- International Harvester Factory Trained servicemen are best qualified to service I.H. equipment. This manual covers the servicing procedures for the components of Cotton Picker Drums.

- The various points to be covered and procedures outlined in this manual are a guide for complete overhaul. If you are performing emergency field or shop service. you will use only the steps that are applicable to the problem at hand. Review the “Contents” and determine which steps will be required.

- But remember. it is better to do extra work than not to do enough. McCormick one and two row cotton pickers are designed so that. as they move down the row. they pick from both sides of the plants.

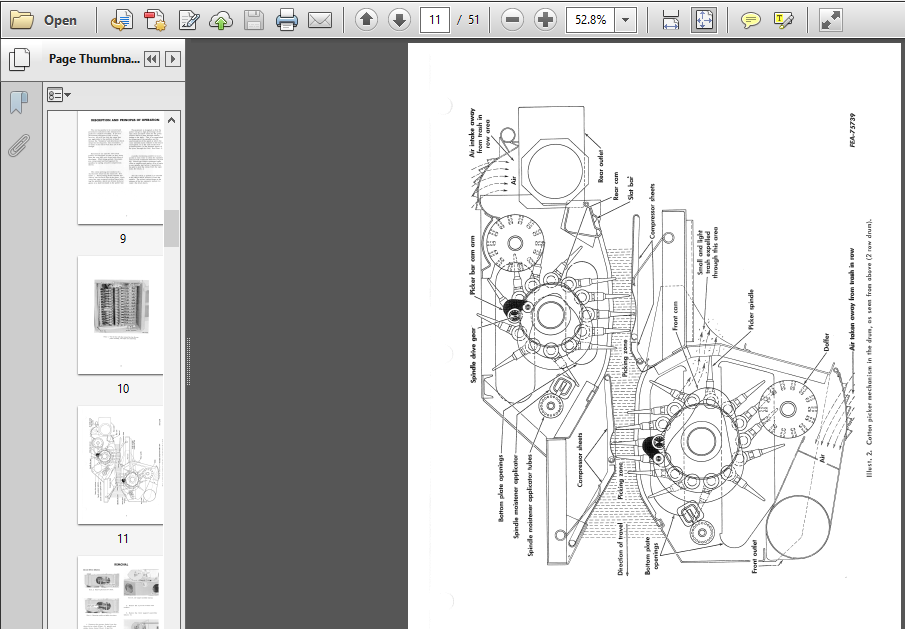

- While being picked, the plants are compressed and held against the spindles by spring actuated compression sheets. The cotton picking unit consists of a sturdy steel drum box for each row. See Illust.

- 1. Each picking drum contains two rotors, one for each side of the plant. Each rotor has cam-actuated vertical bars hold- ing the spindles. which are driven by bevel gears on a shaft enclosed in the picker bar.

- The equipment is designed so that the pickers will get a high percentage of the open cotton and allow room for the green unopened bolls to pass through without damage to the plant.

- This is accomplished by the spacing of the spindles and the synchronization of the speed at which the rotor assembly turns relative to the tractor travel speed. or in the case of the self- propelled picker, to the forward travel of the picker through the field. See Illust.

- 2. A spindle moistening system is incor— porated in each rotor to clean the spindles and to provide maximum efficiency of pick- ing. Finncd type rubber moistener pads clean the spindles and apply a film of water to each spindle just before it penetrates the plant to pick the cotton from the open bolls. See Illust.

- 2. After the cotton is picked it is carried to the doffers which remove it from the spindles. The picked cotton drops at the entrance of the air conveyor system lo— cated at the drum doors.

IMAGES:

VIDEO PREVIEW:

TABLE OF CONTENTS:

Case IH Tractor Drum Overhaul Cotton Picker Service Manual

Specifications

Description and Principles of Operation

Removal

Drum Drtve Cheins

Drum Drich car Box

Pickor Bars

Defier

IIoistener

Rumr Drive and hdesml

smuanarymdrtdjustableldlers

Steam Cleaning

Service

Rotor Driveand Head

Picker-Bare

Pedestal

Doiter

Moistener

Dmm Drive Gear Box

Drum Alignment

Installation

Cam’l‘rack

Rotor Driveand Pedesml

Picker Bers

Moistencr

Dotfcr

Dmm Drive gear Box

Stationary and Adjustable idlersandbrtve Chalns

Adiustments

Plcker Bariicigi’It

Moistener

Rotor, Spindle and Butler, and Spindle Moistcncr Drive Chains

Flushing Drum

PLEASE NOTE:

⦁ This is not a physical manual but a digital manual – meaning no physical copy will be couriered to you. The manual can be yours in the next 2 mins as once you make the payment, you will be directed to the download page IMMEDIATELY.

⦁ This is the same manual used by the dealers inorder to diagnose your vehicle of its faults.

⦁ Require some other service manual or have any queries: please WRITE to us at [email protected]