Case IH Tractor 9250 Operator’s Manual (9-18513) – PDF Download

FILE DETAILS:

Case IH Tractor 9250 Operator’s Manual_9-18513

Size : 29 MB

Format : PDF

Language : English

Number of Pages : 233 pages

Brand: Case IH

Type of machine: Tractor

Type of document: Operator’s Manual

Model: 9250

Part No: 9-18513

DESCRIPTION:

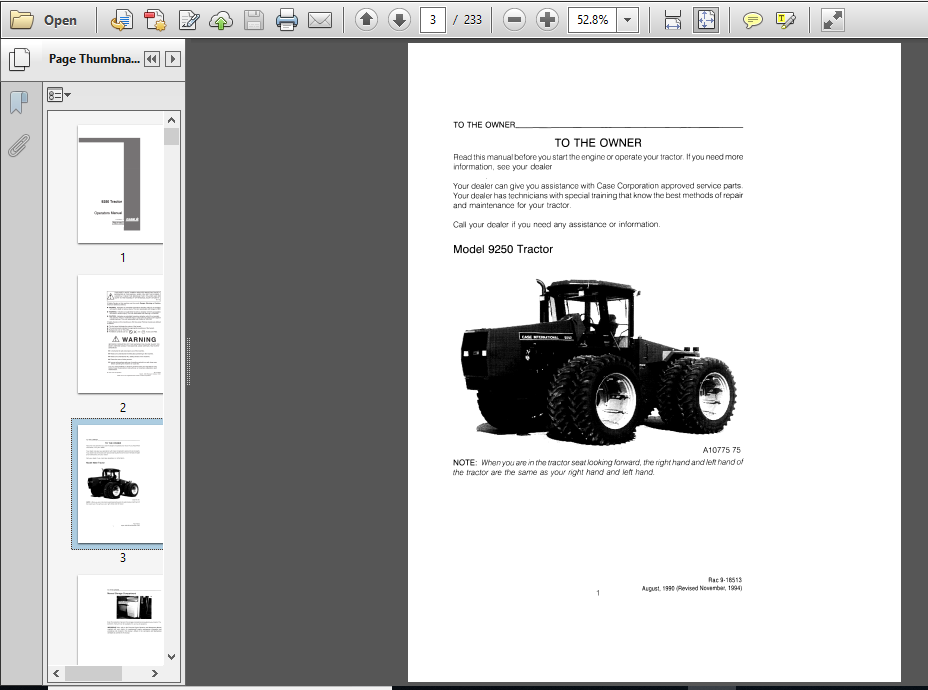

Read this manual before you start the engine or operate y0ur tractor. It you need more information. see your dealer Your dealcr can give you assistance with Case Corporation approved service parts. Your dealer has technicians with special training that know the best methods of repair and maintenance for your tractor. Call your dealer if you need any assistance or information.

General Arrangement and Features :

- The digital instrument cluster (electronic dash) will automatically monitor various operating systems and functions on your tractor. The condition or status of a monitored system will be indicated by readouts on the digital display screens or by indicator lamps. An audible alarm will also sound in conjunction with some indicator lamps or digital displays.

- The indicator lamps are located across the lower part of the instrument cluster. The symbols used to identify the various indicators conform to ISO standards. The operation of the individual indicators is described in this section. See Indicator Lamps on Page 16.

- There are three digital display screens (liquid crystal display) located across the top of the instrument cluster. Information such as ground speed, wheel slip, gear selection, start-up code, system diagnostic codes. engine RPM and PTO RPM will be displayed in digital format. The operation of each display is described in this section. See Digital Display Screens on Page 21.

- Audible Alarm

The digital instrument cluster is equipped with an audible alarm which is activated in conjunction with various system indicator lamps. When activated, the alarm will sound for 2 seconds every 2 minutes or will sound continuously depending on the system being monitored. See Indicator Lamps for more information on alarm operation for specific systems.

- Instrument Cluster Calibration

The digital instrument cluster must be calibrated in the tractor in order to provide accurate information. The cluster must be calibrated anytime there has been a change in tire size, transmission controller or true ground speed sensor. See Digital Instrument Cluster Calibration on Page 107 for complete information.

TABLE OF CONTENTS:

- Case IH Tractor 9250 Operator’s Manual (9-18513)

Safety/Decals

Instruments/Controls

Operating Instructions

Field Operation

Tires/Wheels/Spacing/Ballast

Lubrication/Maintenance Cha

Lubrication/Filters/Fluids

Maintenance/Adjustments

Electrical System

Storagew

Specifications

Detail Index

INDEX DETAILS:

- Case IH Tractor 9250 Operator’s Manual (9-18513)

Accessory Wire Harness Access

Air Conditioning Compressor Belt

Air Conditioning Controls

Air Discharge Louvers

Air Filter, Cab, Recirculating

Air Filter, Cab Outside

Air Filter Cleaning

Air Filter Identification

Air Filter Indicator Lamp Engine

Air Filter Inspection

Air Filter Installation

Air Filter Removal

Air Filter Service Interval

Air Filter Service Monitor

Air Induction System

Air Pressure Tire

Alarm Audible

Alternator Belt

Alternator Charging System

Articulation Only Steering

Ash Tray

Auxiliary Battery Connections

Auxiliary Power Connections

Axle Adjustable, Bar Type

Axle Adjustable, Oil Change

Axle Non Adjustable

Axle Non Adjustable Oil Change

Axle Steerable

Axle Serial Number Location

Ballast, Tractor

Bars Locking Center Hinge

Bar Type Axle

Bar Type Axle Oil Change

Batteries

Batteries Access to

Batteries Auxiliary Connections

Batteries Cables and Terminals

Batteries Not in Use

Batteries Removal and Installation

Before Starting the Engine

Belt Air Conditioner Compressor

Belt, Alternator

Belt, Fan

Belt, Seat

Belt Seat Maintenance

Blocks Sway

Bolt Torques, Wheel

Brake Control Park

Brake Indicator Lamp, Park

Brake Pedal

Brake System

Breakers Circuit, Headliner

Breakers Circuit RH Console

Bulbs and Lamps

Bulbs and Lamps, Replacement

Button Horn

Button, Skip Shift

Cab Door Controls

Cab Outside Air Filter

Cab, Preventive Maintenance

Cab, Recirculating Air Filter

Calibration, Instrument Cluster

Canopy, ROPS Tractors with

Capacities System

Center Hinge Locking Bars

Chain Safety

Charging System Alternator

Chart, Lubrication/Maintenance

Circuit Breakers Headliner

Circuit Breakers, RH Console

Clevis Preparation Drawbar

Clevis Preparation, Drawbar without Three Point Hitch

Cluster Digital Instrument

Cluster Instrument, Calibration

Codes Diagnostic, Hitch Monitor

Codes, Diagnostic, Tractor

Cold Temperature Operation

Column, Steering

Operating Controls

Compartment, Manual Storage

Compressor Belt Air Conditioner

Conditioner Coolant System Filter

Conditioner Fuel

Connecting PTO Driven Euipment

Connecting Remote Hoses

Connecting the Implement Drawbar

Console Lamp replacement

Console Overhead

Console RH Side

Control System Code

Transmission Display Screen

Controller, Transmission

Controls Operating

Coolant Level Indicator

Lamp, Engine

Coolant Level Radiator

Coolant Heater

Coolant Solutions

Coolant System Filter Conditioner

Cooling System

Cooling system DCA Test Kit

Cooling system, Draining

Cooling System, Filling

Cooling System Maintenance

Cooling System, Thermostat

Coupler, Hitch Category IVN

Couplers, Hose

DCA Test Kit

DCA4 Service Requirements

Decals

Decelerator Foot Pedal, Engine

Diagnostic Codes, Tractor

Diagnostic Codes, Transmission

Diagnostic Codes Transmission

Display Screen

Diagnostic Monitor Codes Hitch

Diagnostic Monitor Hitch

Diesel Engine Specifications

Differential Lock Indicator Lamp

Front Axle

Differential Lock Indicator Lamp

Rear Axle

Differential Lock Operation

Differential Lock Switch Front Axle

Differential Lock Switch Rear Axle

Digital Display Screens

Digital Instrument Cluster

Display Screens

Dome Lamp Replacement

Door Controls, Cab

Drain Fuel

Drawbar

Drawbar Clevis Preparation

with Three Point Hitch

Drawbar Clevis Preparation

without Three Point Hitch

Drop Speed Control Hitch Positic

Electrical Specifications

Electronic Hitch Controls

Operation

Electronic Hitch Diagnostic Code

Electronic Hitch System

Emergency Exit Cab

Engine Air Filter

Engine Air Filter Indicator Lamp

Engine Coolant Level

Engine Coolant Level

Indicator Lamp

Engine Coolant Temperature

Gauge

Engine Coolant Temperature

Indicator Lamp

Engine Decelerator Foot Pedal

Engine Lubrication

Engine Oil Change

Engine Oil Filter Change

Engine Oil Level

Engine Oil Pressure Gauge

Engine Oil Viscosity

Engine Serial Number Location

Engine Specifications, Diesel

Engine Speed Display Screen

Engine Starting Procedure

Engine, Stopping the

Ether Start Aid

Ether Start Aid Switch

Exit Emergency, Cab

Fan Belt

Fan Control Lever

Filter Cab Outside Air

Filter Cab Recirculating

Filter, Coolant System Conditioner

Filter Engine Atr

Filter Engine Oil

Filter, Fuel

Filter Hydraulic Oil

Filter Indicator Lamp Engine Air

Filter Indicator Lamp Hydraulic Oil

Filter Indicator Lamp

Transmission Oil

Filter Service Monitor Engine Air

Filter, Transmission Oil

Filters Fluid Levels and

Fittings Lubrication

Float Lockout Lever Remote

Float Mechanical Lower Link

Float Operation, Remote

Flood Lamp Replacement

Flow Control Operation, Remote

Flow Control, Remote

Fluid Levels and Filters

Forward/Reverse Mode

Lever Operation

Forward/Reverse Mode Lever,

Transmission

Front Axle Steering

Fuel Conditioner

Fuel Drain

Fuel Filter Replacement

Fuel Gauge

Fuel Specifications

Fuel System

Gauge, Engine Coolant

Temperature

Gauge Engine Oil Pressure

Gauge Fuel

Gauges, Mechanical

Instrument Panel

Gauges Mechanical

Lamp Replacement

Gear Selection, Transmission,

Display Screen

Gear Selector Lever Transmission

Gear Selector Operation

Grease Fittings

Ground Speed

Ground Speed Display Screen

Ground Speed Sensor, True

Hand Throttle Lever

Harness Access, Accessory Wire

Head Lamp High Beam

Indicator Lamp

Head Lamp Replacement

Heater Controls

Heater, Coolant

High Beam Indicator Lamp

Hinge Locking Bars, Center

Hitch Control, Electronic

Operation

Hitch Coupler Category

Hitch Diagnostic Codes

Hitch Diagnostic Monitor

Hitch Lever Adjustable Stop

Hitch Load Control

Hitch Load Control, Operating in

Hitch Position Control Lever

Hitch Position Control, Operating in

Hitch Position Drop Speed Control

Hitch Preparation Three Point

Hitch Raise/Lower Switch

Hitch Response Speed Control

Hitch System Adjustments

Hitch System Electronic

Hitch Travel Control

Hitch Three Point Operation

Horn button

Hose Couplers

Hoses Remote Connecting

Hourmeter

Hydraulic Motor Operation

Remote

Hydraulic Oil Change

Hydraulic Oil Filter

Hydraulic Oil Filter Indicator Lamp

Hydraulic Oil Level

Hydraulic Oil Service lnterval

Hydraulic Oil Temperature

Indicator Lamp

Hydraulics Remote Operation

Hydraulics, Remote Preparation

Implement, Connecting to Drawbar

Implement Dimensions

Implement, Leveling

Inching Pedal

Inching Pedal Operation

Indicator Lamp, Differential

Lock Front Axle

Indicator Lamp, Differential

Lock Rear Axle

Indicator Lamp, Engine Air Filter

Indicator Lamp Engine

Coolant Level

Indicator Lamp, Engine

Coolant Temperature

Indicator Lamp Engine Oil Pressure

Indicator Lamp High

Beam Head Lamp

Indicator Lamp Hydraulic Oil Filter

Indicator Lamp Hydraulic

Oil Temperature

Indicator Lamp Instrument Cluster

Indicator Lamp Low Voltage

Indicator Lamp Park Brake

Indicator Lamp Transmission

Oil Filter

Indicator Lamp Transmission

Oil Temperature

Indicator Lamp, Turn Signal

Instrument Cluster Calibration

Instrument Cluster, Digital

Instrument Cluster Lamp

Replacement

Instrument Cluster Self Check

Instrument Lamp Switch

Key Switch

Key Switch Release Lever

Lamp and Bulb Replacement

Lamp Replacement, Console

Lamp Replacement Dome

Lamp Replacement Flood

Lamp Replacement,

Gauge Panel Cluster

Lamp Replacement, Head

Lamp Replacement,

Instrument Cluster

Lamp Replacement, Tail

Lamp Replacement, Warning

Lamp Replacement, Work

Lamp Switch, Instrument

Lamp Switch Master, Cab

Lamp Switch, Master, ROPS

Lamps and bulbs

Lamps, Indicator,

Instrument Cluster

Lamps, Warning Implement

Lamps, Warning, Operation

LED Transmission Controller

Leveling an Implement

Levels Flurd

Liquid Tire Weight

Load Capacity Tires

Load Control, Hitch

Load Control Operating in

Lock Lever, Neutral, Remote

Locking Bars, Center Hinge

Louvers Air Discharge

Low Voltage Indicator Lamp

Lower Link Adjustment Hitch

Lower Link Mechanical Float

Lower/Raise Switch, Hitch

Lubrication Analysis, Systemgard

Lubrication Engine Oil

Lubrication Fittings

Lubrication Maintenance Chart

Maintenance Chart, Lubrication

Manual Storage Compartment

Master Lamp Switch, Cab

Master Lamp Switch, ROPS

Measurements Overall

Measuring Wheel Slip

Mechanical Gauges

Mechanical Float, Lower Link

Mirror Rear View

Mode Control Lever, Cab

Air Temperature

Mode Control Lever, Cab

Air Temperature

Mode Lever Forward/Reverse

Transmission

Monitor Air Filter Service

Monitor Diagnostic Hitch

Monitor Mounting

Monitor Power Supply

Mounting Monitors

Neutral Lock Lever Remote

Neutral Lock Operation Remote

Non Adjustable Axle

Non Adjustable Axle Oil Change

Offset Direction Change, Wheel

Oil, Engine

Oil Filter Engine

Oil Filter Indicator Lamp Hydraulic

Oil Filter Indicator Lamp

Transmission

Oil, Hydraulic

Oil Pressure Gauge, Engine

Oil Temperature Indicator

Lamp, Hydraulic

Oil Temperature Indicator

Lamp, Transmission

Operating Controls

Operating Weight Tractor

Maxrmum

Operators Seat maintenance

Operators Seat with Air Suspension

Operator Seat with Mechanical

Suspension

Outlet Seven Terminal

Overall Measurements

Overhead Console Release Knobs

Owner, To The

Park Brake Control

Park Brake Indicator Lamp

PIN Number

Position Control Lever, Hitch

Planetary Oil Change

Position Control, Operating in

Power Shift Transmission

Power Supply Monitor

Power Takeoff

Power Train Specifications

Preparation for Storage

Pressure, Bias Tire

Pressure, Radial Tire

PTO Control Lever

PTO Driven Equipment, Connecting

PTO Operation

PTO Speed Display Screen

Pulser Lever, Transmission

Pulser Operation

Radiator Coolant Level

Radio

Raise/Lower Switch Hitch

Rear View Mirror

Rear Wiper/Washer Switch

Remote Circmts

Remote Control Levers

Remote Float Lockout Lever

Remote Float Operation

Remote Flow Control

Remote Flow Control Operation

Remote Hoses, Connecting

Remote Hydraulic Motor Operation

Remote Hydraulics Operation

Remote Hydraulic Preparation

Remote Neutral Lock Lever

Remote Neutral Lock Operation

Removing from Storage

Response Speed Control Hitch

Reverse/Fonvard Mode Lever Operation

Reverse/Forward Mode

Lever, Transmission

Right Hand Side Console

Rim and Tire Equipment

Rim and Tire Service

Rocker Arm to Valve

Clearance Adjustment

Roll Over Protective Structure

ROPS Canopy Tractors with

ROPS Label

ROPS Safety Rules

Rules, Safety

Run-In Procedure

Safety

Safety Chain

Safety Decals

Safety Rules

Safety Rules, ROPS

Screens, Digital Display

Seat Belt

Seat Belt Maintenance

Seat, Operators Maintenance

Seat, Operators, with

Air Suspension

Seat, Operators with

Mechanical Suspension

Selection Transmission Gear

Display Screen

Selector Lever, Transmission Gear

Sensor True Ground Speed

Serial Number Locations

Seven Terminal Outlet

Shipping Weight, Approximate

Signal, Indicator Lamp, turn

Signal, Turn Lever

Skip Shift Button

Skip Shift Button Operation

Slip Recommendations, Wheel

Slip, Wheel, Display Screen

Slip Wheel Measuring

SMV Symbol

Speed Control, Hitch Position Drop

Speed Control, Hitch Response

Speed, Engine Display Screen

Speed, Ground Display Screen

Speed, PTO Display Screen

Speed Sensor True Ground

Speeds, Travel

Split Bushing Hub Wheel

Adjustment

Start Aid Ether

Start Aid Switch Ether

Starting Procedure, Engine

Starting the Engine Before

Steerable Axle

Steering, Articulation Oniy

Steering, Front Axle

Steering Column, Operating

Controls

Steering Column Telescopic Lever

Steering Column Tilt Lever

Stop, Hitch Lever Adjustable

Stopping the Engine

Storage Compartment Manual

Storage Preparation

Storage, Removing from

Sunvrsor

Sway Blocks

Switch, Raise/Lower Hitch

System Capacities

Systemgard Lubrication Analysis

Tail Lamp Replacement

Telescopic Lever, Steering Column

Temperature Control Lever cab

Temperature Gauge

Engine Coolant

Temperature Indicator Lamp, Engine Coolant

Temperature Indicator Lamp, Hydraulic Oil

Temperature Indicator Lamp

Transmission Oil

Thermostat, Cooling System

Three Point Hitch Operation

Three Point Hitch Preparation

Throttle Lever, Hand

Tilt Lever, Steering Column

Tire and Rim Equipment

Tire and Rim Service

Tire Inflation Procedure

Tire Load Capacity

Tire Pressure, bias

Tire Pressure Radial

Tire Weight Liquid

To the Owner

Torques, Wheel Bolt

Towing Tractor

Tractor Ballast

Tractor Diagnostic Codes

Tractor Roll Over

Tractor Serial Number Location

Tractor Weights

Transmission Control System

Code Display Screen

Transmission Controller

Transmission Controller Diagnostic

Transmission Filter change

Transmission Forward/Reverse Mode Lever

Transmission Gear Selection Display Screen

Transmission Gear Selector Lever

Transmission Oil Change

Transmission Oil Filter

Transmission Oil Filter

Indicator Lamp

Transmission Oil Level

Transmission Oil Temperature

Indicator Lamp

Transmission Power Shift

Transmission Serial Number

Transmission Service Interval

Transporting Tractor

Travel Control, Hitch

Travel Speeds

Tread Position Adjustable Axle

Tread Positions Flange

Bolted Duals

Tread Position Flange

Bolted Triples

Tread Positions, Planetary 13″

Tread Positions Planetary 15″

True Ground Speed Sensor

Turn Signal Indicator Lamp

Turn Signal Lever

Upper Link Adjustment, Hitch

Viscosity, Engine Oil

Voltage Indicator Lamp Low

Voltmeter

Warning Lamp Replacement

Warning Lamp Switch, Hazard

Warning Lamps, Implement

Warning Lamps, Operation

Weight, Approximate Shipping

Weight, Maximum Tractor

Operating

Weight, Tire LIqurd

Wheel Adjustment

Wheel Bolt Torques

Wheel Offset Direction Change

Wheel Slip Display Screen

Wheel Slip, Measuring

Wheel Slip Recommendations

Wheel Tread Positions

Wiper/Washer Switch, Front

Wiper/Washer Switch Rear

Work Lamp Replacement

SCREENSHOT OF THE MANUAL:

VIDEO PREVIEW:

PLEASE NOTE:

⦁ This is the same manual used by the DEALERSHIPS to SERVICE your vehicle.

⦁ The manual can be all yours – Once payment is complete, you will be taken to the download page from where you can download the manual. All in 2-5 minutes time!!

⦁ Need any other service / repair / parts manual, please feel free to contact us at heydownloadss @gmail.com . We may surprise you with a nice offer