Case IH Tractor Steiger 350,400,450,500,550,600 Quadtrac 450,500,550,600 Operator’s Manual

FILE DETAILS:

Case IH Tractor Steiger 350,400,450,500,550,600 Quadtrac 450,500,550,600 Operator’s Manual_84295156

Size : 51.7 MB

Format : PDF

Language : English

Number of Pages : 456 pages

Brand: Case IH

Type of machine: Tractor

Type of document: Operator’s Manual

Model: Steiger 350,400,450,500,550,600 Quadtrac 450,500,550,600

Part No: 84295156

DESCRIPTION:

Case IH Steiger 350, Steiger 400, Steiger 450, Steiger 500, Steiger 550, Steiger 600 Tractors Operator`s Manual. Case IH Steiger 350,400,450,500,550,600 Quadtrac 450,500,550,600 Operator`s Manual

- Manuals are available from your dealer for your machine. Your dealer can expedite your order for operator manuals and parts catalogs. Always give the machine name. model and P.I.N. (product identification number) of your machine so your dealer can provide the correct manuals for your machine. The company is continually striving to improve its prod- ucts and therefore reserves the right to make improve- ments and changes when it becomes practical and pos- sible to do so.

- without incurring any obligation to make changes or additions to the equipment sold previously. Manual scope and required training level This manual provides information on the intended use of your tractor under the conditions foreseen by the man- ufacturer during normal operation.

- routine service and maintenance and periodic service and maintenance. Normal operation is use of the tractor for the purpose in- tended by the manufacturer by an ownerloperator who is familiar with the tractor and the mounted or towed equip- ment. and who is complying with the information on oper- ation and safe practices. provided in this manual and by the decals on the tractor and the equipment. Normal operation includes such actions as preparing the tractor for storage and removing the tractor from storage. adding or removing ballast connecting and disconnect- ing mounted or towed equipment. raising and lowering components into or out of work position. adjusting tractor settings for specific field or crop settings. etc. Routine service and maintenance are those actions which must be performed dafly to maintain proper tractor func- tion by an ownedoperatorwho is famfliarwith tractor char- acteristics. and who is complying with the information on routine service and safe practices in this manual and in the decals on the tractor. Routine service and maintenance includes such actions as fueling. cleaning. washing. topping off fluid levels. greasing. and replacing consumable articles such as lamp bulbs.

- Periodic service and maintenance are those actions which must be performed at regularly defined intervals [HM 0313 gNen In this manual IS SUBJECI IO prooucuon van- atrons. NOTICE: Operating and service messages displayed on the eIectronic operating panel may vary fi’om what is shown in the manual. If this occurs, heed die latest instructions on the electronic operating panel. Dimensions and weights are approximate only and the illustrations do not necessarily show the machine in stan- dard condition. For exact information about any particular machine.

- please consult your dealer. to maintain proper tractor function by an owner/operator who is familiar with tractor characteristics. and who is complying with the information on periodic service and safe practices in this manual and in the decals on the tractor. Periodic service and maintenance includes such actions as checking. cleaning and changing air filters. changing engine oil and filters. changing transmission oil and fil- ters. changing front axle and wheel hub fluids. changing coolant. etc. Some actions in the periodic service and maintenance chart are beyond the knowledge and skills of the owner] operator: for example.

- engine valve adjustment. fuel in- jector nozles. For these actions. the manual instructs the ovmerloperator to have the action performed by their authorized dealer. This manual does not contain all the information related to periocfical service and maintenance. converting and re- pairs to be carried out by professional service personnel.

- These actions require special facilities. technical skills. and/or tools which are not supplied with the machine. Converting is changing the tractor configuration for a specific crop or soil condition and requires rebuilding or adding components to the vehicle: for example. instal- lation of dual wheels. Repairing is the disassembly and assembly of the tractor to restore proper operation after a component failure or degradation of performance.

IMAGES:

VIDEO PREVIEW:

TABLE OF CONTENTS:

Case IH Tractor Steiger 350,400,450,500,550,600 Quadtrac 450,500,550,600 Operator’s Manual

1 GENERAL INFORMATION

Read the Operators Manual 1-1

Engine tampering 1-1

CNH America LLC technical manuals 1-2

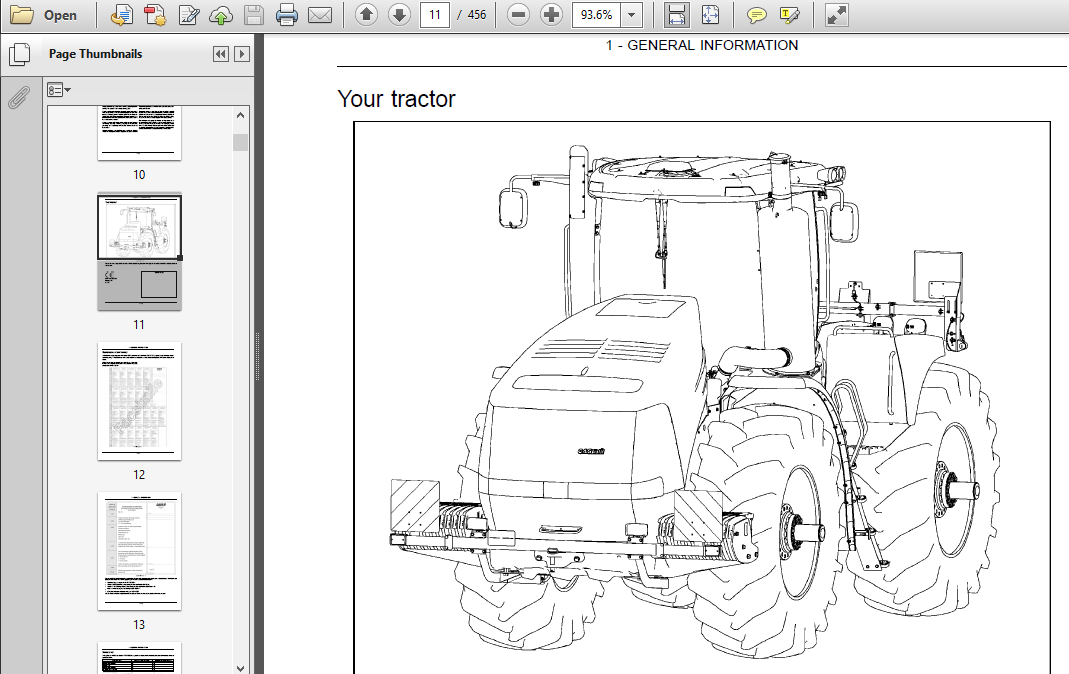

Your tractor 1-3

Declaration of conformity1-4

Noise level 1-6

Vehicle vibration levels 1-7

Note to the Owner 1-8

Tractor intended use1-8

Manual storage 1-9

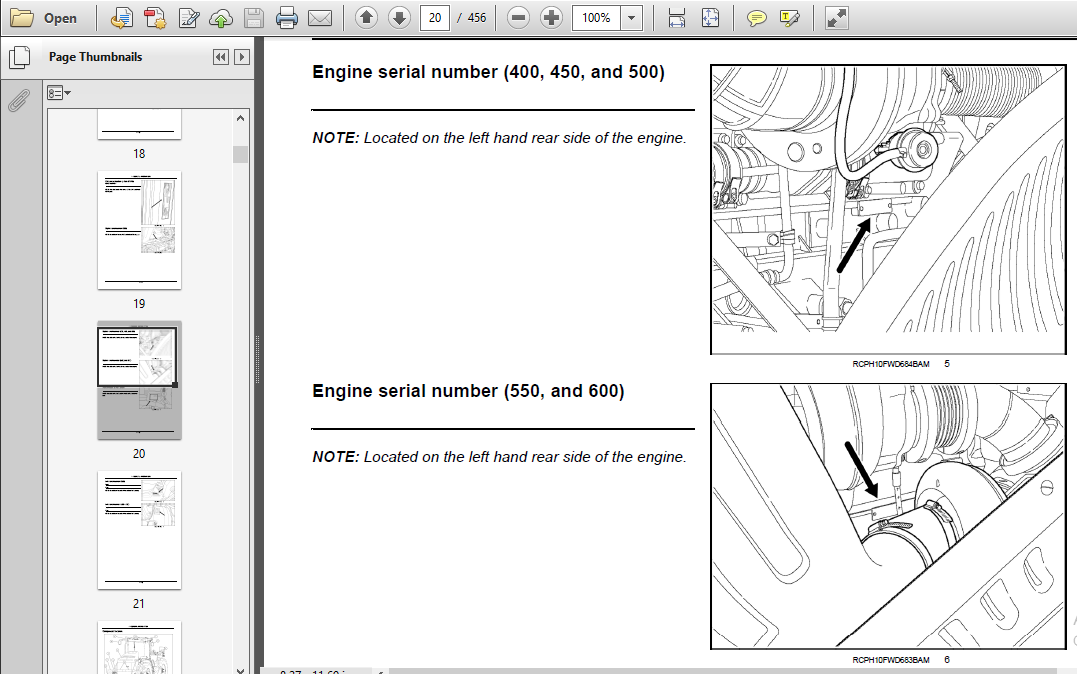

Product identification 1-10

Component location1-14

2 SAFETY INFORMATION

Safety rules and signal word definitions2-1

Safety rules – General 2-2

Safety rules – Mounting and dismounting 2-3

Safety rules – Implements, tools and trailers2-3

Safety rules – Instructional seat 2-4

Safety rules – Wheels and tires 2-4

Safety rules – Fire prevention 2-5

Safety rules – Fire extinguisher 2-5

Safety rules – PTO operation 2-6

Safety rules – General maintenance2-7

Safety rules – Battery 2-8

Safety rules – Basic operating 2-9

Safety rules – Hazardous chemicals 2-10

Safety rules – Air conditioning system 2-10

Safety rules – Operator presence system 2-10

Safety rules – Roll over and tip over 2-11

Safety rules – Electrical storm safety 2-11

Safety rules – Driving on public roads 2-12

Safety rules – Utility power lines 2-12

Safety rules – Hydraulic system safety 2-13

ROPS and FOPS 2-14

Hazardous substances 2-15

Emergency exit 2-15

Safety decals 2-16

Articulation cylinder locking blocks 2-25

DEF/AdBlue® safety signs 2-26

3 CONTROLS/INSTRUMENTS

OPERATOR’S SEAT

Overview3-1

Control identification3-2

INSTRUCTOR’S SEAT

Overview3-5

FORWARD CONTROLS

Steering column 3-7

Front console 3-10

Pedal controls 3-11

Ventilation 3-12

Front sun shade3-13

RIGHT-HAND SIDE CONTROLS

Armrest console3-14

Multi Function Handle 3-14

Control panel 3-18

Remote valve controls 3-25

Joystick 3-26

Armrest compartment 3-27

Adjusting the armrest console 3-29

REARWARD CONTROLS

Rear sun shade3-30

OVERHEAD CONTROLS

Overview 3-31

Automatic temperature controls3-33

Automatic temperature control system 3-37

Center panel controls 3-39

Radio (if equipped) 3-43

Interior and access lights 3-43

EXTERIOR CONTROLS

Exterior hitch control 3-46

INSTRUMENT CLUSTER

Overview 3-47

Gauges 3-47

Status and warning icons 3-48

Upper display 3-51

DEF/AdBlue® level 3-52

Lower display 3-53

Keypad 3-55

Instrumentation – setup menu 3-57

Instrumentation – adjust menu 3-64

Performance instrumentation 3-71

4 OPERATING INSTRUCTIONS

COMMISSIONING THE UNIT

Before starting the engine 4-1

STARTING THE UNIT

Normal engine starting 4-5

Cold temperature operation 4-7

STOPPING THE UNIT

Stopping the engine 4-9

MOVING THE UNIT

Powershift transmission4-11

Selective catalytic reduction (SCR) system4-19

Automatic productivity management (APM)4-24

Differential lock system 4-33

Constant engine speed 4-34

Electronic end of row system 4-37

Engine compression brake (if equipped) 4-47

5 TRANSPORT OPERATIONS

ROAD TRANSPORT

Tractor warning lamps 5-1

Operating the tractor warning lamps5-3

Safe transport speed5-4

Implement warning lamps 5-5

Safety chain 5-6

SHIPPING TRANSPORT

Securing the tractor for shipping5-7

RECOVERY TRANSPORT

Safety rules 5-8

Towing the tractor 5-9

6 WORKING OPERATIONS

GENERAL INFORMATION

Product overview6-1

REAR PTO

Safety rules 6-2

Connecting the PTO 6-4

PTO operation 6-5

THREE POINT HITCH

Identification 6-7

Link adjustment 6-8

Sway block adjustment 6-10

Mechanical float adjustment 6-11

Hitch quick coupler – Category IVN6-12

Transport lock 6-16

Hitch operation 6-17

Rear remote hitch switch 6-21

Position control operation 6-22

Slip control operation 6-25

DRAWBARS AND TOWING ATTACHMENTS

Safety rules 6-27

Rear towing – Capacities 6-27

Scraper operation 6-33

TRAILER BRAKE COUPLER

Safety rules 6-34

Trailer brake connections 6-34

AUXILIARY POWER CONNECTIONS

External power and lighting connections 6-35

Cab power connections6-37

HYDRAULIC REMOTE CONTROL VALVES

Valve couplers and connections6-40

Optional circuits6-46

Hydraulic remote valve transport lock 6-47

Operating the controls 6-48

Remote valve display screens 6-52

Joystick operation 6-55

Auto auxiliary mode operation 6-60

Auto depth control operation 6-63

BALLASTING THE TRACTOR

Guidelines 6-66

Weights, cast metal and liquid Front Ballast 6-70

Wheel slip and power hop 6-76

FRONT AND REAR AXLE

Tire safety 6-77

Pressure and load ratings 6-78

Wheel installation 6-84

Wheel tread settings 6-90

Track preconditioning 6-101

7 MAINTENANCE

GENERAL INFORMATION

Safety rules 7-1

Engine hood 7-2

Removing the engine side shields 7-3

Opening the right hand service door7-4

Power cut-off switch 7-4

Filling the fuel tank 7-6

Fuel tank capacity 7-7

Filling the DEF/AdBlue® tank 7-8

DEF/AdBlue® tank capacity 7-9

Tire and rim service7-10

Tractor jacking points 7-12

Capacities 7-14

Consumables – Engine oil 7-15

Consumables – Biodiesel fuel 7-17

Consumables – Diesel exhaust fluid (DEF)/AdBlue® 7-19

Consumables – Coolant solutions 7-21

Electrical specifications and service 7-22

Fuse and relay locations 7-24

Maintenance chart notes 7-32

MAINTENANCE CHART

Maintenance Chart 7-33

AT WARNING MESSAGE DISPLAY

Air cleaner 7-35

Fuel filter 7-36

EVERY 10 HOURS OR EACH DAY

Engine oil level 7-37

Wheel bolt torque 7-37

Wheel weight bolt torque 7-37

Transmission oil level 7-38

Hydraulic/axle oil level 7-39

Engine coolant level7-40

Fuel level 7-40

General tractor inspection (see Note 1)7-41

EVERY 50 HOURS

Fuel tank and fuel filter 7-42

Articulation hinge – upper front 7-44

Oscillation hinge – rear 7-44

Articulation hinge – lower 7-44

Articulation cylinder – front, left hand, right hand 7-45

Articulation cylinder – rear, left hand and right hand7-45

Hitch cylinder pin – upper, left hand and right hand7-46

Hitch cylinder pin – lower, left hand and right hand 7-46

Hitch rockshaft – left hand and right hand 7-47

Hitch lift links and top link 7-47

EVERY 250 HOURS

Cab air filter, outside (see Note 2) 7-48

Cab recirculation filter 7-49

Windshield washer fluid level 7-50

Driveshaft carrier bearing 7-50

EVERY 500 HOURS

Air tubing – engine 7-51

Alternator – water pump belt7-51

Battery electrolyte level7-52

PTO carrier bearing7-53

PTO slip joint 7-53

Radiator and coolers 7-54

EVERY 600 HOURS

Engine oil and filter (see note 5) 7-56

Engine fuel filter (see note 6) 7-59

Engine fuel pre-filter7-63

DEF/AdBlue® in-line filter 7-68

Fuel tank vent (see note 8) 7-71

EVERY 1200 HOURS

Engine crankcase breather filter 7-72

DEF/AdBlue® supply module filters7-74

EVERY 1500 HOURS

Engine air tubing 7-79

Engine air filters (see Note 3) 7-80

Hydraulic oil and filters (see note 6)7-86

Hydraulic reservoir breather7-88

Transmission oil and filter (see note 6) 7-89

Transmission vent 7-90

Idler/roller wheel oil (see Note 7) 7-91

Cab air filter, outside (see Note 2) 7-92

Door lock and hinges (see Note 4) 7-93

EVERY 2000 HOURS OR 2 YEARS

Engine coolant drain and flush 7-94

AS REQUIRED

Vehicle fire prevention 7-97

Pressure cooling system hoses7-98

Hydraulic system hoses7-98

Tire pressure 7-98

Engine fan belt 7-98

Viscous fan drive 7-99

Track inspection and bolt torque 7-100

Track tension release 7-102

Track belt alignment 7-104

Cab fabric and carpet 7-106

Seat belt 7-106

STORAGE

Placing in storage 7-107

Removing from storage 7-107

ELECTRICAL SYSTEM

Battery removal and installation 7-108

Auxiliary battery connections 7-109

Hood lamp replacement 7-111

Flood and work lamp replacement7-116

Rotating beacon lamp replacement 7-121

Interior lights lamp replacement 7-122

8 TROUBLESHOOTING

FAULT CODE RESOLUTION

Fault code retrieval 8-1

ALARM(S)

Display warnings8-2

9 SPECIFICATIONS

Engine 9-1

Power train and hydraulics 9-3

Speed charts9-6

Vehicle dimensions and shipping weight9-9

Maximum tractor operating weights9-13

10 ACCESSORIES

Farming system Monitor – Install 10-1

Chemical tank mounting 10-2

General accessories

INDEX DETAILS:

Case IH Tractor Steiger 350,400,450,500,550,600 Quadtrac 450,500,550,600 Operator’s Manual

ACCESSORIES 10-1

Business band radios-

Chemical tank mounting 10-2

Extendable mirrors –

Farming system Monitor – Install10-1

General accessories 10-5

Interior rear view mirror –

ALARM(S)8-2

Display warnings 8-2

AS REQUIRED7-97

Cab fabric and carpet 7-106

Engine fan belt7-98

Hydraulic system hoses 7-98

Pressure cooling system hoses 7-98

Seat belt 7-106

Tire pressure 7-98

Track belt alignment7-104

Track inspection and bolt torque 7-100

Track tension release 7-102

Vehicle fire prevention7-97

Viscous fan drive 7-99

AT WARNING MESSAGE DISPLAY 7-35

Air cleaner 7-35

Fuel filter 7-36

AUXILIARY POWER CONNECTIONS6-35

Cab power connections 6-37

External power and lighting connections 6-35

BALLASTING THE TRACTOR 6-66

Guidelines 6-66

Weights, cast metal and liquid Front Ballast 6-70

Wheel slip and power hop 6-76

COMMISSIONING THE UNIT4-1

Before starting the engine4-1

CONTROLS/INSTRUMENTS 3-1

Adjusting the armrest console 3-29

Armrest compartment3-27

Armrest console 3-14

Automatic temperature control system 3-37

Automatic temperature controls3-33

Center panel controls3-39

Control identification 3-2

Control panel 3-18

DEF/AdBlue® level 3-52

Exterior hitch control 3-46

Front console 3-10

Front sun shade 3-13

Gauges3-47

Instrumentation – adjust menu 3-64

Instrumentation – setup menu 3-57

Interior and access lights3-43

Joystick3-26

Keypad3-55

Lower display 3-53

Multi Function Handle3-14

Overview3-1

Overview3-5

Overview 3-31

Overview 3-47

Pedal controls 3-11

Performance instrumentation3-71

Radio (if equipped) 3-43

Rear sun shade 3-30

Remote valve controls 3-25

Status and warning icons3-48

Steering column3-7

Upper display 3-51

Ventilation 3-12

DRAWBARS AND TOWING ATTACHMENTS 6-27

Rear towing – Capacities6-27

Safety rules6-27

Scraper operation6-33

ELECTRICAL SYSTEM 7-108

Auxiliary battery connections 7-109

Battery removal and installation 7-108

Flood and work lamp replacement7-116

Hood lamp replacement7-111

Interior lights lamp replacement 7-122

Rotating beacon lamp replacement 7-121

EVERY 10 HOURS OR EACH DAY 7-37

Engine coolant level 7-40

Engine oil level7-37

Fuel level 7-40

General tractor inspection (see Note 1)7-41

Hydraulic/axle oil level 7-39

Transmission oil level7-38

Wheel bolt torque 7-37

Wheel weight bolt torque7-37

EVERY 1200 HOURS 7-72

DEF/AdBlue® supply module filters7-74

Engine crankcase breather filter7-72

EVERY 1500 HOURS 7-79

Cab air filter, outside (see Note 2) 7-92

Door lock and hinges (see Note 4) 7-93

Engine air filters (see Note 3) 7-80

Engine air tubing 7-79

Hydraulic oil and filters (see note 6)7-86

Hydraulic reservoir breather 7-88

Idler/roller wheel oil (see Note 7) 7-91

Transmission oil and filter (see note 6)7-89

Transmission vent7-90

EVERY 2000 HOURS OR 2 YEARS 7-94

Engine coolant drain and flush 7-94

EVERY 250 HOURS7-48

Cab air filter, outside (see Note 2) 7-48

Cab recirculation filter7-49

Driveshaft carrier bearing7-50

Windshield washer fluid level7-50

EVERY 50 HOURS 7-42

Articulation cylinder – front, left hand, right hand 7-45

Articulation cylinder – rear, left hand and right hand 7-45

Articulation hinge – lower7-44

Articulation hinge – upper front 7-44

Fuel tank and fuel filter 7-42

Hitch cylinder pin – lower, left hand and right hand 7-46

Hitch cylinder pin – upper, left hand and right hand 7-46

Hitch lift links and top link7-47

Hitch rockshaft – left hand and right hand 7-47

Oscillation hinge – rear 7-44

EVERY 500 HOURS7-51

Air tubing – engine7-51

Alternator – water pump belt 7-51

Battery electrolyte level 7-52

PTO carrier bearing 7-53

PTO slip joint 7-53

Radiator and coolers 7-54

EVERY 600 HOURS7-56

DEF/AdBlue® in-line filter7-68

Engine fuel filter (see note 6)7-59

Engine fuel pre-filter 7-63

Engine oil and filter (see note 5)7-56

Fuel tank vent (see note 8) 7-71

EXTERIOR CONTROLS 3-46

Exterior hitch control 3-46

FAULT CODE RESOLUTION 8-1

Fault code retrieval8-1

FORWARD CONTROLS3-7

Front console 3-10

Front sun shade 3-13

Pedal controls 3-11

Steering column3-7

Ventilation 3-12

FRONT AND REAR AXLE6-77

Pressure and load ratings 6-78

Tire safety 6-77

Track preconditioning 6-101

Wheel installation 6-84

Wheel tread settings 6-90

GENERAL INFORMATION1-1

CNH America LLC technical manuals 1-2

Component location 1-14

Declaration of conformity 1-4

Engine tampering 1-1

Manual storage1-9

Noise level 1-6

Note to the Owner 1-8

Product identification 1-10

Read the Operators Manual 1-1

Tractor intended use 1-8

Vehicle vibration levels1-7

Your tractor 1-3

GENERAL INFORMATION6-1

Product overview 6-1

GENERAL INFORMATION7-1

Capacities 7-14

Consumables – Coolant solutions 7-21

Consumables – Engine oil 7-15

Consumables – Biodiesel fuel 7-17

Consumables – Diesel exhaust fluid (DEF)/AdBlue®7-19

Cooling system-

DEF/AdBlue® tank capacity 7-9

Electrical specifications and service7-22

Engine hood7-2

Filling the DEF/AdBlue® tank7-8

Filling the fuel tank 7-6

Fuel tank capacity 7-7

Fuse and relay locations 7-24

Maintenance chart notes7-32

Opening the right hand service door7-4

Power cut-off switch 7-4

Removing the engine side shields 7-3

Safety rules 7-1

Tire and rim service 7-10

Tractor jacking points7-12

HYDRAULIC REMOTE CONTROL VALVES 6-40

Auto auxiliary mode operation 6-60

Auto depth control operation6-63

Hydraulic remote valve transport lock 6-47

Joystick operation6-55

Operating the controls6-48

Optional circuits 6-46

Remote valve display screens 6-52

Valve couplers and connections6-40

INSTRUCTOR’S SEAT 3-5

Overview3-5

INSTRUMENT CLUSTER 3-47

DEF/AdBlue® level 3-52

Gauges3-47

Instrumentation – adjust menu 3-64

Instrumentation – setup menu 3-57

Keypad3-55

Lower display 3-53

Overview 3-47

Performance instrumentation3-71

Status and warning icons3-48

Upper display 3-51

MAINTENANCE7-1

Air cleaner 7-35

Air tubing – engine7-51

Alternator – water pump belt 7-51

Articulation cylinder – front, left hand, right hand 7-45

Articulation cylinder – rear, left hand and right hand 7-45

Articulation hinge – lower7-44

Articulation hinge – upper front 7-44

Auxiliary battery connections 7-109

Battery electrolyte level 7-52

Battery removal and installation 7-108

Cab air filter, outside (see Note 2) 7-48

Cab air filter, outside (see Note 2) 7-92

Cab fabric and carpet 7-106

Cab recirculation filter7-49

Capacities 7-14

Consumables – Coolant solutions 7-21

Consumables – Engine oil 7-15

Consumables – Biodiesel fuel 7-17

Consumables – Diesel exhaust fluid (DEF)/AdBlue®7-19

Cooling system-

DEF/AdBlue® in-line filter7-68

DEF/AdBlue® supply module filters7-74

DEF/AdBlue® tank capacity 7-9

Door lock and hinges (see Note 4) 7-93

Driveshaft carrier bearing7-50

Electrical specifications and service7-22

Engine air filters (see Note 3) 7-80

Engine air tubing 7-79

Engine coolant drain and flush 7-94

Engine coolant level 7-40

Engine crankcase breather filter7-72

Engine fan belt7-98

Engine fuel filter (see note 6)7-59

Engine fuel pre-filter 7-63

Engine hood7-2

Engine oil and filter (see note 5)7-56

Engine oil level7-37

Filling the DEF/AdBlue® tank7-8

Filling the fuel tank 7-6

Flood and work lamp replacement7-116

Fuel filter 7-36

Fuel level 7-40

Fuel tank and fuel filter 7-42

Fuel tank capacity 7-7

Fuel tank vent (see note 8) 7-71

Fuse and relay locations 7-24

General tractor inspection (see Note 1)7-41

Hitch cylinder pin – lower, left hand and right hand 7-46

Hitch cylinder pin – upper, left hand and right hand 7-46

Hitch lift links and top link7-47

Hitch rockshaft – left hand and right hand 7-47

Hood lamp replacement7-111

Hydraulic oil and filters (see note 6)7-86

Hydraulic reservoir breather 7-88

Hydraulic system hoses 7-98

Hydraulic/axle oil level 7-39

Idler/roller wheel oil (see Note 7) 7-91

Interior lights lamp replacement 7-122

Maintenance Chart 7-33

Maintenance chart notes7-32

Opening the right hand service door7-4

Oscillation hinge – rear 7-44

Placing in storage 7-107

Power cut-off switch 7-4

Pressure cooling system hoses 7-98

PTO carrier bearing 7-53

PTO slip joint 7-53

Radiator and coolers 7-54

Removing from storage7-107

Removing the engine side shields 7-3

Rotating beacon lamp replacement 7-121

Safety rules 7-1

Seat belt 7-106

Tire and rim service 7-10

Tire pressure 7-98

Track belt alignment7-104

Track inspection and bolt torque 7-100

Track tension release 7-102

Tractor jacking points7-12

Transmission oil and filter (see note 6)7-89

Transmission oil level7-38

Transmission vent7-90

Vehicle fire prevention7-97

Viscous fan drive 7-99

Wheel bolt torque 7-37

Wheel weight bolt torque7-37

Windshield washer fluid level7-50

MAINTENANCE CHART 7-33

Maintenance Chart 7-33

MOVING THE UNIT 4-11

Automatic productivity management (APM) 4-24

Constant engine speed 4-34

Differential lock system 4-33

Electronic end of row system4-37

Engine compression brake (if equipped) 4-47

Powershift transmission 4-11

Selective catalytic reduction (SCR) system4-19

OPERATING INSTRUCTIONS4-1

Automatic productivity management (APM) 4-24

Before starting the engine4-1

Cold temperature operation 4-7

Constant engine speed 4-34

Differential lock system 4-33

Electronic end of row system4-37

Engine compression brake (if equipped) 4-47

Normal engine starting4-5

Powershift transmission 4-11

Selective catalytic reduction (SCR) system4-19

Stopping the engine 4-9

OPERATOR’S SEAT 3-1

Control identification 3-2

Overview3-1

OVERHEAD CONTROLS 3-31

Automatic temperature control system 3-37

Automatic temperature controls3-33

Center panel controls3-39

Interior and access lights3-43

Overview 3-31

Radio (if equipped) 3-43

REAR PTO 6-2

Connecting the PTO 6-4

PTO operation 6-5

Safety rules 6-2

REARWARD CONTROLS3-30

Rear sun shade 3-30

RECOVERY TRANSPORT5-8

Safety rules 5-8

Towing the tractor 5-9

RIGHT-HAND SIDE CONTROLS 3-14

Adjusting the armrest console 3-29

Armrest compartment3-27

Armrest console 3-14

Control panel 3-18

Joystick3-26

Multi Function Handle3-14

Remote valve controls 3-25

ROAD TRANSPORT 5-1

Implement warning lamps5-5

Operating the tractor warning lamps5-3

Safe transport speed 5-4

Safety chain5-6

Tractor warning lamps 5-1

SAFETY INFORMATION2-1

Articulation cylinder locking blocks 2-25

DEF/AdBlue® safety signs 2-26

Emergency exit 2-15

Hazardous substances 2-15

ROPS and FOPS 2-14

Safety decals 2-16

Safety rules – Air conditioning system 2-10

Safety rules – Basic operating2-9

Safety rules – Battery 2-8

Safety rules – Driving on public roads 2-12

Safety rules – Electrical storm safety 2-11

Safety rules – Fire extinguisher 2-5

Safety rules – Fire prevention2-5

Safety rules – General2-2

Safety rules – General maintenance2-7

Safety rules – Hazardous chemicals 2-10

Safety rules – Hydraulic system safety2-13

Safety rules – Implements, tools and trailers 2-3

Safety rules – Instructional seat 2-4

Safety rules – Mounting and dismounting 2-3

Safety rules – Operator presence system 2-10

Safety rules – PTO operation 2-6

Safety rules – Roll over and tip over2-11

Safety rules – Utility power lines2-12

Safety rules – Wheels and tires 2-4

Safety rules and signal word definitions2-1

SHIPPING TRANSPORT 5-7

Securing the tractor for shipping 5-7

SPECIFICATIONS9-1

Engine 9-1

Maximum tractor operating weights9-13

Power train and hydraulics9-3

Speed charts 9-6

Vehicle dimensions and shipping weight9-9

STARTING THE UNIT4-5

Cold temperature operation 4-7

Normal engine starting4-5

STOPPING THE UNIT 4-9

Stopping the engine 4-9

STORAGE 7-107

Placing in storage 7-107

Removing from storage7-107

THREE POINT HITCH 6-7

Hitch operation6-17

Hitch quick coupler – Category IVN 6-12

Identification6-7

Link adjustment6-8

Mechanical float adjustment6-11

Position control operation6-22

Rear remote hitch switch6-21

Slip control operation6-25

Sway block adjustment 6-10

Transport lock 6-16

TRAILER BRAKE COUPLER6-34

Safety rules6-34

Trailer brake connections6-34

TRANSPORT OPERATIONS 5-1

Implement warning lamps5-5

Operating the tractor warning lamps5-3

Safe transport speed 5-4

Safety chain5-6

Safety rules 5-8

Securing the tractor for shipping 5-7

Towing the tractor 5-9

Tractor warning lamps 5-1

TROUBLESHOOTING 8-1

Display warnings 8-2

Fault code retrieval8-1

WORKING OPERATIONS 6-1

Auto auxiliary mode operation 6-60

Auto depth control operation6-63

Cab power connections 6-37

Connecting the PTO 6-4

External power and lighting connections 6-35

Guidelines 6-66

Hitch operation6-17

Hitch quick coupler – Category IVN 6-12

Hydraulic remote valve transport lock 6-47

Identification6-7

Joystick operation6-55

Link adjustment6-8

Mechanical float adjustment6-11

Operating the controls6-48

Optional circuits 6-46

Position control operation6-22

Pressure and load ratings 6-78

Product overview 6-1

PTO operation 6-5

Rear remote hitch switch6-21

Rear towing – Capacities6-27

Remote valve display screens 6-52

Safety rules 6-2

Safety rules6-27

Safety rules6-34

Scraper operation6-33

Slip control operation6-25

Sway block adjustment 6-10

Tire safety 6-77

Track preconditioning 6-101

Trailer brake connections6-34

Transport lock 6-16

Valve couplers and connections6-40

Weights, cast metal and liquid Front Ballast 6-70

Wheel installation 6-84

Wheel slip and power hop 6-76

Wheel tread settings

PLEASE NOTE:

⦁ This is the SAME manual used by the dealers to troubleshoot any faults in your vehicle. This can be yours in 2 minutes after the payment is made.

⦁ Contact us at [email protected] should you have any queries before your purchase or that you need any other service / repair / parts operators manual.