Case IH New Holland TD 60D 70D 80D 90D 95D Operators Manual

FILE DETAILS:

LANGUAGE:ENGLISH

PAGES:209

FILE TYPPE:PDF

DOWNLOADABLE:YES

DESCRIPTION:

NEW HOLLAND TD60D, TD70D, TD80D, TD90D, TD95D OPERATOR`S MANUAL

- This tractor complies strictly with the European Regulations on electro-magnetic emissions. However, interference may arise as a result of add-on equipment which may not necessarily meet the required standards. As such interference can result in serious malfunction of the unit and/or create unsafe situations, you must observe the following:

- Ensure that each piece of non-New Holland equipment fitted to the tractor bears the CE mark.

- The maximum power of emission equipment (radio, telephones, etc.) must not exceed the limits imposed by the national authorities of the country where you use the tractor.

- The electro-magnetic field generated by the add-on system should not exceed 24 V/m at any time and at any location in the proximity of electronic components. Failure to comply with these rules will render the New Holland warranty null and void.

- TO THE OWNER GENERAL This Manual has been prepared to assist you in the correct procedure for running–in, driving and operating and for the maintenance of your new tractor. Read this Manual carefully. Your tractor is intended for use in normal and customary agricultural applications. If at any time you require advice concerning your tractor, do not hesitate to contact your New Holland dealer. He has factory trained personnel, genuine manufacturers’ parts and the necessary equipment to carry out all your service requirements. Your tractor has been designed and built to give maximum performance, economy and ease of operation under a wide variety of operating conditions. Prior to delivery, the tractor was carefully inspected, both at the factory and by your dealer to ensure that it reaches you in optimum condition. To maintain this condition and ensure trouble–free operation, it is important that the routine services, as specified in Section 4 of this Manual, are carried out at the recommended intervals.

- CLEANING THE TRACTOR Your tractor is a state-of-the-art machine with sophisticated controls. This should be borne in mind when cleaning the tractor, particularly if using a high pressure washer. Even though every precaution has been taken to safeguard electrical components and connections, the pressure generated by some of these machines is such that complete protection against water ingress cannot be guaranteed. When using a high pressure washer, do not stand too close to the tractor and avoid directing the jet at electronic components, electrical connections, breathers, seals, filler caps, etc. Never direct a cold water jet at a hot engine or exhaust. SAFETY Pages 1–6 to 1–11 inclusive list the precautions to be observed to ensure your safety and the safety of others. Read the safety precautions and follow the advice offered before operating the tractor.

- FIRST 50 HOUR SERVICE In Section 9, at the back of this Manual, you will find the 50–hour service reports. After you have operated the tractor for 50 hours, take your tractor, together with this Manual, to your dealer. He will then perform the factory recommended 50– hour service and complete the service report sheets (pages 9–1 and 9–3). The first sheet (page 9–1) is the dealer’s copy and should be removed by the dealer after the service has been carried out. The second sheet (page 9–3) is your copy of the service performed. Ensure that you and the dealer sign both copies.

- SERVICE PARTS It should be pointed out that genuine parts have been examined and approved by the Company. The installation and/or use of ‘non-genuine’ products could have negative effects upon the design characteristics of your tractor and thereby affect it’s safety. The Company is not liable for any damage caused by the use of ‘non–genuine’ parts and accessories. Only genuine replacement parts should be used. The use of non-genuine parts may invalidate legal approvals associated with this product. It is prohibited to carry out any modifications to the tractor unless specifically authorised, in writing, by the After Sales Service department of the Company. WARRANTY Your tractor is warranted according to legal rights in your country and the contractual agreement with the selling dealer. No warranty shall, however, apply if the tractor has not been used, adjusted and maintained according to the instructions given in the Operator’s Manual.

IMAGES:

VIDEO PREVIEW:

TABLE OF CONTENTS:

Case IH New Holland TD 60D 70D 80D 90D 95D Operators Manual

Section 1 – General Information and Safety

To the owner 1–1

Tractor identification 1–2

Ecology and the environment 1–5

Safety precautions 1–6

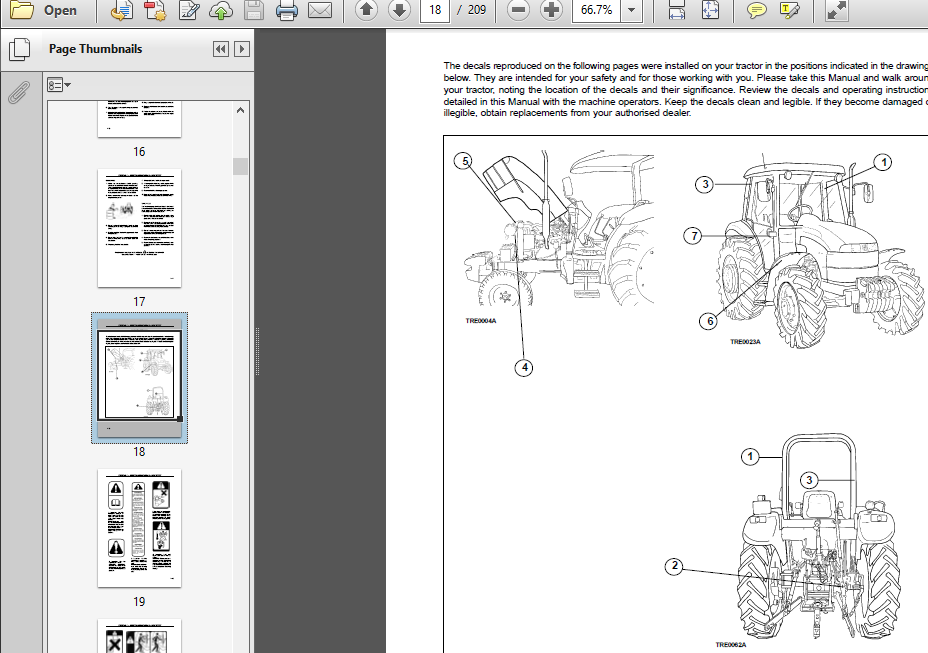

Safety decals 1–12

International symbols 1–15

Section 2 – Controls, Instruments and Operation

Safety covers and guards2–2

Controls and instruments2–4

Instrument panel 2–5

Instrument console controls 2–11

Right–hand side operating controls 2–12

Left–hand side operating controls 2–13

Cab controls2–15

Seats 2–16

Cab 2–19

Cab air conditioning system 2–27

Transmission with range gear – 30 km/h (19 mph) 2–31

Transmission with range gear and shuttle– 30 km/h (19 mph) 2–33

Transmission with creeper and shuttle– 30 km/h (19 mph) 2–36

Mechanically controlled four wheel drive 2–39

Mechanically controlled differential lock 2–40

Towing the tractor2–42

Loading the tractor onto a transporter 2–42

Checks before using the tractor 2–43

Section 3 – Field Operation

Starting with thermostart the engine3–3

Power take–off 3–5

Hydraulic lift3–17

Three–point linkage Cat II 3–22

Remote control valves 3–29

Wheel track adjustment3–31

Tyres 3–38

Tyre combinations3–42

Ballasting 3–49

Static weight distribution3–50

Section 4 – Lubrication and Maintenance

Access for inspection and maintenance 4–4

Lubrication and maintenance table 4–5

Flexible maintenance 4–7

When the warning light is on 4–9

10–hour / daily service 4–10

50–hour service 4–15

300–hour service 4–18

600–hour service 4–23

900–hour service 4–23

1200–hour service4–23

1200–hour or every 2 years service4–26

General maintenance 4–30

Electrical system 4–32

Recommendations for bodywork maintenance 4–39

Lubricant capacities and specifications 4–40

Section 5 – Fault Finding

Introduction 5–1

Engine 5–2

Electrical system 5–5

Hydraulic system 5–6

Three-point linkage5–7

Brakes 5–8

Cab 5–8

Section 6 – Vehicle Storage 1–1

Section 7 – Accessories

Beacon lamp 7–2

Drawbars and towing attachments 7–3

Hydralic trailer brake 7–9

Section 8 – Specifications

General Dimensions 8–2

Weights8–4

Engine specifications 8–5

Timing 8–6

Fuel system 8–6

Lubrication 8–7

Cooling system 8–7

Transmission8–7

Power take–off 8–8

Hydraulic system 8–8

Three-point linkage8–9

Front axle 8–9

Steering 8–10

4WD front axle 8–10

Brakes8–11

Bodywork and driving position8–11

Towing devices 8–11

Electrical system 8–12

Section 9 – First 50–hour Service Forms 9–1

Section 10 – Index

INDEX DETAILS:

Case IH New Holland TD 60D 70D 80D 90D 95D Operators Manual

INDEX

Section – Page Section – Page

A

Access panels 4–4

Air cleaner 2–5, 4–9, 4–20, 4–24

Air conditioner2–15, 2–27, 4–13

Antifreeze 4–40

Attaching equipment 7–3

B

Ballasting3–54, 5–8

Battery 4–11

Battery charging 4–32

Beacon lamp 2–14, 2–23, 4–33, 7–2

Before operating the tractor2–43, 3–1

Belt adjustment4–8

Bleeding the fuel injection system 4–30

Bonnet 2–2, 4–4

Brake fluid level 4–10

Brakes2–14, 4–7, 8–11

Bulb replacement 4–37

C

Cab2–19

Cab air filters 2–26, 4–13, 4–24

Cab heater 2–15, 2–26

Cab maintenance4–39

Cast iron weights 3–49

Changing PTO output shaft 3–9

Charging the battery 4–32

Cigarette lighter 2–11

Cleaning the tractor1–1

Clutch 2–14, 4–7, 8–7

Combined position and draft control3–20

Connecting remote cylinders3–29

Controls and instruments 2–4

Coolant 4–27, 4–40

Coolant temperature gauge2–10, 2–8

Cooling system 4–27, 8–7

Creeper gears2–36

D

Dryer filter 4–14

Diesel fuel 4–2

Differential lock2–14, 2–40

Dimensions 8–2

Direction indicators 2–10, 2–5

Door handle 2–20

Double acting cylinders3–29,3–30

Draft control 3–19

Drain fuel/water separator 4–10

Drawbars and towing attachments 7–3

Drive belts 4–8

Dry air cleaner 2–5, 4–9, 4–20, 4–24

E

Ecology and the environment1–5

Electrical equipment – specification8–12

Electrical relays 4–34

Engine air cleaner 2–5, 4–9, 4–20, 4–24

Engine coolant temperature gauge 2–5, 2–8

Engine oil change4–18

Engine oil filter4–19

Engine oil level4–10

Engine specification 8–5

Engine tachometer 2–10, 2–5, 2–8

Engine valve clearance 4–23

Engine coolant4–27

F

Fan belt 4–8

Fan guards 2–2

Fault finding

Brakes5–8

Cab5–8

Electrical system5–5

Engine5–2

Hydraulic system5–6

Three–point linkage 5–7

Final reduction gears 4–20, 4–29

First 50 hour service 1–1, 9–1

Flexible maintenance 4–7

Float operation3–19

Fluid capacities and specification 4–40

Folding roll bar3–28

Foot throttle 2–14

SECTION 10 – INDEX

10–2

Footbrakes2–14

Four wheel drive 2–13, 2–39, 8–10

Four wheel drive

maintenance 4–15, 4–21, 4–25, 4–26

Front mudguards 3–37

Front track adjustment

Four wheel drive3–33

Two wheel drive3–31

Front weights 3–49

Front wheel bearings – two wheel drive4–22

Fuel filter 2–5, 4–17, 4–18

Fuel injectors4–26, 8–6

Fuel level gauge 2–5, 2–8

Fuel pump filter 4–18

Fuel sedimenter 4–10

Fuel storage4–2

Fuel system bleeding4–30

Fuel tank 4–24

Fuelling the tractor 4–2

Fuse box 4–34

G

Gauges2–10

Gear levers2–12

General information2–1

General maintenance4–30

Grease fittings4–10

Ground drive PTO3–7

Ground speed charts 2–32, 2–34, 2–37, 3–10

Guards2–2, 3–5

H

Hand throttle 2–10

Handbrake 2–13, 2–5, 2–7, 4–21

Hazard warning lights2–11

Headlights2–10, 2–5, 2–6, 2–9, 4–36

Heater 2–15, 2–26

Hood 2–2, 4–4

Horn 2–10, 2–9

Hourmeter 2–10, 2–5, 2–8

Hydraulic oil filter 4–19

Hydraulic controls2–12

Hydraulics3–17, 4–15, 8–8

Hydraulics/rear axle/–

transmission oil4–20, 4–29, 4–29

Hydraulic trailer brakes7–9

Hydrostatic steering 4–12, 4–19, 4–25

I

Ignition key 2–11, 3–3

Indicator and warning lights2–10, 2–5, 2–6, 2–7

Injectors 4–26

Inspection panels 4–4

Instrument console 2–11

Instrument panel2–10, 2–5, 4–38

International symbols1–15

Introduction 2–1

K

Key start switch 2–11, 3–3

L

Lift–o–Matic control 3–17

Lift rods 3–23, 7–5

Lights switch 2–10, 2–9

Liquid ballast 3–50

Lower links3–27

Lubricant capacities and specifications4–40

Lubrication and maintenance chart 4–5

O

Operating the PTO 3–5

Operating the tractor 3–2

P

Parking brake 2–13 2–5, 2–7, 4–21

Parking lights2–11, 2–9

Position control 3–18

Power take–off 1–9, 2–13, 3–5, 8–8

Power take–off guard and safety cap 2–3, 3–5

Pre–operation checks 3–1

Precautionary statements1–6

Preparation for use after storage1–1

Product identification 1–2

Proofmeter2–10, 2–5, 2–8

R

Radiator4–12

Radio2–15, 2–25

Rear axle/hydraulics/–

transmission oil4–20, 4–29, 4–29

Rear tow hitches 7–4

Rear view mirrors 2–21, 2–22

Rear wheel track adjustment3–33

SECTION 10 – INDEX

10–3

Rear wheel weights 3–49

Rear window 2–21

Relays 4–34

Remote control valves2–12, 3–29

Road speed charts2–32, 2–34, 2–37, 3–10

Roll bar3–28

Rotating beacon 2–14, 2–15, 7–2

Running in procedure 4–1

S

Safety cab 1–11, 2–19

Safety chain 2–42

Safety covers and guards2–2

Safety decals 1–12

Safety precautions 1–6

Seat2–16

Seat belt 2–18

Service parts 1–1

Servicing the tractor 4–5

Shuttle lever2–13, 2–33

Side lights 2–5, 2–6, 2–7, 2–9, 4–37

Side windows 2–21

Single acting cylinders 3–30

Stabilisers 3–24

Starter motor cover2–2

Starting the engine 3–2, 3–4

Starting with jump leads 4–33

Steering 2–10, 2–16, 4–12, 4–15

4–19, 8–10, 4–25

Steering stops3–37

Stopping the engine 3–2, 3–4

Storing the tractor 1–1

Sun visor 2–22

Swinging drawbars7–3

Synchro Command transmission 2–31

Synchro Shuttle transmission2–33, 2–36

T

Tachometer 2–10, 2–8

Telescopic stabilisers3–24

Temperature gauge 2–10

Thermostart 2–11, 3–3

Three point linkage 3–22, 8–8

Three point linkage – fault finding5–7

Three point linkage–lift capacity 8–9

Three speed PTO3–8

Throttle 2–10, 2–14

To the owner1–1

Top link3–23

Tow hitches 7–3

Towing the tractor2–42

Track adjustment

Four wheel drive3–33

Two wheel drive3–31

Tractor dimensions8–2

Tractor identification 1–2

Tractor lights 2–10, 2–9

Tractor storage 1–1

Tractor weight 8–4

Tractor weighting3–54, 8–4

Trailer brakes 7–9

Transmission 2–31, 2–31, 2–33, 2–36, 8–7

Transmission oil capacity4–40

Transmission/hydraulics/–

rear axle oil4–20, 4–29, 4–29

Transporting the tractor 2–42

Turn signals 2–10, 2–5, 2–6, 2–7

Two speed PTO 3–8

Tyre combinations 3–42, 3–47

Tyre loading information 3–39

Tyre maintenance3–38

Tyre pressures 3–40, 3–44, 3–48

V

Valve clearance 4–23

Vehicle identification plate1–2

Vehicle storage1–1

Ventilation 2–25

W

Warning beacon 2–14, 2–15, 7–2

Warning lights2–10, 2–5, 2–6, 2–9, 4–38

Warranty1–1

Water separator 4–10

Weight 8–4

Welding1–11

Wheel bearings 4–22

Wheel nut torques3–31

Windows 2–21

Windscreen wiper/washer2–15, 2–24, 4–12

Worklights 2–15, 2–22, 2–23

PLEASE NOTE:

⦁ This is not a physical manual but a digital manual – meaning no physical copy will be couriered to you. The manual can be yours in the next 2 mins as once you make the payment, you will be directed to the download page IMMEDIATELY.

⦁ This is the same manual used by the dealers inorder to diagnose your vehicle of its faults.

⦁ Require some other service manual or have any queries: please WRITE to us at [email protected]