case 580K phase3 Loader Backhoe service Manual

SCREENSHOT OF THE MANUAL:

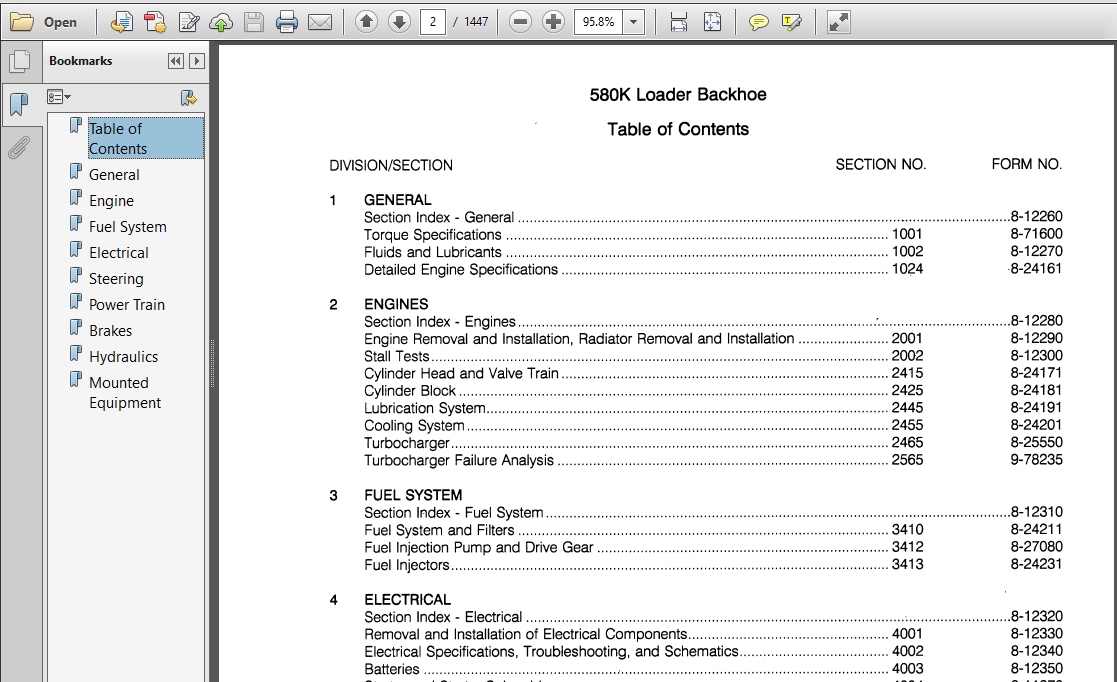

TABLE OF CONTENTS:

- case 580K phase3 Loader Backhoe service Manual

1 GENERAL

Section Index – General

Torque Specifications

Fluids and Lubricants

Detailed Engine Specifications

2 ENGINES

Section Index – Engines

Engine Removal and Installation Radiator Removal and Installation

Stall Tests

Cylinder Head and Valve Train

Cylinder Block

Lubrication System

Cooling System

Turbocharger

Turbocharger Failure Analysis

3 FUEL SYSTEM

Section Index – Fuel System

Fuel System and Filters

Fuel Injection Pump and Drive Gear

Fuel Injectors

4 ELECTRICAL

Section Index – Electrical

Removal and Installation of Electrical Components

Electrical Specifications Troubleshooting and Schematics

Batteries

Starter and Starter Solenoud

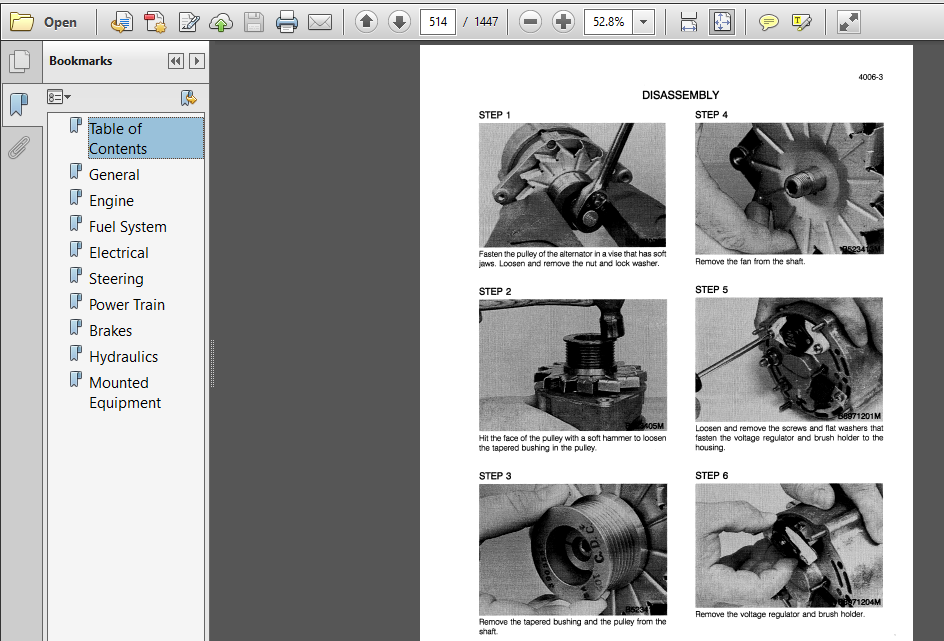

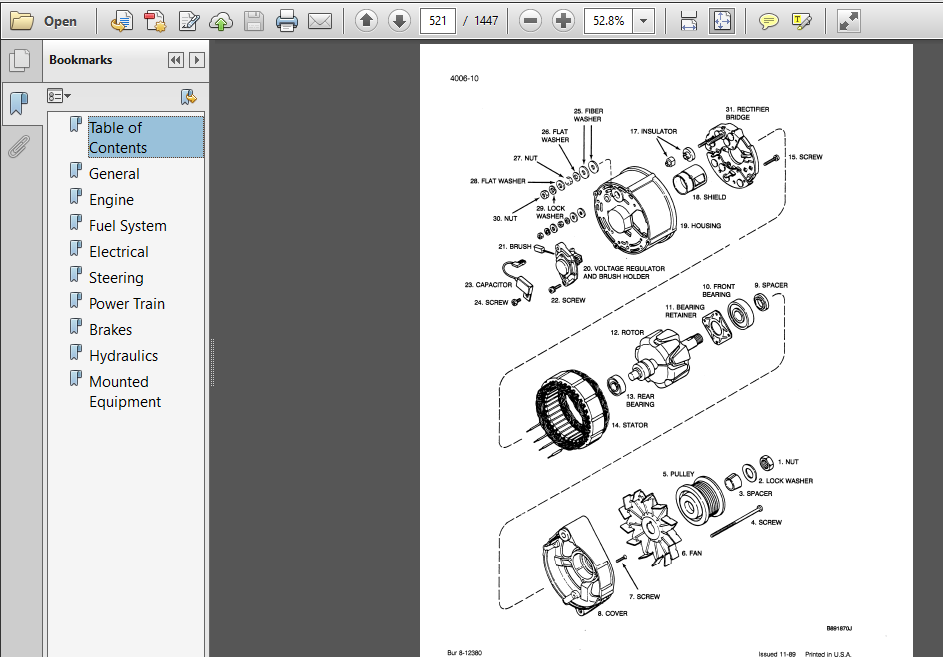

65 Ampere Alternator

95 Ampere Alternator

Electrical Instrument Control Center

5 STEERING

Section Index – Steering

Removal and Installation of Steering Components

Specifications Schematic, and Troubleshooting

Optional Tilt and Telescoping Steering Column

Steering Control Valve – Eaton

Steering Control Valve – Danfoss

Steering Cylinders

Front Axle – Two Wheel Drive

Front Axle – Four wheel Drive

6 POWER TRAIN

Section Index ~ Power Train

Removal and Installation of Power Train Components

Transmision Specifications and Schematic

Wheels and Tires

Rear Axles and Planetaries

Transfer Gearbox

Differential and Differential Lock

Fonivard/Reverse Valve

Torque Converter Charging Pump Output Shaft and

Converter Housmg

Transmissmn

7 BRAKES

Section Index – Brakes

Parking Brake

Disc Brakes

Removal and Installation of Brake Components

Master Cylinder

8 HYDRAULICS

Section Index – Hydraulics

Removal and Installation of Hydraulic Components

Hydraulic Schematics Specifications and Troubleshooting

Cleaning the Hydraulic System

Hydraulic Pump

Loader Control Valve

Cylinders

Backhoe Control Valve

Swing Sequence Valve

Three Point Hitch Control Valve

Double Selector Valve

9 MOUNTED EQUIPMENT

Section Index – Mounted Equment

Pedals and Levers

Air Conditioning Troubleshooting and Pressure Checks

Air Conditioning System

Loader

ROPS Cab and ROPS Canopy

Backhoe – Integral

Backhoe – Demountable

Three Point Hitch

Seat and Seat Belts

Suspension Seat

VIDEO PREVIEW:

DESCRIPTION:

Engine Lubrication:

Fill the engine crankcase with CC or CD service classification oil that has the correct viscosity rating for the ambient air temperature. Install new oil filters, after the engine has been rebuilt.

Run-In Procedure For Rebuilt Engine:

Step 1 Disconnect the wire to the electric shut—off on the injection pump so that the engine will not start. Crank the engine for 30 seconds until there is oil pressure. then reconnect the wire.

Step 2 Remove the air from the cooling system at the temperature sending unit.

Step 3 Run the engine at 1000 RPM minimum load for 5 minutes and check for oil leaks.

Step 4 During the Run-In. continue to check the oil pressure. coolant level. and coolant temperature.

PLEASE NOTE:

⦁ This is the SAME MANUAL used by the dealerships to diagnose your vehicle

⦁ No waiting for couriers / posts as this is a PDF manual and you can download it within 2 minutes time once you make the payment.

⦁ Your payment is all safe and the delivery of the manual is INSTANT – You will be taken to the DOWNLOAD PAGE.

⦁ So have no hesitations whatsoever and write to us about any queries you may have : heydownloadss @gmail.com11