Case 580C Loader Backhoe Service Manual – PDF Download !!

IMAGES PREVIEW:

VIDEO PREVIEW:

DESCRIPTION:

Before making any repairs or adjustments on an engine, a mechanic or technician must properly diagnose the trouble. Locating the trouble and repairing it is only part of the job. a technician must find and eliminate the cause of the trouble as well. Too many repairs are made with no thought to removing the causes that made the repair necessary. For any engine to start or perform properly, three main requirements must be present: 1.FUEL 2.COMPRESSION 3.COMBUSTION

When any of these requirements are not pre- sent or limited by some mechanical reason. the engine will not start and will fail to operate properly throughout the power range. FUEL. Fuel system problems can be present anywhere from the fuel tank. through the fil- ters and injection pump as well as the injec- tors. Correct injection pump timing is impor- tant in the overall fuel system performance.

COMPRESSION. Compression on an engine is related to the “breathing function”. Proper compression is affected by the air cleaner condition, muffler restriction, valve condition and operation including proper valve adjust- ment, cylinder head gaskets, condition of sle- eves. rings, pistons. camshaft, and camshaft timing.

COMBUSTION. Combustion is the result of ade- quate compression to develop enough heat in the air charge on the compression stroke to fire the fuel being injected into the engine cylinders. PrOper spray pattern and atomization of the fuel by the injector is very important. Timing the fuel injection pump to the engine to a pre- cise degree BTDC is a vital requirement for proper combustion.

The engine diagnosis contained in the follow- ing pages covers many trouble symptoms. the causes, and what will be necessary to repair or eliminate the problem. Under each symp- tom are listed the most common and reoccur- ing problems progessing to the not so com- mon problems. Locate your problem symp- tom in the diagnosis chart and refer to the pages listed for the probable causes and re- medies. .

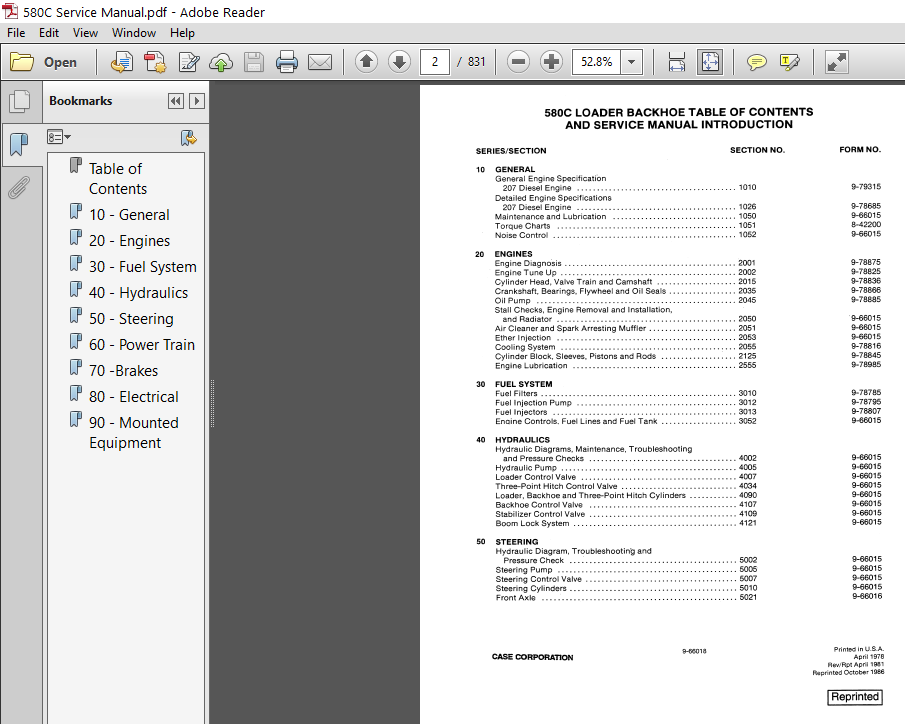

TABLE OF CONTENTS:

Case 580C Loader Backhoe Service Manual – PDF Download !! Publication Number: 9-66018

- GENERAL

General Engine Specification

207DieseiEngine

Detailed Engine Specifications

207Diesel Engine

Maintenance and Lubrication

Torque Charts

Noise Control - ENGINES

Engine Diagnosis

Engine Tune Up

Cylinder Head, Valve Train and Camshaft

Crankshaft Bearings Fly wheel and Oil Seals

Stall Checks Engine Removal and Installation, and Radiator

Air Cleaner and Spark Arresting Muffler

Ether lnjection

Cooling System

Cylinder Block, Sleeves, Pistons and Rods

Engine Lubrication - FUEL SYSTEM

FueI Filters

Fuel injection Pump

Fuel lnjectors

Engine Controls Fuel Lines and Fuel Tank - HYDRAULICS

Hydraulic Diagrams, Maintenance, Troubleshooting and Pressure Checks

Hydraulic Pump

Loader ControI Valve

Three-Point Hitch Control Valve

Loader Backhoe and Three Point Hitch Cylinders

Backhoe Control Valve

Stabilizer Control Valve

BoomLockSystem - STEERING

Hydraulic Diagram Troubleshooting and

Pressure Check

Steering Pump

Steering Control Valve

Steering Cylinders

Front Axle - POWER TRAIN

Power Shuttle Operation Oil Flow Diagrams

Troubleshooting and Maintenance

Power Shuttle and Torque Converter

Shuttle Controls (Power and Mechanical)

Transaxle Removal and Installation

Transaxle and Differential Lock

DriveShaft

WheelsandTires

CIutchandPressurePlate

Two Speed Mechanical Shuttle - BRAKES

Brakes (Pedals to Transaxle)

Self Adjusting Differential Brakes - ELECTRICAL

Troubleshooting

WiringDiagrams

Instrument Panel and Instrument Cluster

Battery

Starterand StarterSolenoid

NippondensoStarter

Alternator

ElectricalAccessories - MOUNTED EQUIPMENT

Loader

Three-Pointi-Iitch

ROPSCabandCanopy

Backhoe

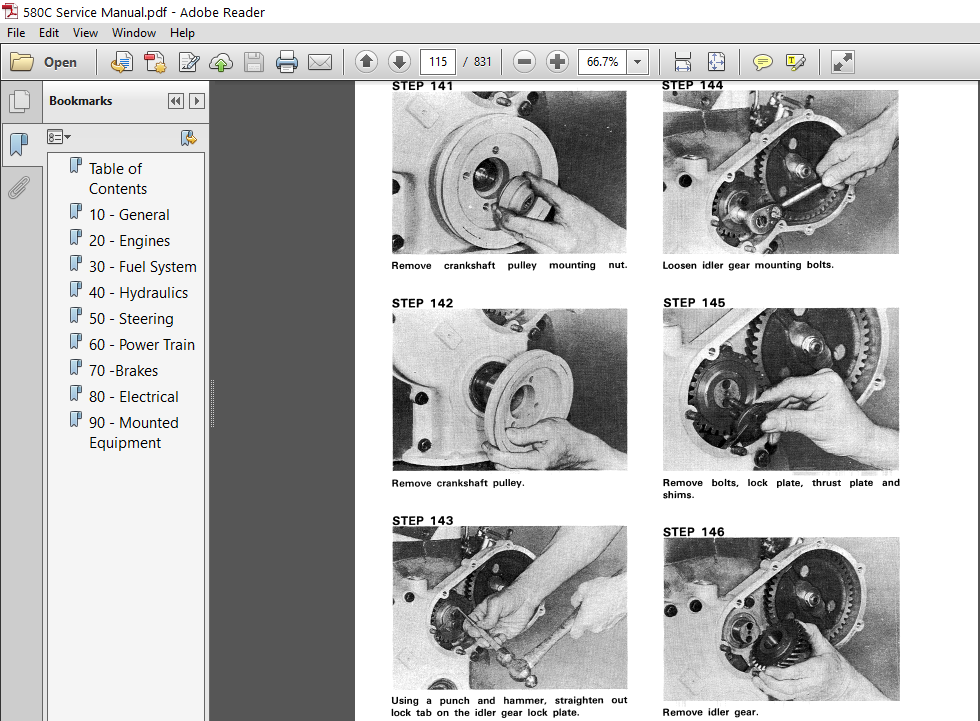

SAMPLE PAGE:

- Listed below are checks that must be performed to insure continuing noise protection

- Check that all exterior parts and sheet metal fasteners are tight. All rattles close to the operator’s area must be eliminated. .

- Check that ‘all sealing and barrier ma- terials are whole and intact. A small hole can admit a large amount of noise.

- Check noise isolators such as engine mounts, rubber shock mounts, hydraulic tube isolators, etc. Replace if defective.

- Check that the full throttle – no load engine speed is checked with an ac- curate tachometer. The engine speed must be within the limits as listed in Section 1010.

- Check the full range of engine speed for resonance (loud, undampened vibra- tion). To check, increase the engine speed from low idle to full throttle slowly.

- If excessive resonance is found. eliminate the vibration of the suspected part.

PLEASE NOTE:

⦁ This is the same manual used by the dealers to diagnose and troubleshoot your vehicle.

⦁ You will be directed to the download page as soon as the purchase is completed. The whole payment and downloading process will take anywhere between 2-5 minutes.

⦁ Need any other service / repair / parts manual, please feel free to contact [email protected] . We still have 50,000 manuals unlisted.