2017 Massey Ferguson MF7344 Combine Harvesters Operator’s Manual – PDF DOWNLOAD

DESCRIPTION:

2017 Massey Ferguson MF7344 Combine Harvesters Operator’s Manual – PDF DOWNLOAD

INTRODUCTION:

- Your new self-propelled combine is manufactured for harvesting seed and cereal crops, for threshing, separating, cleaning and conveying the grain into the tank and depositing the straw on the ground. This Operator’s Manual should be used as a practical reference guide: It contains all the necessary practical information for the operation, adjustment and maintenance of your new machine.

- Your combine was designed and built to ensure optimum performance, comfort and ease-of-operation in a wide variety of crops and conditions. The combine has been thoroughly inspected prior to delivery both at the factory and by your Dealer, to ensure you receive it in perfect condition. To keep the combine in perfect condition and to ensure trouble-free performance, the periodical maintenance operations listed in this manual should be carried out at the recommended intervals.

- Before operating and/or driving the combine, read this Operator’s Manual carefully, paying particular attention to the section on safety rules. Always keep this manual on hand for further reference. The terms “left” and “right” are always used with reference to the machine travelling direction. Should you require further information about the machine, please do not hesitate to contact your authorised Dealer. Your Dealer provides specially trained personnel, genuine quality spare parts and the required tools to solve any problems that may arise.

- The genuine spare parts and accessories have been specifically designed for this type of machine. Only genuine parts supplied by your authorised Dealer can guarantee correct operation and optimum performance. Never use non-genuine spare parts or accessories: Some accessories (e.g. PTO shafts, straw choppers, tables) require an EC certification, which can be provided only by the manufacturer or his qualified and recognised sub-suppliers.

- Non-genuine spare parts have not been tested and are not authorised by the manufacturer. The fitting and/or use of such equipment may have a damaging effect on the design features of the machine and jeopardise operational safety. The manufacturer disclaims all liability in the event of loss or damage arising as a result of non-genuine parts, accessories or equipment being used. It is expressly prohibited to make any modification to the combine without the prior written authorisation by the manufacturer.

TABLE OF CONTENTS:

2017 Massey Ferguson MF7344 Combine Harvesters Operator’s Manual – PDF DOWNLOAD

1 General Information 1 3

1 1 Information 15

1 1 1 Introduction 1 5

1 1 2 Company policy 1 5

1 1 3 Optional equipment 1 5

1 1 4 Spare parts and accessories 1 6

1 1 5 Warranty 1 6

1 1 6 Lubricants 1 6

1 2 Use 1a

1 2 1 Use of the combine 18

1 3 Identification 19

1 3 1 Combine identification 19

1 3 2 Engine Identification 20

1 3 3 Cutting table identification 2 1

1 3 4 Cab identification 2 1

1 3 5 Hydrostatic pump identification 22

1 3 6 Hydrostatic motor identification 22

1 3 7 Straw chopper identification (if fitted) 2 3

1 3 8 Chaff spreader identification (if fitted) 2 3

1 3 9 Trailer hitch identification (if fitted) 2 4

1 4 Identification form 25

1 4 1 Machine data 2 5

1 5 Conformity 26

1 5 1 EC Declaration of Conformity 2 6

1 6 Information 2 7

1 6 1 Ecology 27

1 6 2 Hydraulic systems: hoses 27

1 6 3 Scrapping and disposal 28

1 7 Weight 29

1 7 1 Weight distribution 29

2 Safety 31

2 1 Warning symbols and safety instructions 33

2 1 1 Warnings 3 3

2 2 Information for road transport 3 4

2 2 1 Road transport 3 4

2 3 Information for operations 37

2 3 1 Field Operations 3 7

2 4 Information for maintenance 4 1

2 4 1 Maintenance work 4 1

2 5 Information on the engine 4 5

2 5 1 Engine 4 5

2 6 Safety and function decals 4 9

2 6 1 Location of decals 4 9

2 6 2 Description of decals 53

2 7 Work on the battery 6 4

2 7 1 Battery 6 4

2 8 Safety devices 65

2 8 1 Emergency exit 6 5

Combine Harvester

MF 7344_EN_LA327433011

Table of contents

2 8 2 Operator presence device 6 6

2 8 2 1 Returning the machine to normal operation 6 7

2 8 3 Safety belts 6 8

2 8 4 Cutting table safety stops 6 9

2 8 5 Safety guard for main crop elevator 7 0

2 8 6 Sprags for wheels 7 0

2 8 7 Audible alarm for reversing 7 1

2 8 8 Reflectors for road transport 7 2

2 8 9 Safety Guards 7 3

2 8 10 Fall protection rails 7 3

2 8 1 1 Safety devices for operations to be carried out in the upper part of the machine 7 4

2 8 1 2 Straw Chopper (if fitted) 7 5

2 8 1 3 Fire extinguisher 7 5

2 9 Trailer hitch 7 6

2 9 1 Automatic towing hooks 7 6

2 9 2 CUNA and CE trailer hitches 7 7

2 9 2 1 Procedure for attaching and removing 7 8

2 9 2 2 Drawbar coupling 7 9

2 9 3 ROCKINGER trailer hitch 7 9

2 9 3 1 Removal 7 9

2 9 3 2 Drawbar coupling 8 0

2 9 4 Fixed trailer hitch (non-automatic – CUNA type) 8 1

2 10 Machine lifting 82

2 10 1 Attachment points 8 2

2 11 Towing 83

2 1 1 1 Towing the combine 8 3

2 12 Further information 84

2 12 1 Noise level in the cab 8 4

2 12 2 Vibrations in the cab 8 4

2 12 3 Statutory regulations 8 4

2 12 4 Electromagnetic emissions 8 5

2 13 Notes 86

2 1 3 1 Notes for road transport 8 6

3 Operation 89

3 1 Combine operation 9 1

3 1 1 Crop processing 9 1

3 2 Stage 1 92

3 2 1 Feeding 9 2

3 3 Stage 2 9 3

3 3 1 Threshing 9 3

3 4 Stage 3 9 4

3 4 1 Separation 9 4

3 5 Stage 4 9 5

3 5 1 Cleaning 9 5

3 6 Stage 5 9 6

3 6 1 Grain storage and unloading 9 6

4 Controls and Instruments 9 7

4 1 Steering column 9 9

4 1 1 Components and adjustments 99

4 2 Multifunction lever 1o o

4 2 1 Main components 10 0

4 3 Instrument panel 102

4 3 1 Front control panel 10 2

Combine Harvester

MF 7344_EN_LA327433011

Table of contents

4 3 2 Rear control panel 10 3

4 4 Controls at the operator seat 11 o

4 4 1 Description 1 10

4 5 Agritronicplus 111

4 5 1 Components 111

4 5 2 Multiple light indicators 1 1 2

4 5 3 On-board Computer 1 1 4

4 5 3 1 Using the computer 1 1 6

4 5 3 2 Scheduled service inspection hours 1 1 6

4 5 3 3 Resetting partial or total hectare counter 1 1 7

4 5 3 4 Calibrating constants used for calculating covered area 1 1 7

4 5 3 5 C6: Working width 1 18

4 5 3 6 C2 : Forward speed 1 18

4 5 3 7 Table of constants 1 19

4 5 3 8 Partial hectare counter 1 2 0

4 5 3 9 Hectare counter operation 1 2 0

4 5 3 10 Activation of the audible alarm 1 2 1

4 5 4 Performance monitor 1 2 2

4 5 4 1 Using the monitor 1 2 3

4 5 4 2 Selecting the measurement range (straw walker, sieves or total) 1 2 3

4 5 4 3 Calibrating the bar cursor scale 1 2 4

4 5 4 4 Sensitivity adjustment 1 2 4

4 5 4 5 Shifting to forward speed monitoring 1 2 5

4 5 4 6 Summary of keyboard functions 1 2 5

4 5 5 Terra Control System 1 2 6

4 5 5 1 Using Terra Control 1 2 9

4 5 5 2 Terra Control sensitivity 1 3 1

4 5 5 3 Calibrating the potentiometer for cutting table floatation 1 3 2

4 5 5 4 Calibrating the potentiometer for main crop elevator height control 1 3 5

4 6 Cab 1 38

4 6 1 Cab controls 1 3 8

4 6 2 Operator seat 1 4 2

4 6 3 Passenger seat 1 4 3

4 6 4 Footrest 1 4 3

4 6 5 Preparation for radio installation 1 4 4

4 6 6 Rear Cab Window 1 4 4

4 6 7 Reading light 1 4 5

4 6 8 Air conditioning in the cab 1 4 6

4 6 9 Heating 1 4 8

4 7 Access to combine components 14 9

4 7 1 Access to the operator platform 1 4 9

4 7 2 Accessing and cleaning the front windscreen of the cab 1 5 0

4 7 3 Access to the engine compartment 1 5 1

4 7 4 Access to the grain tank 1 5 2

4 7 5 Access to the inside of the grain tank 1 5 3

4 8 Engine 15 4

4 8 1 Starting the engine 1 5 4

4 8 2 Useful advice 1 5 5

4 8 3 Stopping the engine 1 5 5

4 9 Road transport 15 7

4 9 1 Operations to be carried out before transportation 1 5 7

4 9 2 Position light and sidelight adjustment 1 5 8

4 10 Using the combine 15 9

4 10 1 Operations to be carried out before use 1 5 9

5 Field Operations 16 1

Combine Harvester

MF 7344_EN_LA327433011

Table of contents

5 1 General Information 16 3

5 1 1 Notes 1 6 3

5 1 2 Before operating the machine in the field 1 6 3

5 2 Starting and Stopping the Combine 165

5 2 1 Procedure to follow 1 6 5

5 3 Cutting table 16 7

5 3 1 Attaching and removing the table 1 6 7

5 3 2 Table lateral floatation (optional) 17 1

5 3 3 GSAX system (ground self-alignment) (optional) 17 3

5 4 Main Crop Elevator 17 4

5 4 1 Adjustments 17 4

5 4 1 1 Access to the main components 17 6

5 4 2 Reverse drive system 17 7

5 5 Cylinder Housing 178

5 5 1 Components 17 8

5 5 2 Threshing drum 17 9

5 5 3 Wheat concave 18 1

5 5 3 1 Concave filler plates 18 2

5 5 3 2 Parallelism between the cylinder and concave 18 3

5 5 3 3 Unblocking the cylinder 18 4

5 5 4 Sectional concave 18 5

5 5 4 1 Concave filler plates 18 6

5 5 4 2 Parallelism between the cylinder and concave 1 8 7

5 5 5 Universal wheat/maize concave 18 8

5 5 5 1 Basic concave settings 1 8 9

5 5 6 Spike-toothed Cylinder/Concave (for rice) 1 8 9

5 5 7 Rear beater 19 1

5 6 Straw walkers 192

5 6 1 Description and adjustments 19 2

5 7 Main Grain Pan 19 3

5 7 1 Description 19 3

5 7 2 Checking the main grain pan 19 4

5 7 3 Cleaning the main grain pan 19 5

5 7 4 Stone trap assembly removal/refitting 19 6

5 8 Fanning Mill 198

5 8 1 Description and adjustments 19 8

5 8 1 1 Fanning mill for threshing light seed crops 200

5 9 Top sieve 201

5 9 1 Adjustment 20 1

5 10 Bottom sieve 205

5 10 1 Adjustment 20 5

5 11 Tailings 201

5 1 1 1 Description and adjustments 20 7

5 12 Grain tank 209

5 1 2 1 Description 20 9

5 1 2 1 1 Grain tank unloading auger 2 10

5 1 2 1 2 Sensors to check tank filling 2 1 1

5 1 2 1 3 Grain tank control window 2 1 2

5 1 2 1 4 Doors for Grain Tank Maintenance and Cleaning 2 1 2

5 1 2 1 5 Vertical auger tank drain door 2 1 4

5 1 2 1 6 Tank bottom door 2 1 4

5 1 2 1 7 Grain tank cover 2 1 6

5 1 2 1 8 Basic Settings 2 17

6 Lubrication and Maintenance 219

Combine Harvester

MF 7344_EN_LA327433011

Table of contents

6 1 General Information 221

6 1 1 Lubrication and Maintenance 22 1

6 2 Preliminary Service Inspection 22 3

6 2 1 After the first 50 working hours 22 3

6 3 Scheduled Service Inspection 224

6 3 1 Operation and adjustment 22 4

6 3 2 When and where to carry it out 226

6 3 3 Interval – 10 hours 228

6 3 3 1 Cylinder variator (1) 228

6 3 3 2 Engine oil (2) 229

6 3 3 3 Coolant expansion tank (3) 2 30

6 3 3 4 Hydraulic and hydrostatic systems tank (4) 2 30

6 3 3 5 Prefilter/water separator (5) 2 3 1

6 3 3 6 Straw chopper rotor (if fitted) (6) 2 3 1

6 3 4 Interval – 7 5 hours (Sa) 2 3 2

6 3 4 1 Service brakes (7) 2 3 2

6 3 4 2 Main crop elevator belt tensioner (9) 2 3 2

6 3 4 3 Fanning mill variator (10) 2 3 3

6 3 4 4 Belt tensioner for crop unloading auger (1 1) 2 3 4

6 3 4 5 Coupling bushes of final drive shafts (1 2) 2 3 4

6 3 4 6 Rear axle support (1 3) 2 3 5

6 3 4 7 Rear axle king pins (1 4) 2 3 5

6 3 4 8 Rear wheel 4WD tie rod (if fitted) (1 4) 2 3 6

6 3 4 9 Bearings for rear straw walker crank (1 5) 2 3 6

6 3 4 10 Bottom angle gear for unloading auger (1 6) 2 3 7

6 3 4 1 1 Top angle gear for unloading auger (17) 2 3 7

6 3 4 1 2 Table belt tensioner (18) 2 3 8

6 3 4 1 3 Angle gear at tank filling elevator (19) 2 3 8

6 3 4 1 4 Track frames (20) 2 3 9

6 3 4 1 5 Cab air filters (2 1) 2 3 9

6 3 4 1 6 Evaporator (22) 2 4 1

6 3 4 17 Condenser (2 3) 2 4 1

6 3 4 18 Radiator and hydraulic oil (2 4) 2 4 2

6 3 4 19 Adjusting the rotary screen brushes and aspirator brushes 2 4 3

6 3 4 20 Main crop elevator adapter (with lateral floatation fitted) (2 5) 2 4 4

6 3 4 2 1 Chaff spreader drive (if fitted) (26) 2 4 5

6 3 5 Interval – 1 50 hours (Sb) 2 4 5

6 3 5 1 Park brake (27) 2 4 5

6 3 5 2 Gearbox (28) 2 4 6

Combine Harvester

6 3 5 3 Reduction gear housings (29) 2 4 6

6 3 5 4 Bottom angle gear for unloading auger (30) 2 4 7

6 3 5 5 Main crop elevator supports (3 1) 2 4 8

6 3 5 6 Reversing belt tensioner arm pin (3 2) 2 4 8

6 3 5 7 Main clutch (3 3) 2 4 9

6 3 5 8 Left bearing for tailings auger (3 4) 2 4 9

6 3 5 9 Windscreen wash fluid tank (3 5) 2 50

6 3 5 10 Threshing unit belt tensioner (3 6) 2 50

6 3 5 1 1 Hydrostatic pump belt tensioner ( 3 7) 2 5 1

6 3 5 1 2 Bottom ring nut for unloading auger (3 8) 2 5 1

6 3 5 1 3 Engine air filter (3 9) 2 5 2

6 3 5 1 4 Driven belt tensioner for straw chopper (40) 2 5 3

6 3 5 1 5 Drive belt tensioner for straw chopper (4 1) 2 5 3

6 3 5 1 6 Engine (4 2) 2 5 3

6 3 5 17 Cab access ladder (4 3) 2 5 5

6 3 5 18 Straw chopper layshaft (4 4) 2 5 5

6 3 5 19 Belt tensioner for return rotary screen (4 5) 2 5 6

6 3 5 20 Rotary screen belt tensioner (4 6) 2 5 6

MF 7344_EN_LA327433011

Table of contents

6 3 6 Interval – 2 2 5 hours (Sa + engine) 2 5 6

6 3 6 1 Engine oil and filters (5 1) 2 5 6

6 3 7 Interval – 4 5 0 hours (Sc) 2 6 0

6 3 7 1 Battery (5 8) 2 6 0

6 3 7 2 Dehydrator filter (5 9) 2 6 1

6 3 7 3 Reduction gear housings (6 0) 2 6 2

6 3 7 4 Gearbox (6 1) 2 6 2

6 3 7 5 Hydraulic oil intake filter (6 2) 26 3

6 3 7 6 Filter, hydrostatic transmission (6 3) 26 4

6 3 7 7 Hydraulic systems oil (6 4) 26 5

6 3 7 8 Hydraulic and hydrostatic system return filter (6 5) 26 6

6 3 7 9 Air compressor (if fitted) (6 6) 26 7

6 3 7 10 Engine diesel oil filter (6 7) 26 7

6 3 7 11 Catalytic fluid filter (6 8) 2 6 9

6 4 Periodical maintenance operations 27 0

6 4 1 Description 2 7 0

6 4 1 1 Engine valves (1) 2 7 1

6 4 1 2 Coolant (2) 2 7 2

6 4 1 3 Service brake circuit fluid (3) 2 7 3

6 4 1 4 Diesel fuel tank (4) 2 7 3

6 4 1 5 Turbocharger (5) 2 7 4

6 4 1 6 Hydraulic hoses (6) 2 7 4

6 4 1 7 Catalytic fluid tank (DEF) (7) 2 7 5

6 5 Lubrication 27 6

6 5 1 Summary table 2 7 6

7 Adjustments 27 7

7 1 Adjustments 27 9

7 1 1 Important information 2 7 9

7 2 Belt and chain adjustment 2ao

7 2 1 Belts and chains (left-hand side) 2 8 0

7 2 1 1 Feeder drive belt (1) 2 8 1

7 2 1 2 Belt drive for threshing unit (2) 28 2

7 2 1 3 Belt drive for unloading auger (3) 28 3

7 2 1 4 Belt drive for air compressor (if fitted) (4) 28 4

7 2 1 5 Belt drive for hydrostatic pump (5) 28 5

7 2 1 6 Belt drive for chaff spreader (if fitted) (6) 28 6

7 2 1 7 Belt drive for reversing (7) 28 7

7 2 1 8 Main transmission belt (8) 2 8 7

7 2 1 9 Belt drives for good grain and tailings augers (9) 2 8 8

7 2 1 10 Belt drive for straw walkers (10) 2 8 8

7 2 1 1 1 Belt drive for cutting table (1 1) 2 8 9

7 2 1 1 2 Chain drive for unloading auger (12) 2 8 9

7 2 1 1 3 Belt drive for straw chopper (if fitted) (1 3) 2 9 0

7 2 1 1 4 Belt drive for straw chopper (if fitted) (14) 29 1

7 2 2 Belts and chains (right-hand side) 2 9 2

7 2 2 1 Belt drive for rotary screen (2 1) 2 9 2

7 2 2 2 Counter drive for rotary screen (2 2) 2 9 3

7 2 2 3 Belt drive for engine coolant pump (2 3) 2 9 3

7 2 2 4 Belt drive for alternator and cooling fan (2 4) 2 9 4

7 2 2 5 Belt drive for cylinder variator (2 5) 2 9 4

7 2 2 6 Belt drive for fanning mill variator (2 6) 2 9 5

7 2 2 7 Top chain drive for tailings auger (27) 29 6

7 2 2 8 Crop elevator chain (28) 29 6

7 2 2 9 Chain drive for tailings elevator (29) 29 7

7 2 2 10 Front crop elevator chain (3 0) 29 7

7 2 2 1 1 Chain drive for tank filling auger (3 1) 298

Combine Harvester

MF 7344_EN_LA327433011

Table of contents

7 2 2 12 Belt drive for reel pump (3 2 ) 2 98

7 2 2 1 3 Belt drive for cab air conditioning compressor (3 3 ) 2 99

7 2 2 14 Belt drive for dust aspirator (3 4 ) 300

7 3 Slip clutches 301

7 3 1 Description 3 0 1

7 3 1 1 Clutch for main crop elevator upper shaft (1) 30 1

7 3 1 2 Clutch for shaker shoe counter drive (2 ) 30 1

7 3 1 3 Shear bolt for unloading auger counter drive (3 ) 30 2

7 4 Tires 303

7 4 1 Tire pressure 3 0 3

7 4 2 Replacement of Front Wheels 3 0 4

7 4 3 Replacement of Rear Wheels 3 0 5

7 4 4 Front wheel assembly 3 0 6

7 4 5 Rear wheel assembly 3 0 7

7 5 Brakes 308

7 5 1 Service brakes 3 0 8

7 5 2 Park brake 3 0 9

7 6 Rear axle 31 o

7 6 1 Toe-in setting 3 10

7 6 2 Steering ram ball joints 3 10

7 6 3 Width setting 3 1 1

7 6 4 Telescopic arm position 3 1 1

7 6 5 Rear axle support 3 1 3

7 7 Battery 314

7 7 1 Battery Replacement 3 1 4

7 7 2 Suggestions regarding the battery 3 1 4

7 7 3 Indicator Light for Battery Charging 3 1 5

8 Systems 317

8 1 Safety Precautions 319

8 1 1 Notes 3 19

8 2 Engine supply system 320

8 2 1 Permitted fuels 3 2 0

8 2 2 Fuel Circuit 3 2 1

8 2 3 Bleeding the Fuel Supply Circuit 3 2 2

8 2 4 Catalytic fluid tank (DEF) 3 2 3

8 2 5 Injection system operation 3 2 4

8 3 Engine air intake and exhaust system 325

8 3 1 Operation 3 2 5

8 4 Engine cooling system 327

8 4 1 Coolant 3 2 7

8 4 2 Engine cooling system operation 3 2 8

8 5 Engine lubrication system 329

8 5 1 Operation 3 2 9

8 5 2 Oil vapor recovery system 3 3 0

8 6 SCR system 331

8 6 1 Operation 3 3 1

8 7 Hydraulics system 333

8 7 1 Pumps and fuel tank 3 3 3

8 7 2 Table positioning hydraulic circuits 3 3 5

8 7 2 1 Cutting table oleopneumatic shock absorbers 3 3 6

8 7 2 2 Flow limiting solenoid valve 3 3 6

8 7 2 3 Hose burst valve 3 3 7

8 7 2 4 Table horizontal positioning circuit (optional) 3 3 7

8 7 3 Reel rotation control hydraulic circuit 3 38

8 7 4 Hydraulic steering system 3 39

Combine Harvester

MF 7344_EN_LA327433011

Table of contents

8 7 5 Auxiliary hydraulics circuit 3 4 0

8 8 Hydrostatic transmission system 34 1

8 8 1 Front-wheel drive 3 4 1

8 8 2 Rear-wheel drive (optional) 3 4 2

8 9 Electrical system 34 3

8 9 1 Main components 3 4 3

8 9 2 Fuses 3 4 4

8 9 3 Additional fuses 3 4 7

8 9 4 Cab fuses 3 5 0

8 9 5 Relays 3 5 1

8 9 5 1 Additional relays 3 5 2

8 9 5 2 Various relays 3 5 3

8 9 6 Control units 3 5 5

8 9 6 1 Engine sensors and control unit 3 5 6

8 9 7 Connections for additional equipment 3 5 7

8 9 7 1 Electric connectors 3 5 7

8 9 8 Headlight adjustment 3 5 9

9 Troubleshooting 36 1

9 1 Description 36 3

9 1 1 Feeding 3 6 3

9 1 2 Threshing 3 6 3

9 1 3 Separation and cleaning 3 6 5

9 1 4 Hydrostatic Transmission 3 6 8

9 1 5 Engine 3 6 9

9 1 6 Hydraulics system 3 7 1

9 1 7 Electrical system 3 7 2

9 1 8 Air conditioning circuit 3 7 3

9 1 9 Straw chopper 3 7 3

1 O Off-Season Storage 37 7

10 1 Procedure to follow 37 9

10 1 1 Operations to be carried out after the harvest 3 7 9

10 1 2 Ordering spare parts 3 8 0

10 1 3 Operations to be carried out before the new season 3 8 0

11 Optional equipment 383

11 1 Information 385

1 1 1 1 General considerations 3 8 5

11 2 Optional equipment 386

1 1 2 1 Auxiliary table lifting ram 3 8 6

1 1 2 2 Four-wheel drive 3 8 7

1 1 2 3 Camera 3 8 7

1 1 2 4 Windbreak 3 8 8

1 1 2 5 Additional lights and mirrors 3 8 8

1 1 2 6 Electrically operated straw chopper straw deflectors 3 8 9

1 1 2 7 Additional fire extinguisher 3 8 9

1 1 2 8 Diesel fuel prefilter 390

1 1 2 9 Air compressor 390

1 1 2 10 Additional Portable Lamp 39 1

1 1 2 1 1 Weight and moisture control monitor 39 1

1 1 2 1 2 Trailer hitch 39 2

1 1 2 1 3 Refrigerator 39 2

1 1 2 1 4 Lateral floatation 39 3

1 1 2 1 5 Vertical Knifes 39 3

1 1 2 1 6 Electrically-operated sieves and returns sensors 39 4

1 1 2 1 7 Cylinder cover 39 5

Combine Harvester

MF 7344_EN_LA327433011

Table of contents

1 1 2 18 Tailings cover plate 39 5

1 1 2 19 Top sieve 39 6

1 1 2 2 0 Bottom sieve 39 7

11 3 Equipment for threshing 398

11 3 1 Equipment for maize 398

11 3 2 Equipment for corn-cob 399

11 3 3 Equipment for rice 4 00

1 1 3 4 Equipment for light seed crops 4 00

11 3 5 Equipment for soya and peas 4 01

11 4 Ballast weights 4 02

11 4 1 Description 4 02

1 1 4 2 Ballast weights on rear axle 4 03

1 1 4 3 Ballast weights on the straw walker hood for machines without straw chopper 4 04

1 1 4 4 Ballast weights on the rear wheels with a liquid mix (for tubeless tires) 4 05

1 1 4 5 Filling tires with anti-freeze solutions 4 06

11 5 Straw chopper 4 07

1 1 5 1 Transport positions 4 07

11 5 2 Working position 4 08

11 5 3 Operating the straw chopper 4 09

11 5 4 Disengaging the straw chopper 4 11

11 5 5 Access to the straw chopper rotor 4 11

11 5 6 Straw chopper rotor knives 4 11

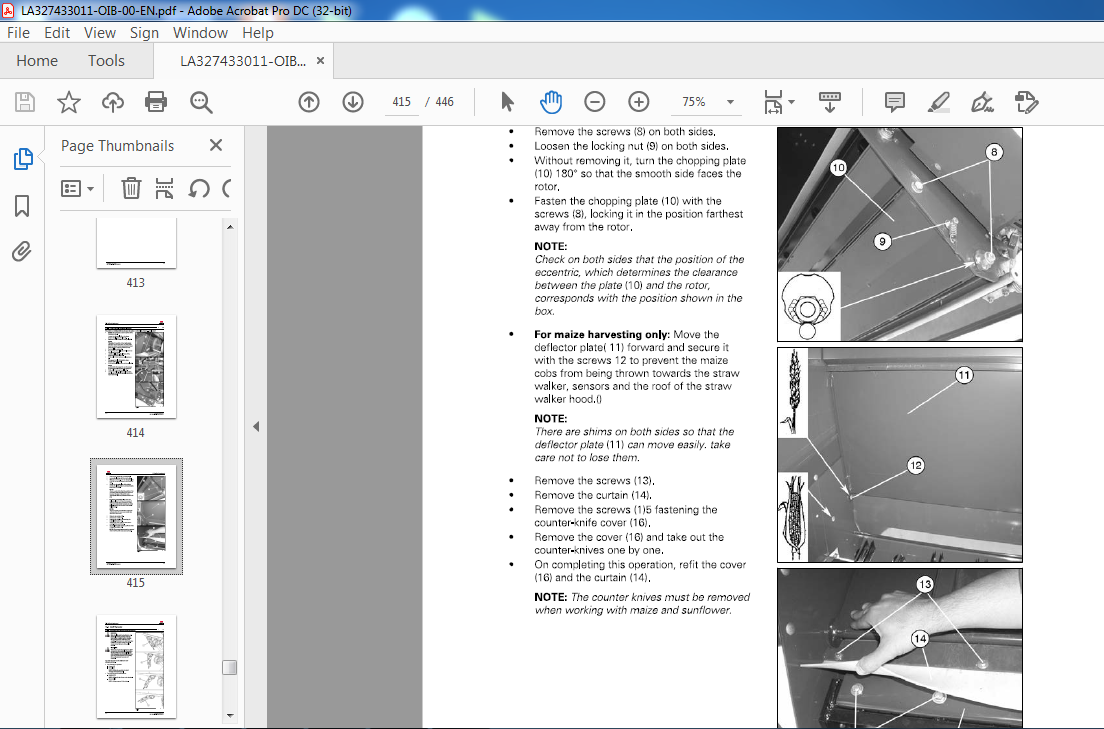

1 1 5 7 Counter-knives 4 1 2

11 5 8 Chopping quality 4 12

11 5 9 Use of straw chopper in maize 4 14

11 6 Chaff Spreader 4 16

11 6 1 Working and maintenance positions 4 16

11 6 2 Chaff spreader speed 4 18

11 6 3 Disengaging the chaff spreader 4 18

11 6 4 Chaff spreader belt tensioning 4 18

11 7 Tracks 4 19

1 1 7 1 Use and maintenance 4 19

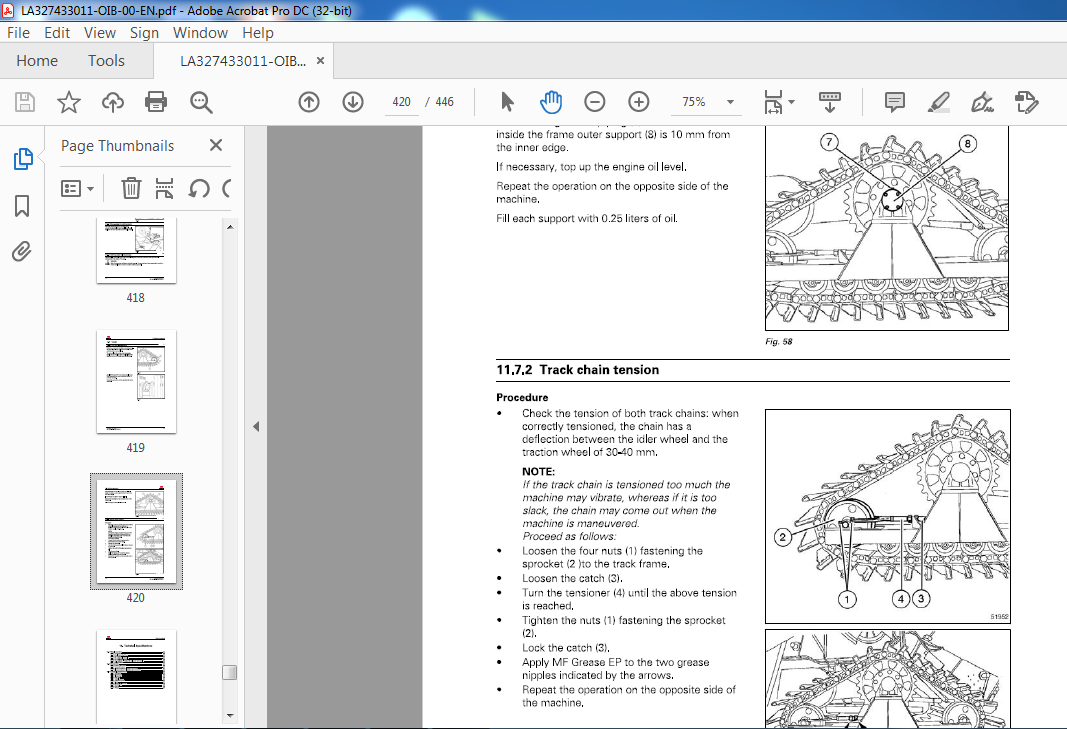

1 1 7 2 Track chain tension 4 2 0

12 Technical Specifications 421

12 1 Wheels and tires 423

1 2 1 1 information 4 2 3

1 2 1 2 Wheel tightening torque 4 2 3

1 2 1 3 Tire capacity 4 2 3

1 2 1 4 Tire equipment- front axle 4 2 4

1 2 1 5 Tire equipment – rear axle 4 2 5

1 2 1 6 Tire equipment – Version with half-tracks on front axle 4 2 6

1 2 1 7 Ballast weights 4 2 7

12 2 Dimensions 428

1 2 2 1 Combine dimensions 4 2 8

1 2 2 2 Tracks with runners 4 3 0

1 2 2 3 Clearance between unloading auger and table 4 3 1

1 2 2 4 Clearance between unloading auger and ground 4 3 2

12 3 Technical specifications 4 33

1 2 3 1 Feeding unit 4 3 3

1 2 3 2 Threshing sys 4 3 3

1 2 3 3 Cleaning unit 4 3 5

1 2 3 4 Grain tank 4 3 6

1 2 3 5 Hydraulic system 4 3 6

1 2 3 6 Hydrostatic system 4 3 7

1 2 3 7 Engine 4 3 7

Combine Harvester

MF 7344_EN_LA327433011

Table of contents

1 2 3 8 Electrical components 4 38

1 2 3 9 Transmission 4 38

1 2 3 10 Rear axle 4 39

1 2 3 1 1 Weight 4 39

13 Index 441

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the same manual used by the dealers to diagnose and troubleshoot your vehicle

- You will be directed to the download page as soon as the purchase is completed. The whole payment and downloading process will take anywhere between 2-5 minutes

- Need any other service / repair / parts manual, please feel free to contact [email protected] . We still have 50,000 manuals unlisted

s.v

Jabari –

fast, easy to download